Introduction

This is PlottyBot, a pen plotter you can build.

It’s based on a Raspberry Pi Zero W which means it’s loaded with software to make it easy to use. It also comes with novel features.

Features

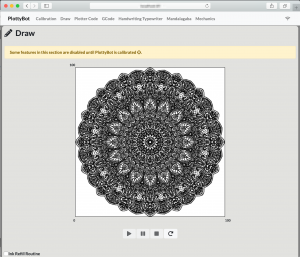

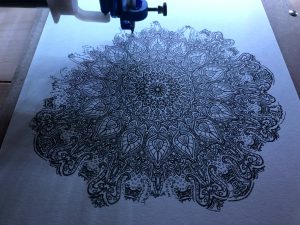

- Simple control from a web interface, with plot preview, play, pause & stop.

.

- Works on complex hours long plots without missing a step.

- Automatic calibration or manual calibration to work on smaller media.

.

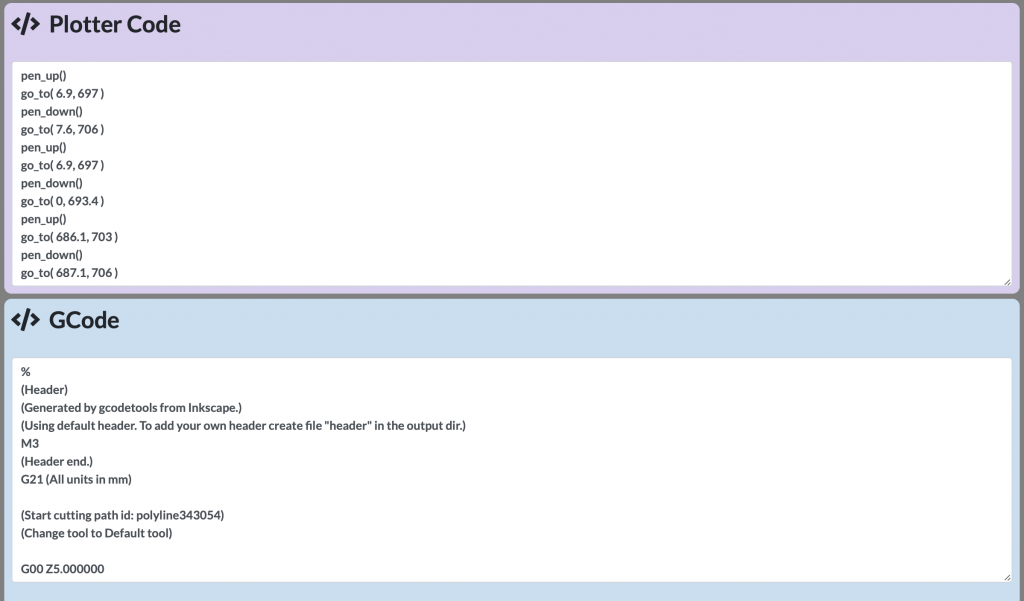

- GCode support, or simpler human readable (and kid friendly) Plotter code. Automatic conversion from GCode to Plotter code.

.

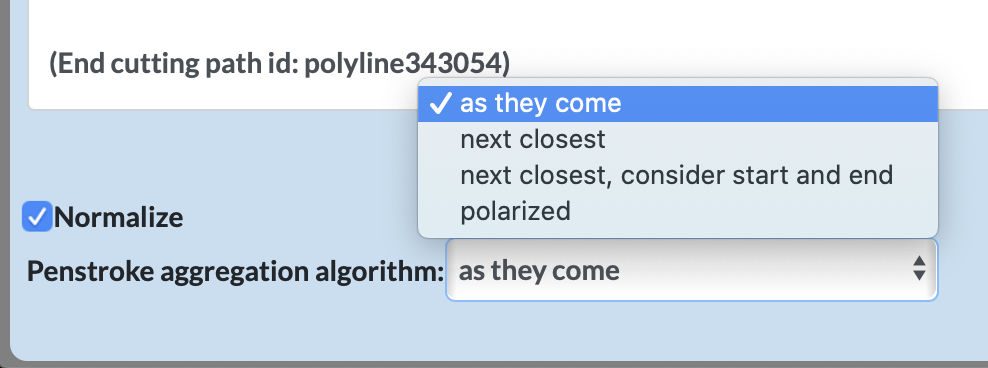

- Various pen stroke aggregation algorithms & normalization to drawing area.

.

- Internet enabled drawing

video soon to be released

- Handwriting Typewriter

- Local WiFi network where no Managed network is in range

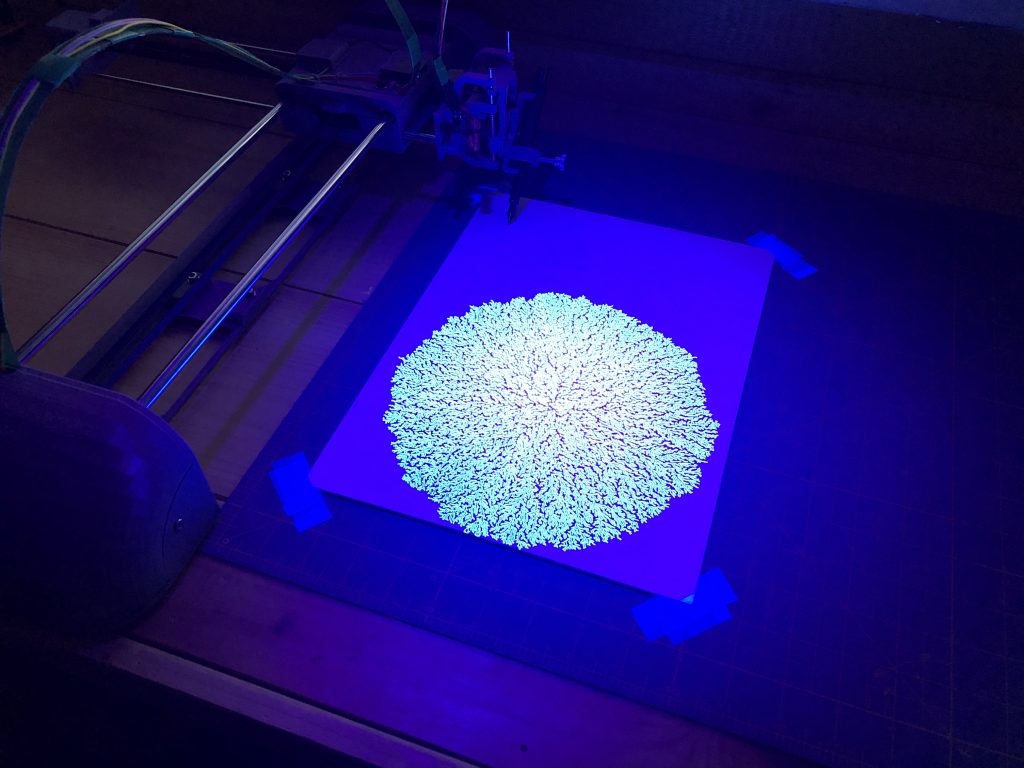

- Rotatable pen holder to accommodate various drawing instruments such as fountain pens.

.Using fountain pens gives you the ability to work with specialty inks such as UV ink.

- Ink Refill Routine for instruments which require it.

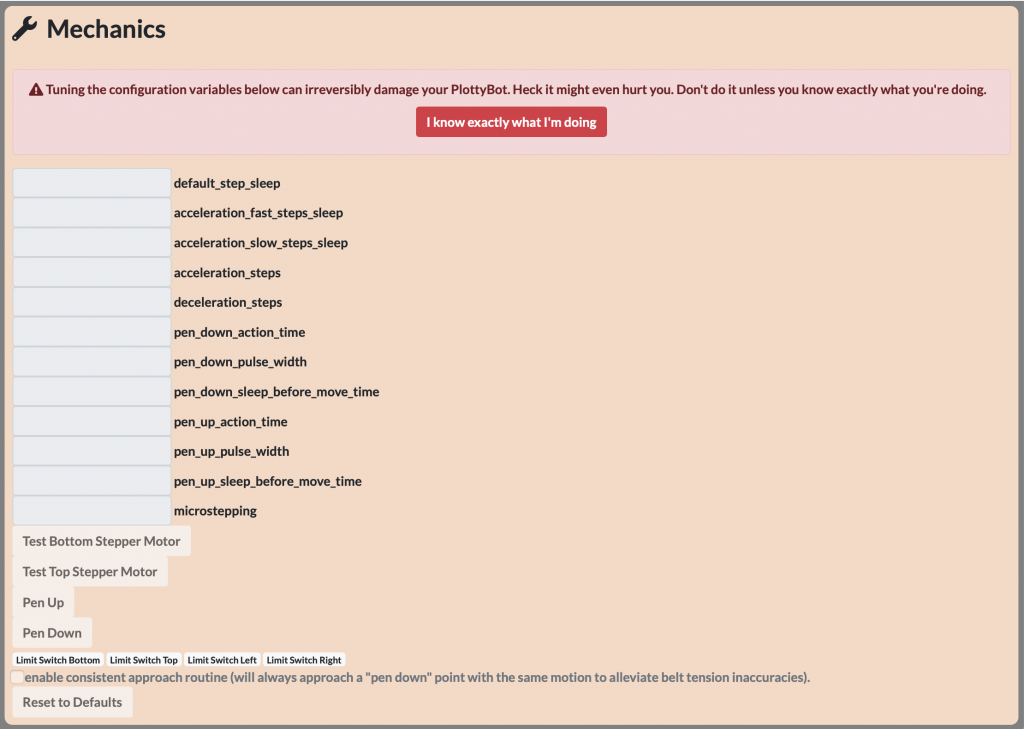

- Advanced tunables for every aspect of the machine’s operation.

.

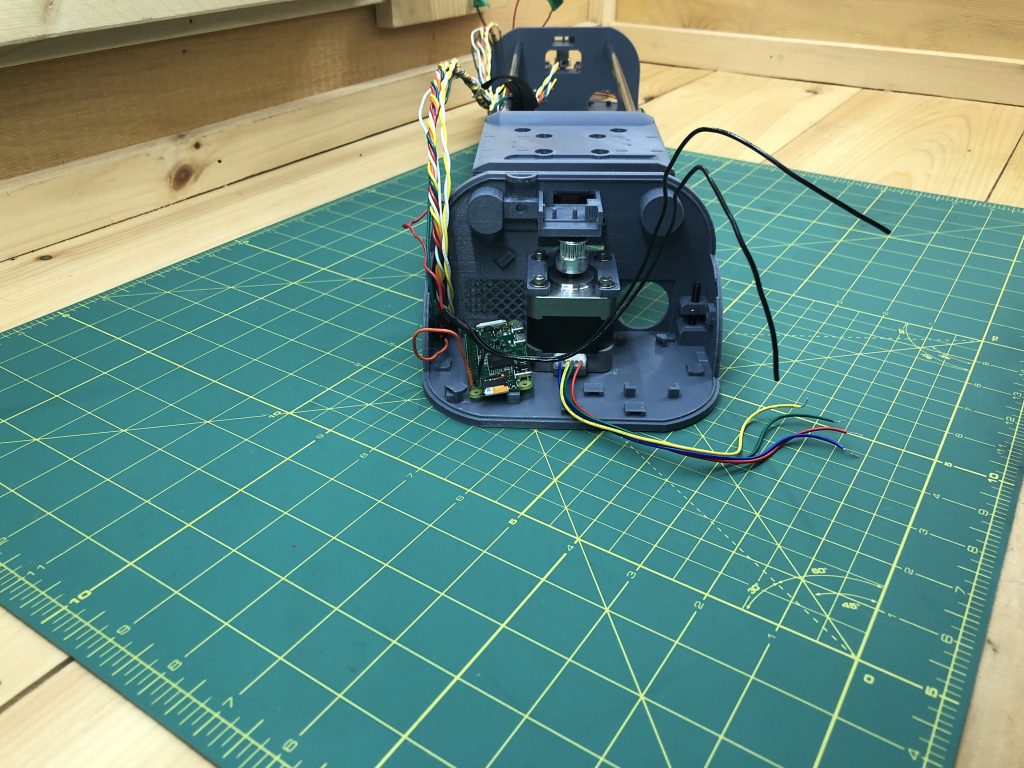

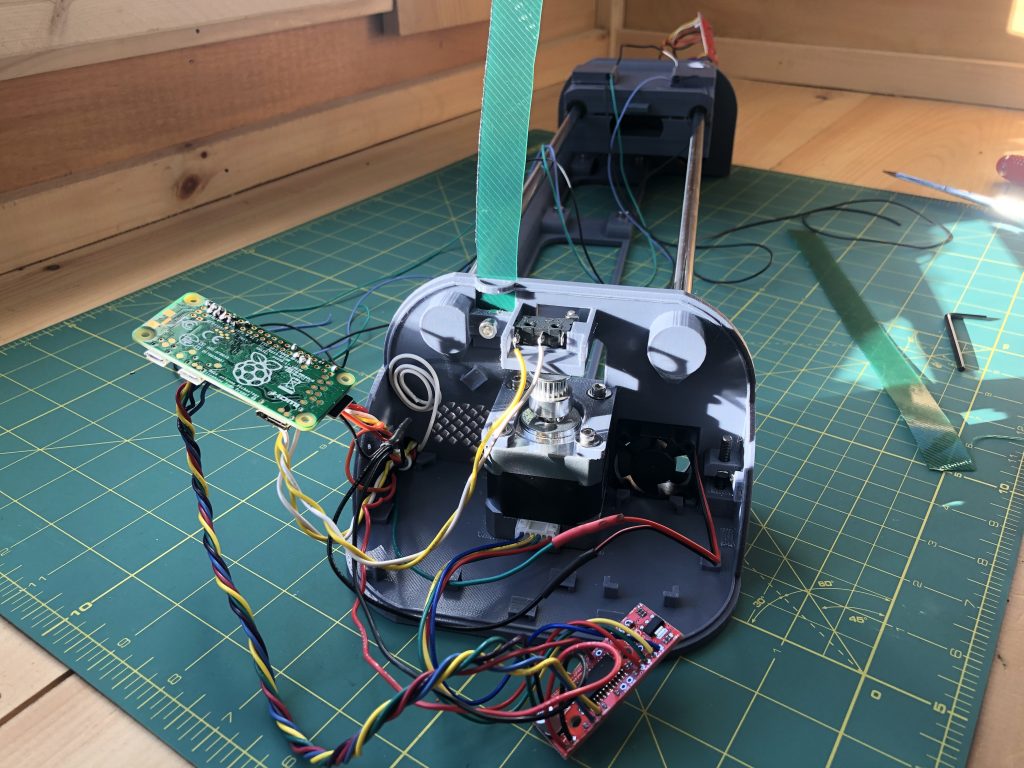

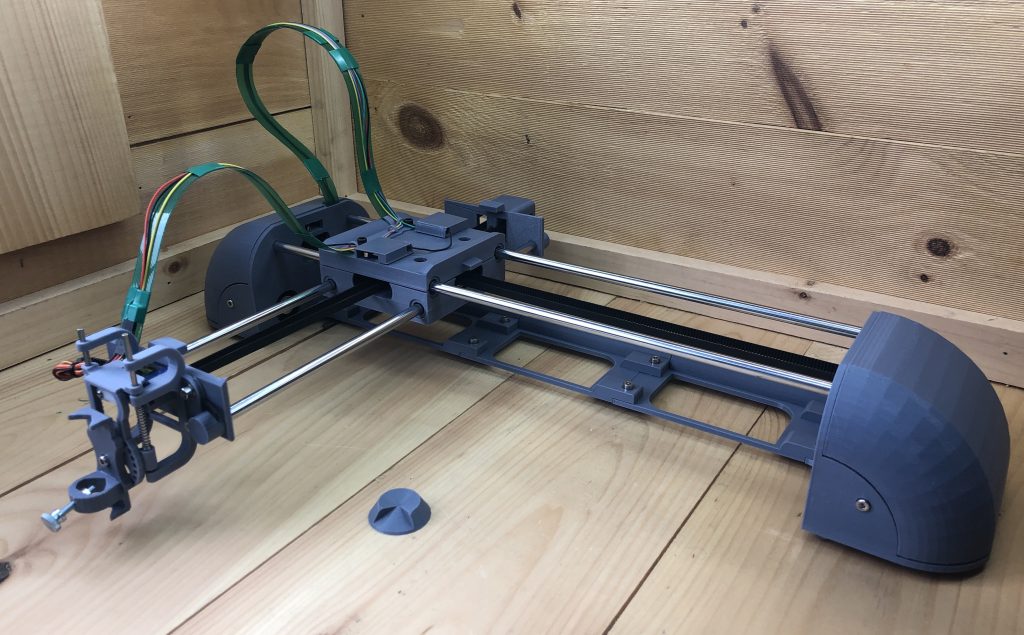

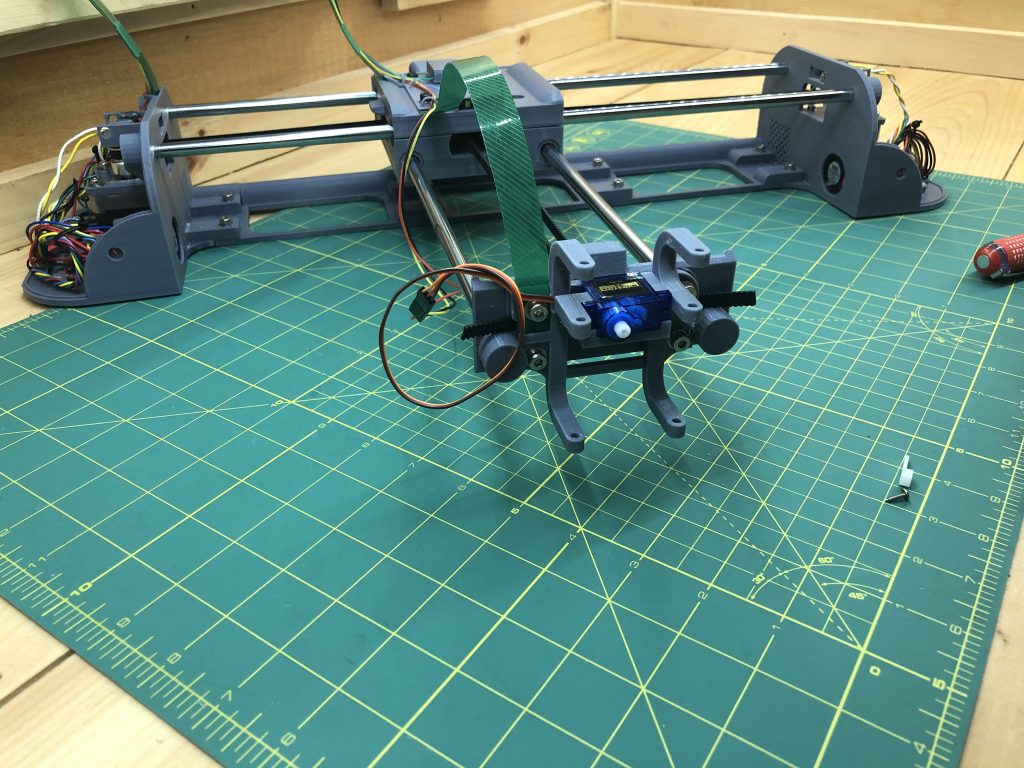

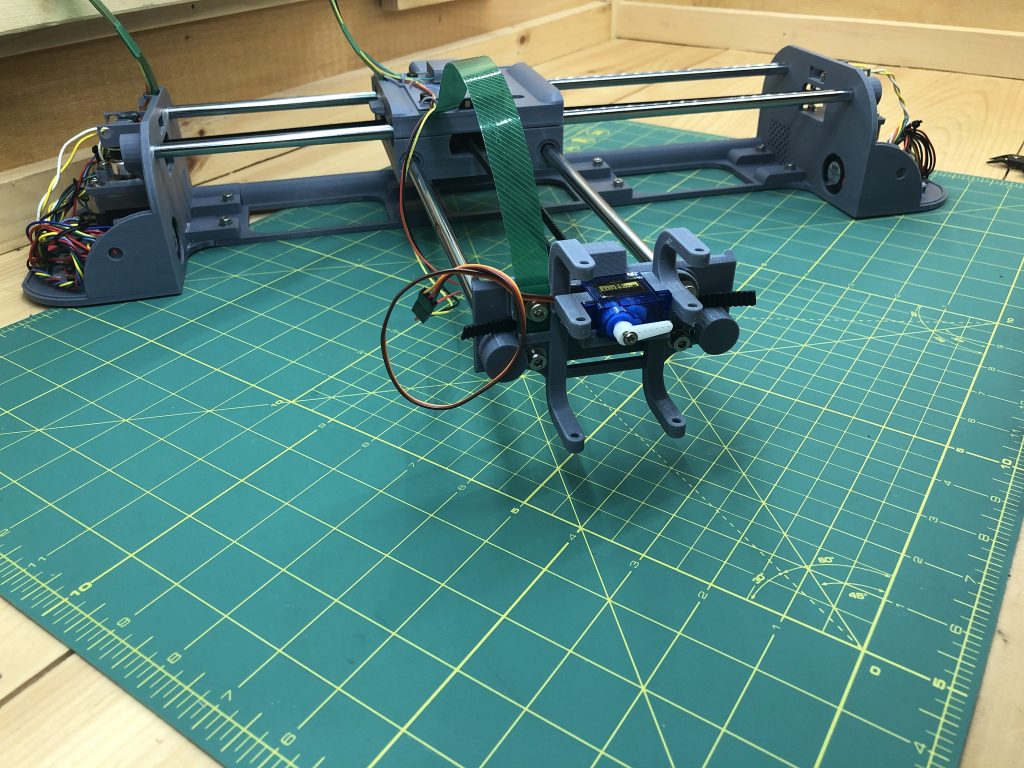

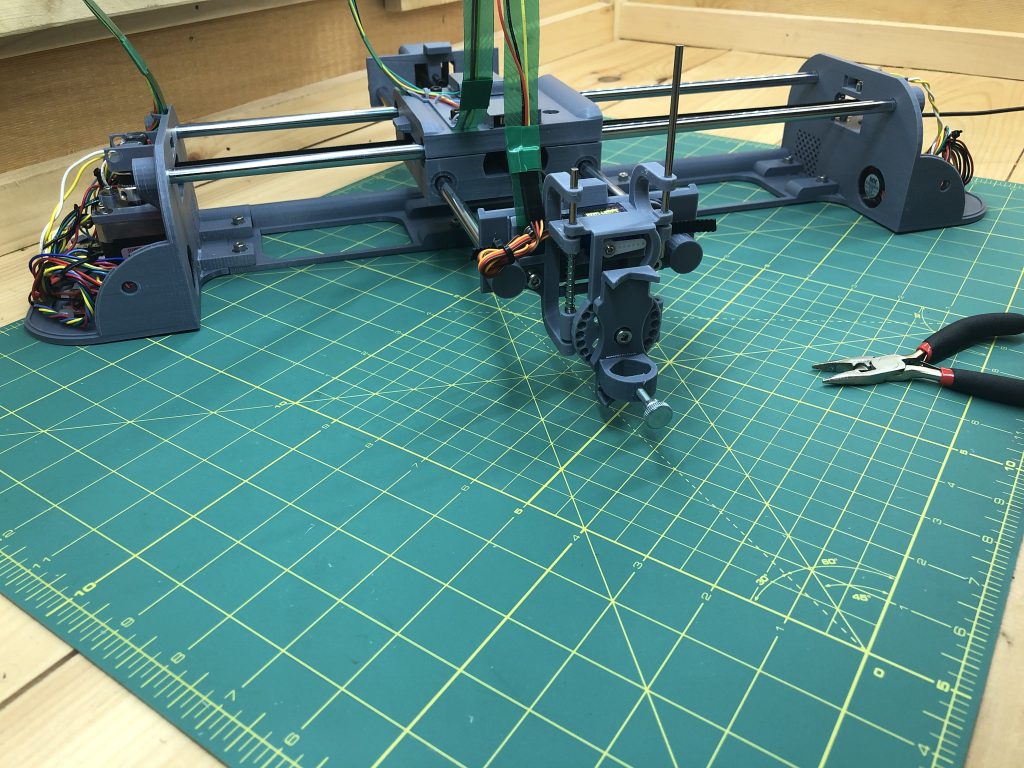

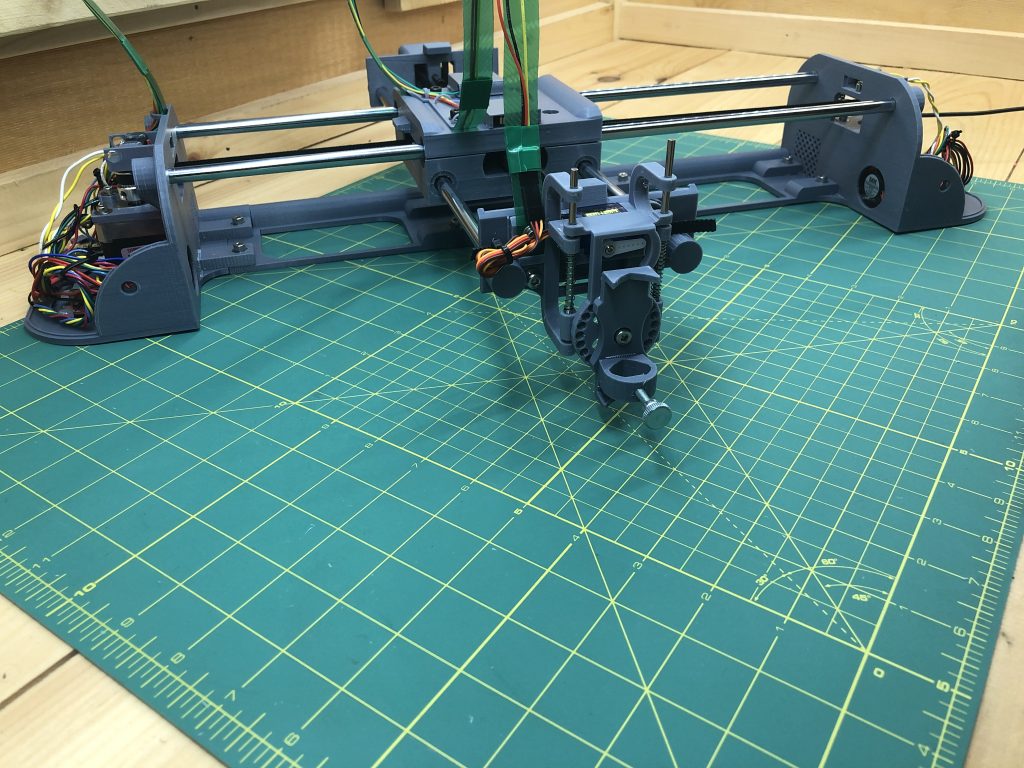

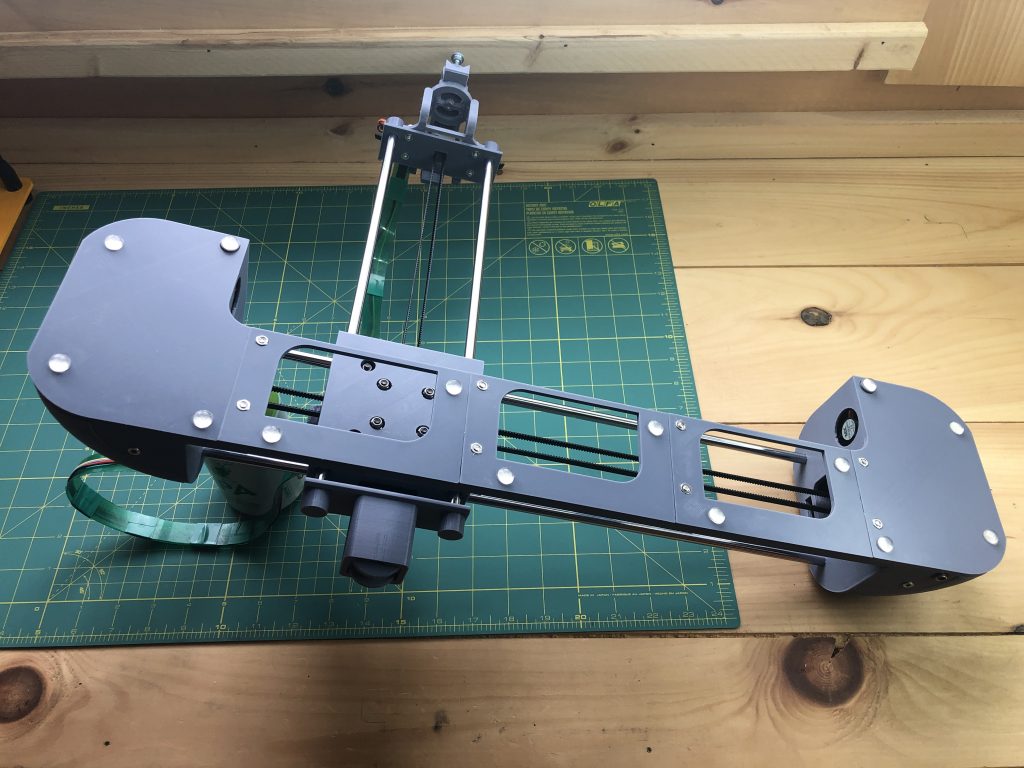

Finished Build

Downloads

Build Instructions

Parts to gather

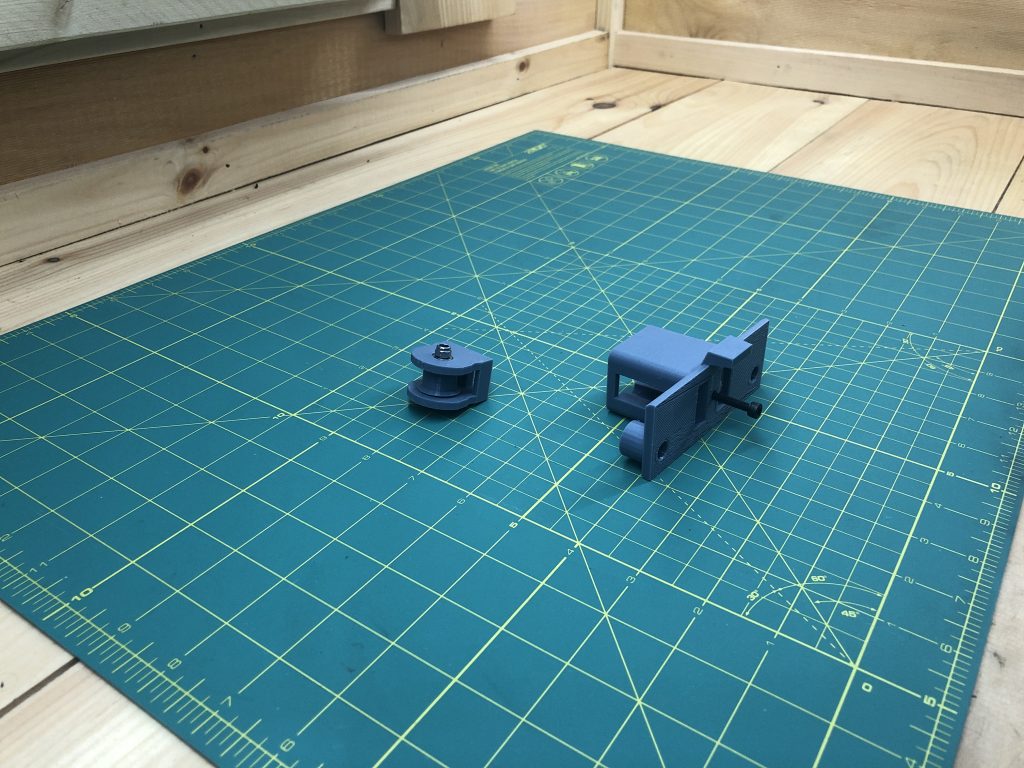

3D printed

Grab all the STL parts from here. Each part file has a name finishing with the quantity you need print of it.

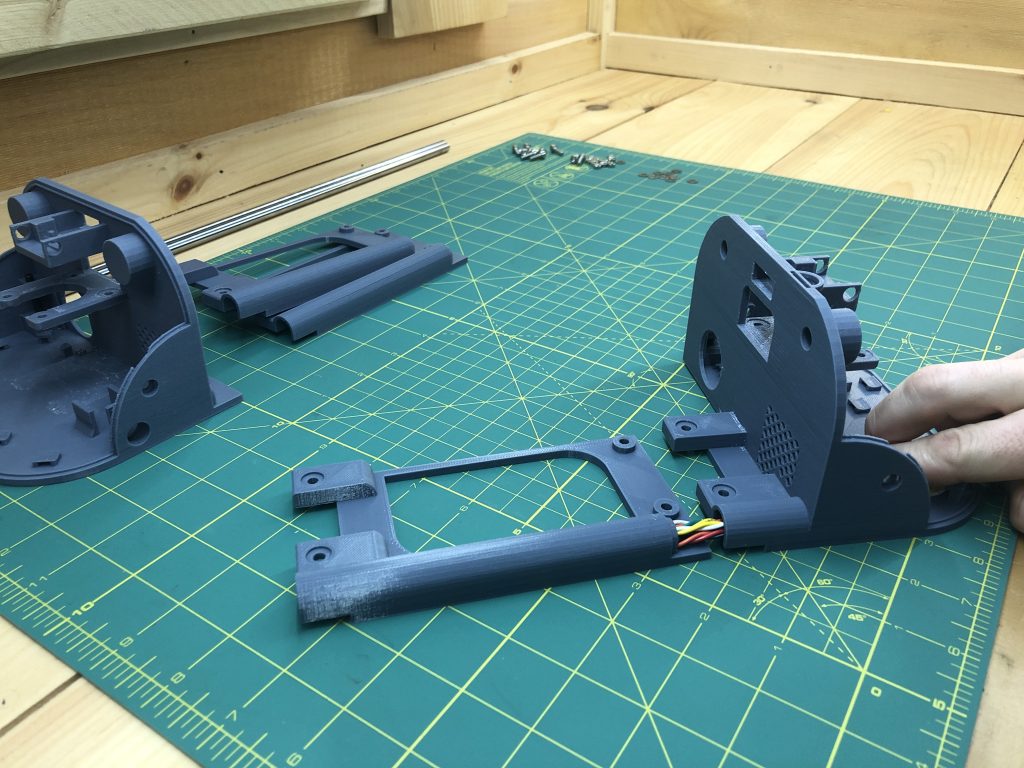

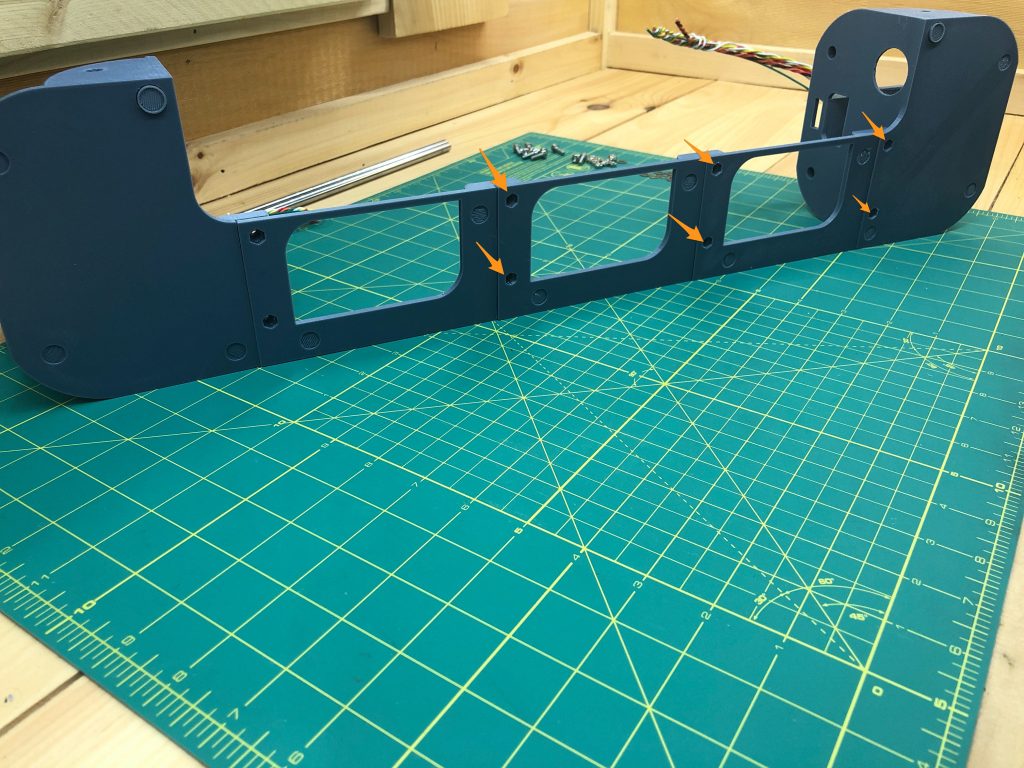

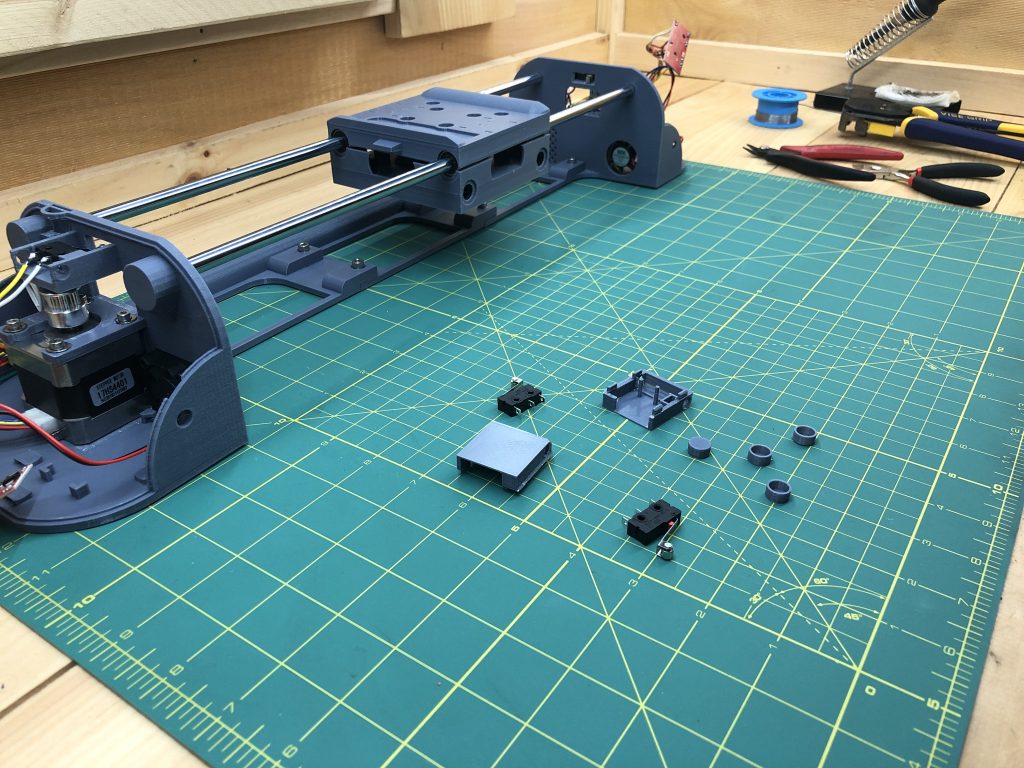

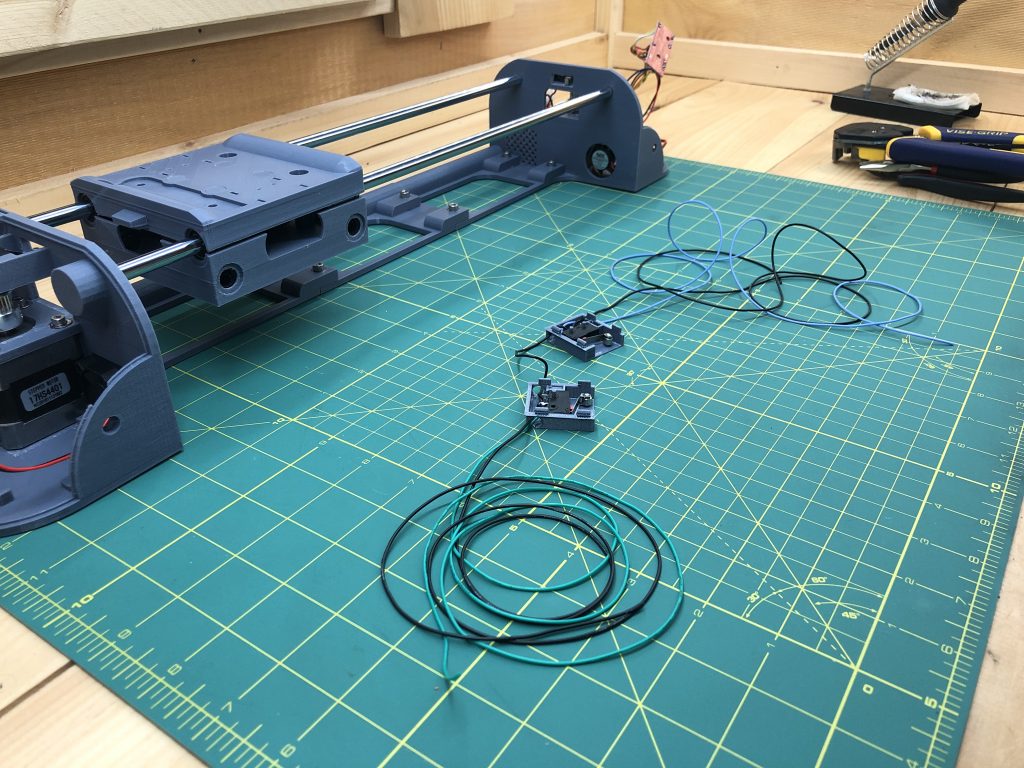

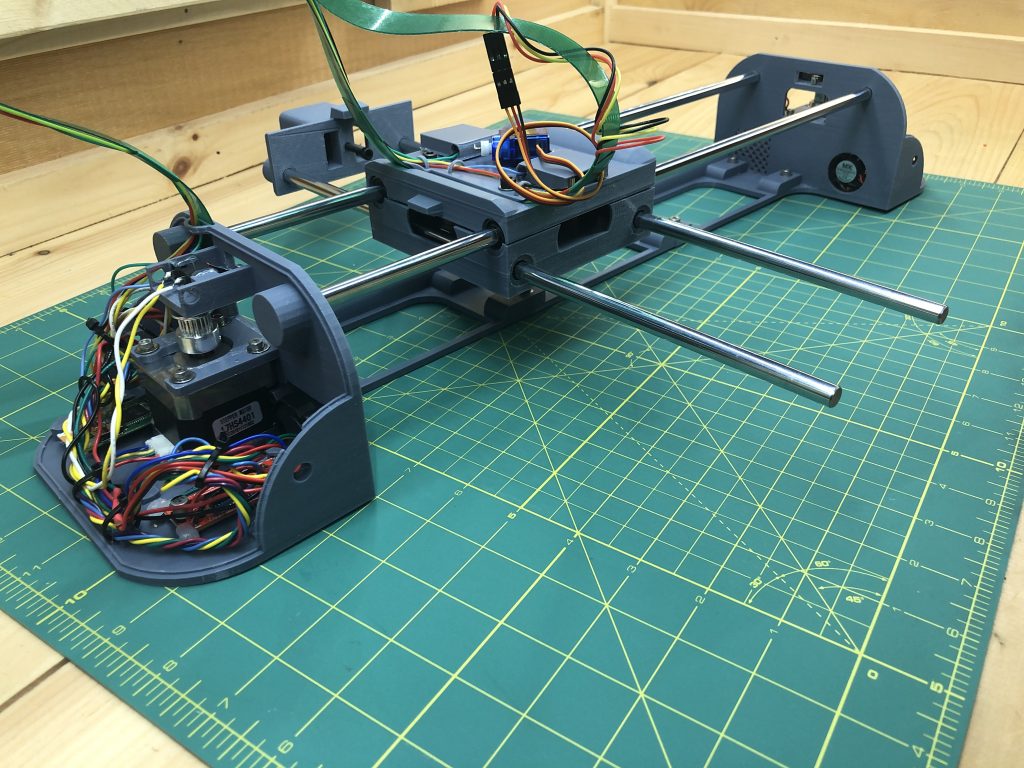

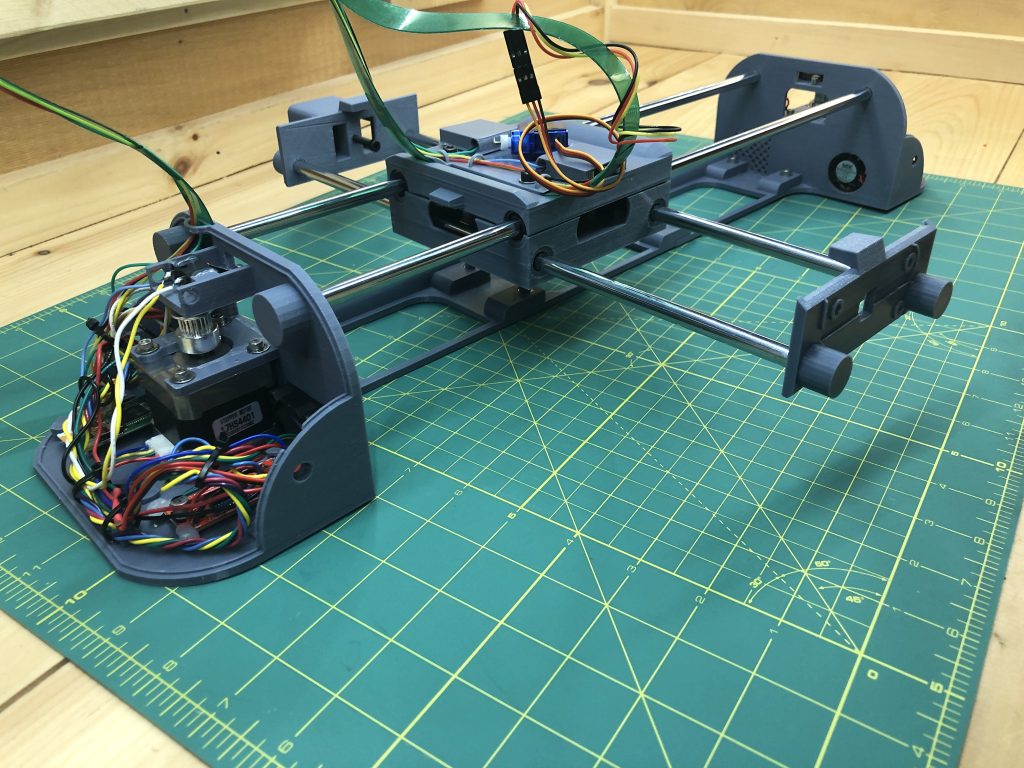

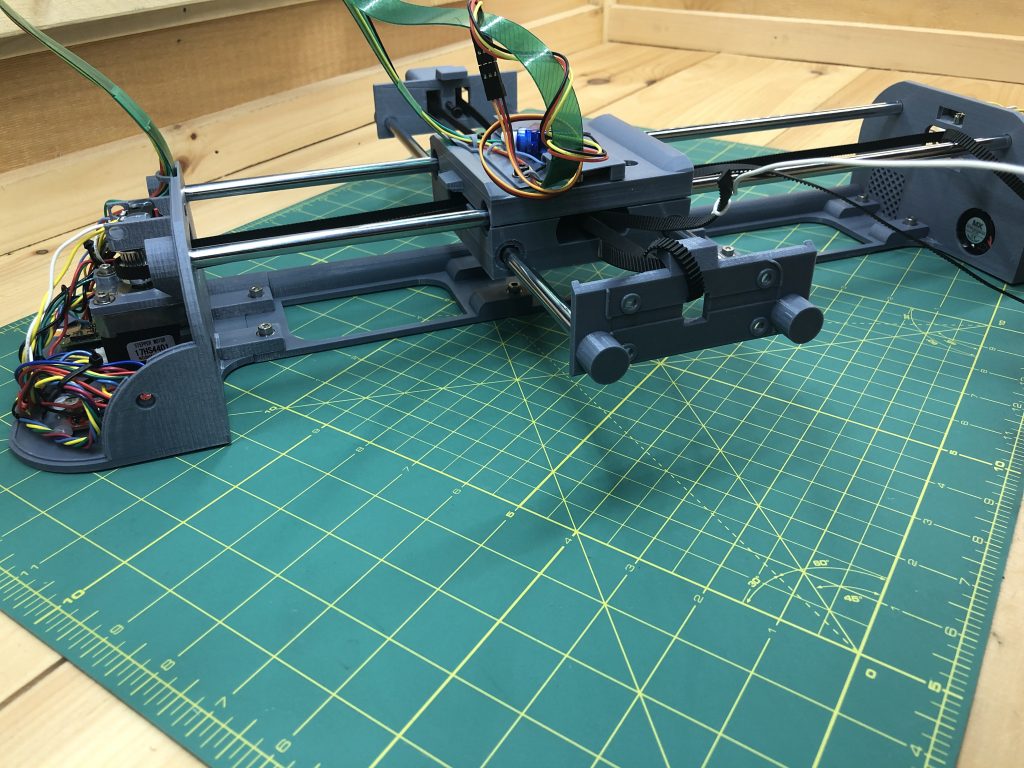

When all are printed, you’ll have this:

Acquired

Tools to have

- soldering iron

- glue gun (or sugru mouldable glue)

- allen wrench set

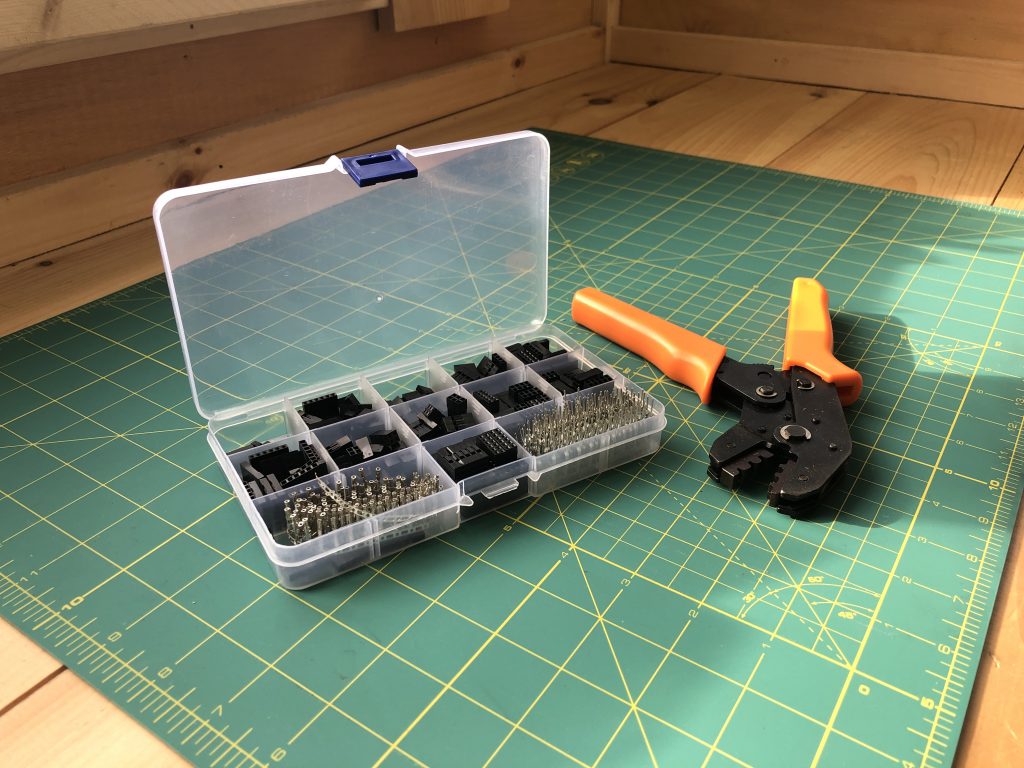

- dupont wire connection kit (possibly optional)

Consumables

wiring

Household items

bendable plastic you can cut

click pens to steal their perfectly sized springs

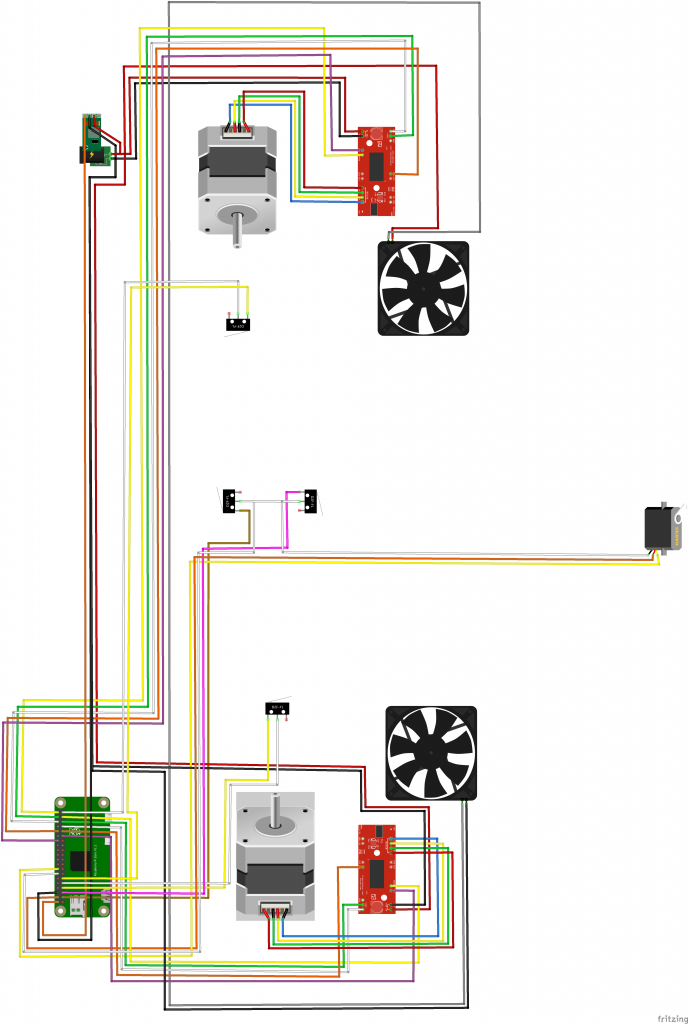

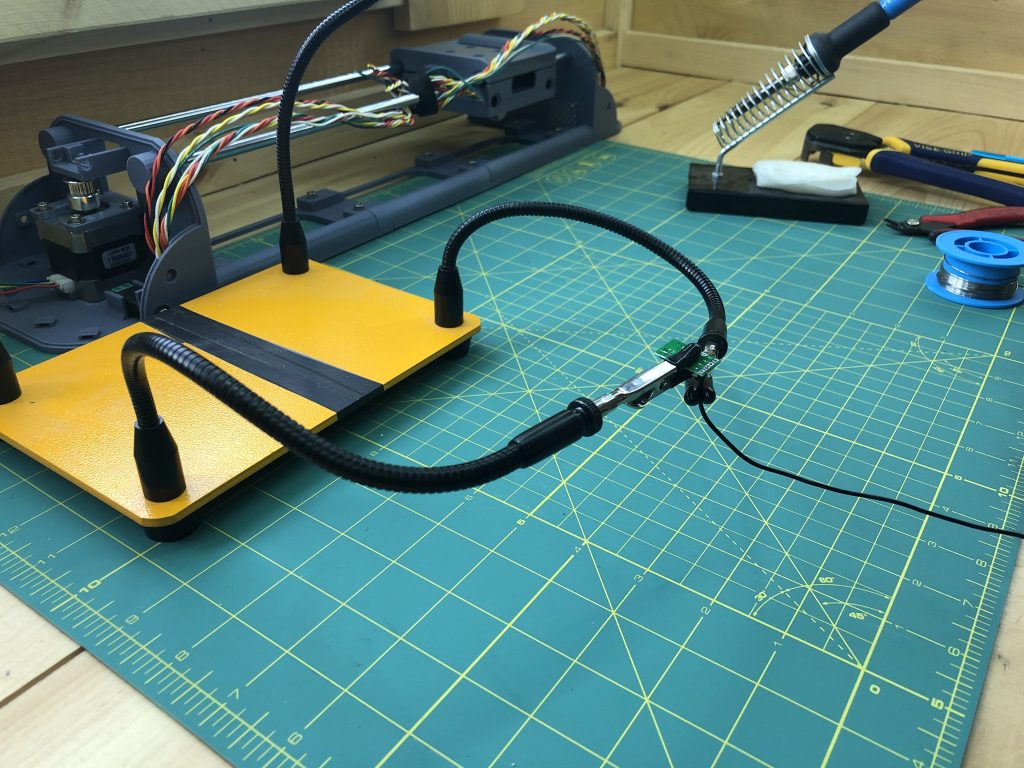

Circuit

Here is a full representation of the final circuit where we’re going to build. We’ll take it step by step, this is only for reference.

Click image for full size

Step by Step

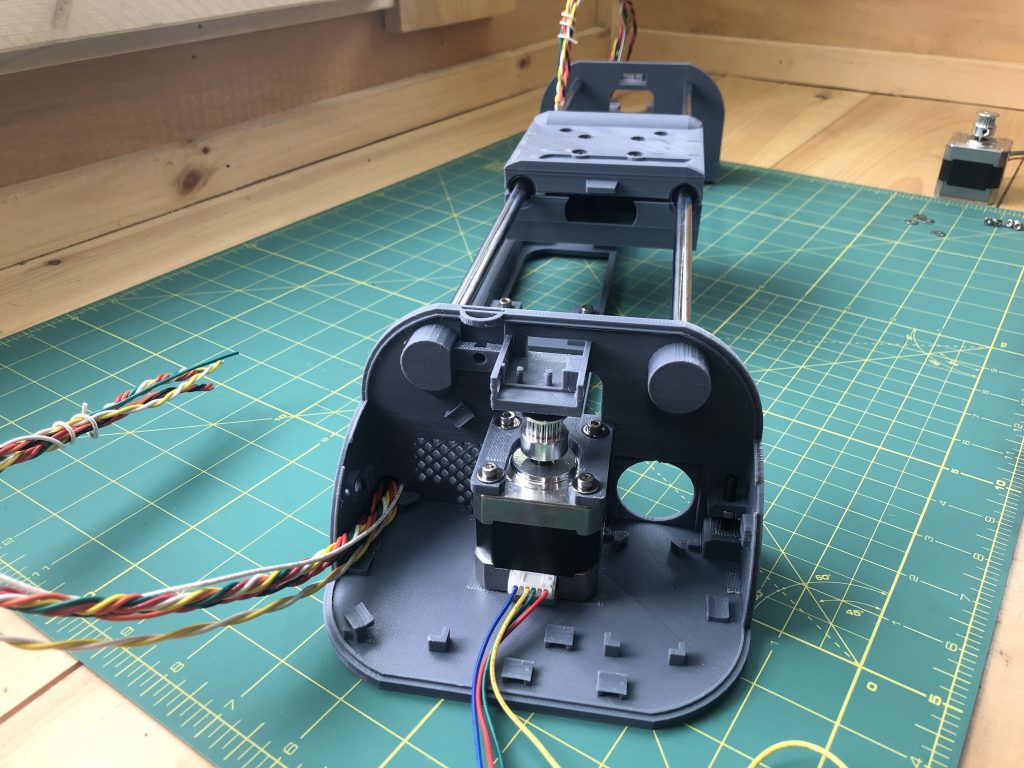

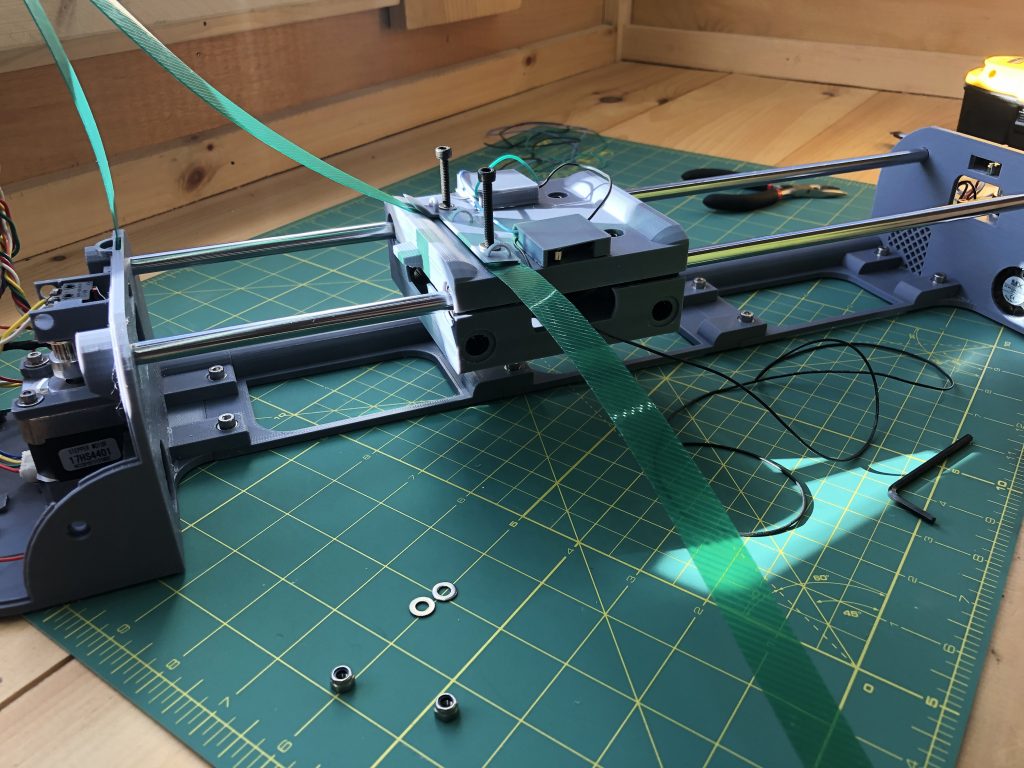

1. Gondola

Hardware:

4 M4x35 hex screw

4 M4 lock nut

8 washers

10 bearings

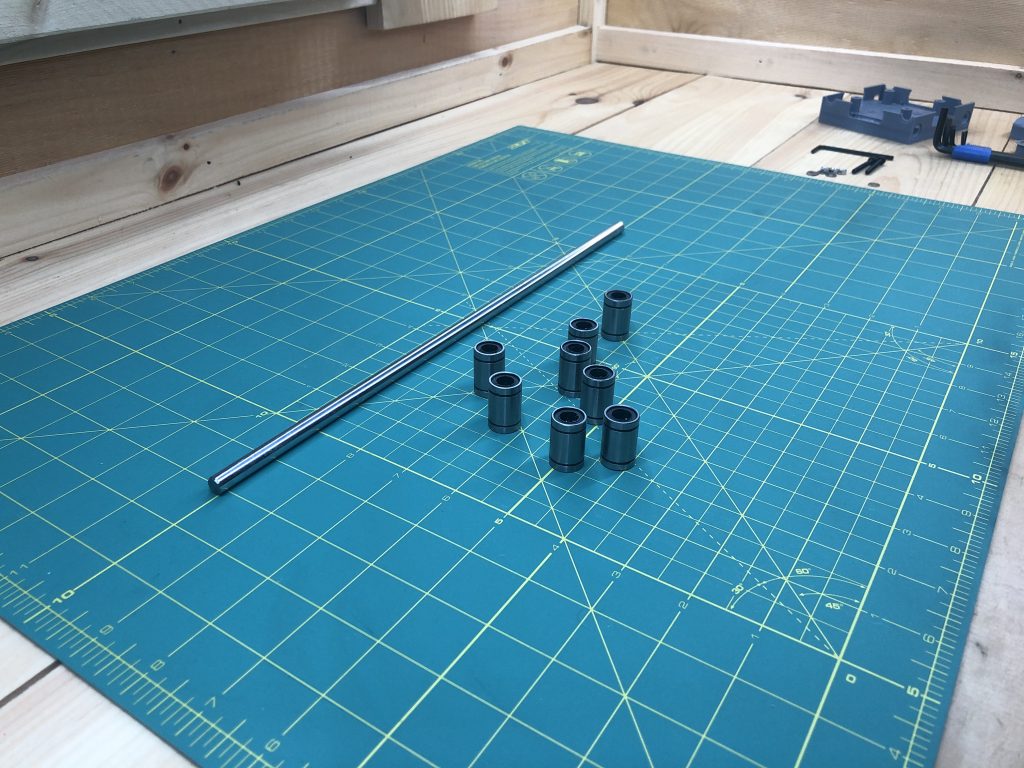

8 LM8UU linear bearings

3D Parts:

gondola_bottom_x1

gondola_top_x1

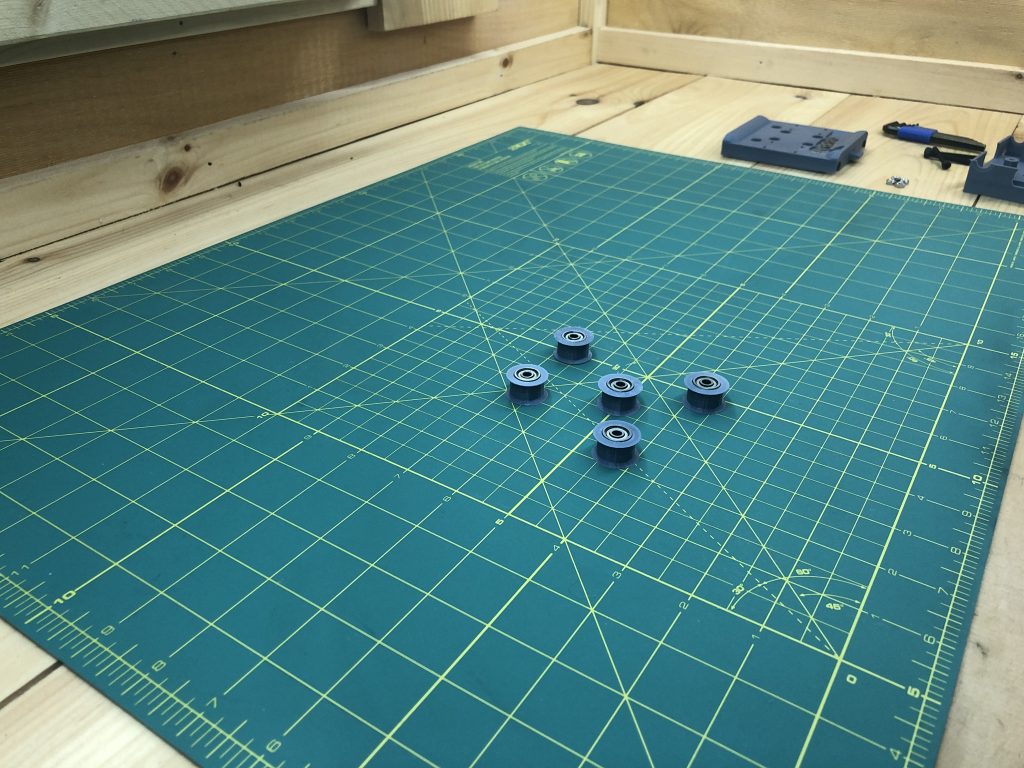

belt_roller_x5

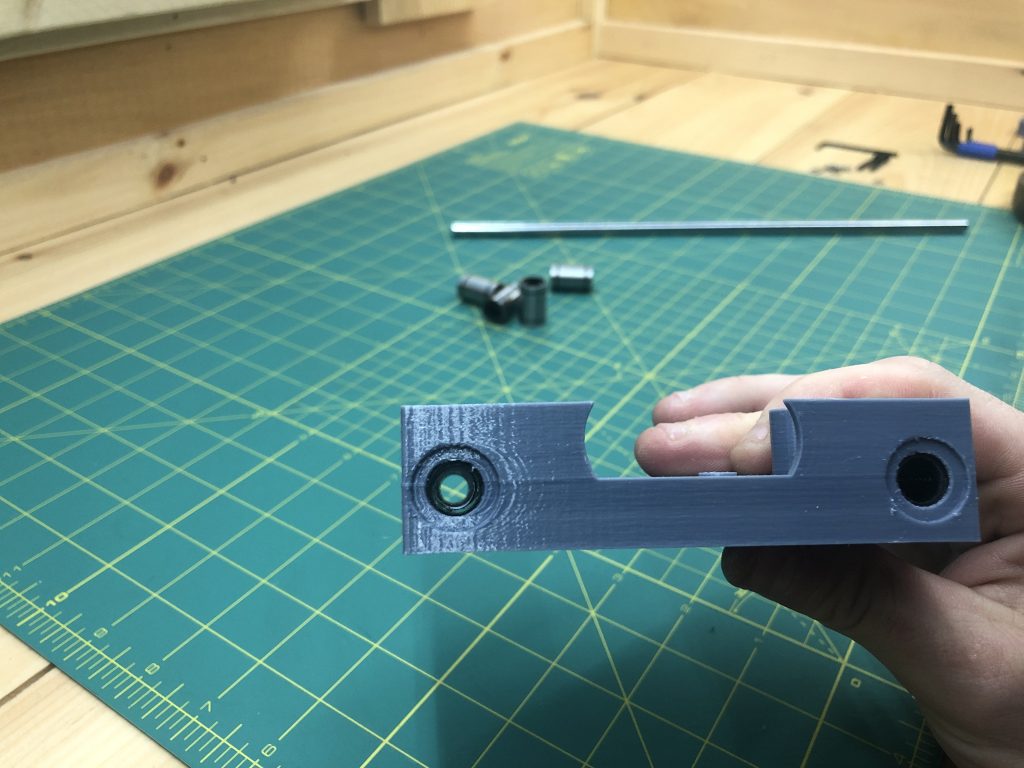

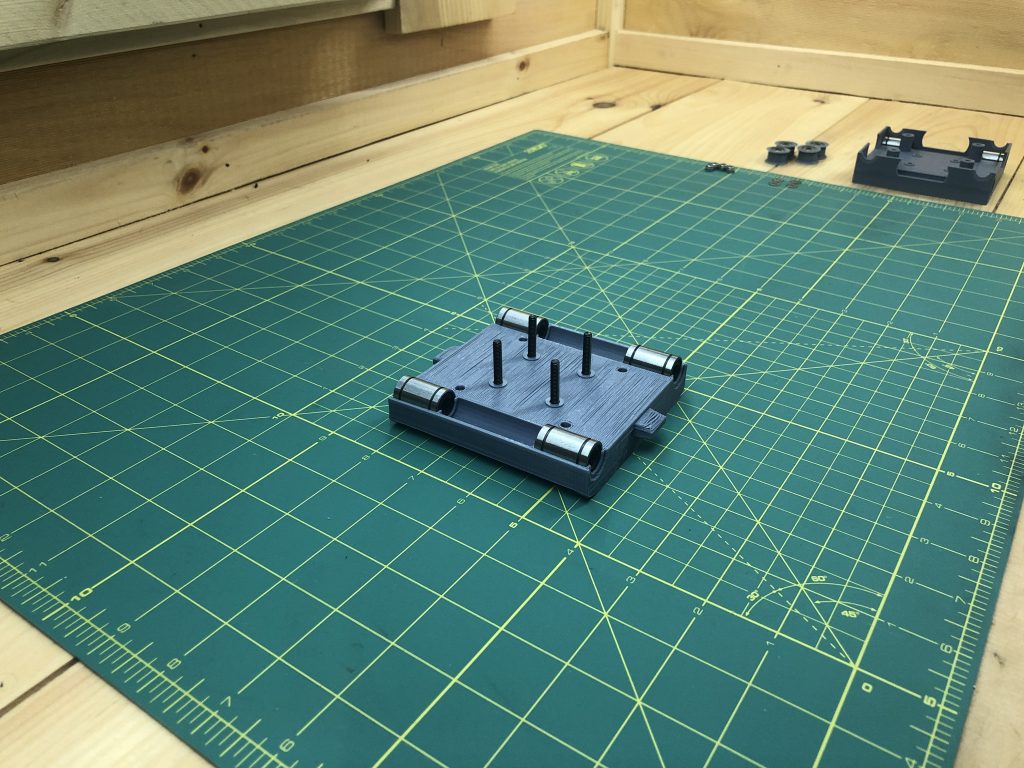

For each belt roller, gently hammer in 2 bearings, one on each side. Use a piece of wood or something to shield the bearings from the hammer.

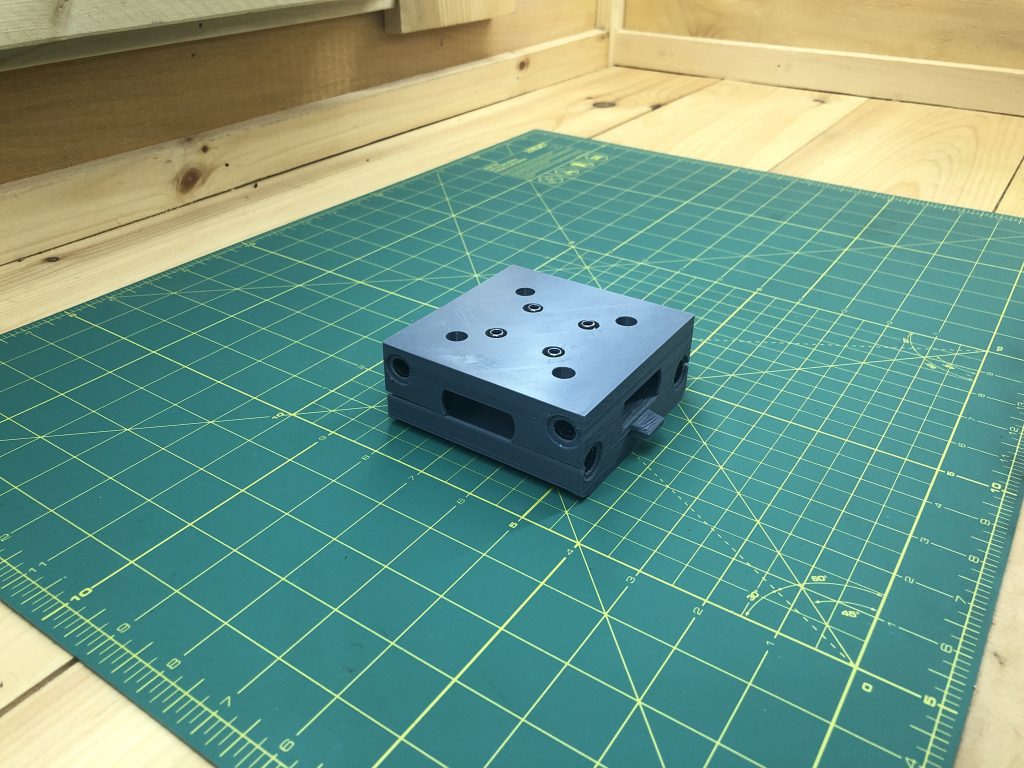

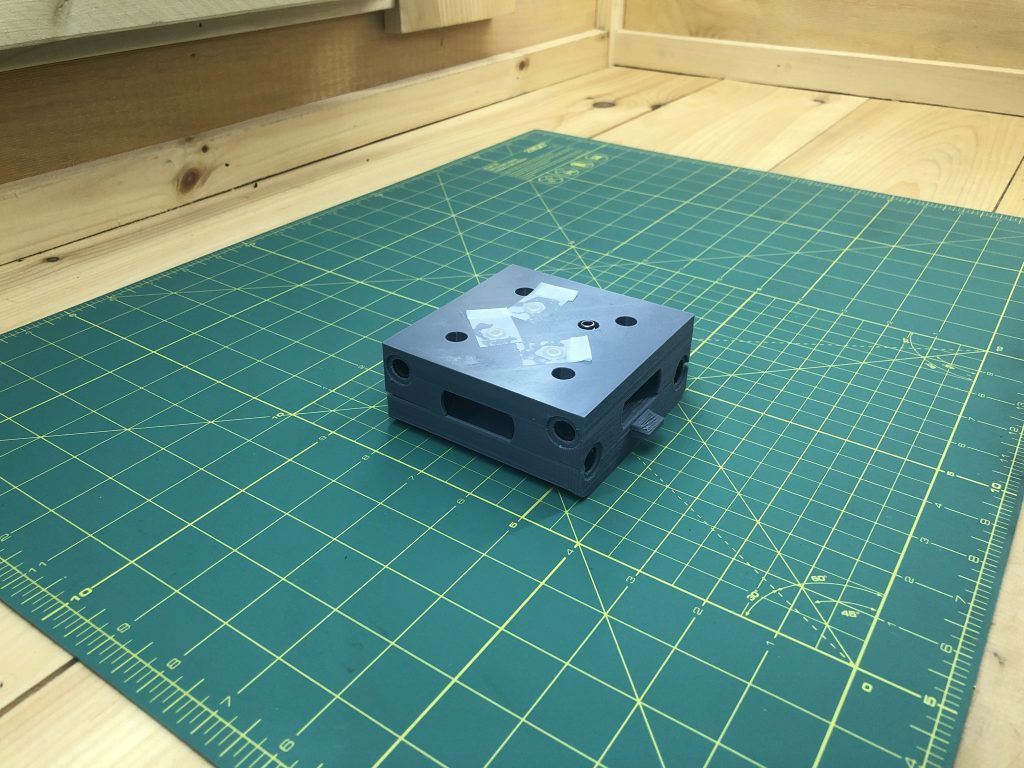

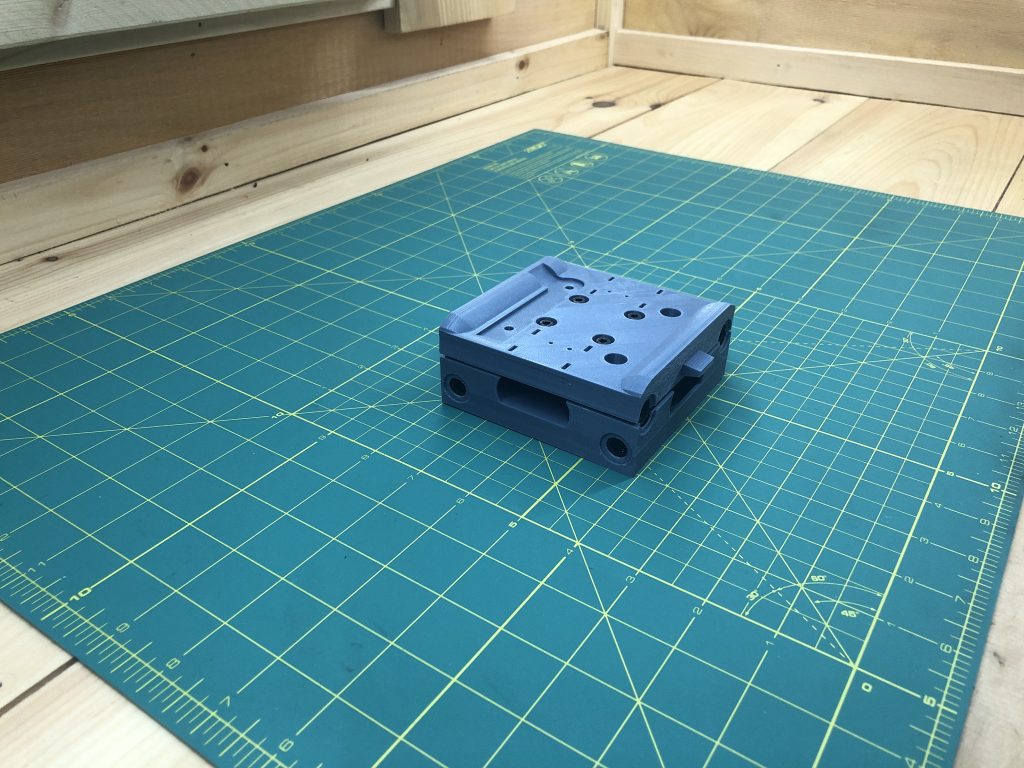

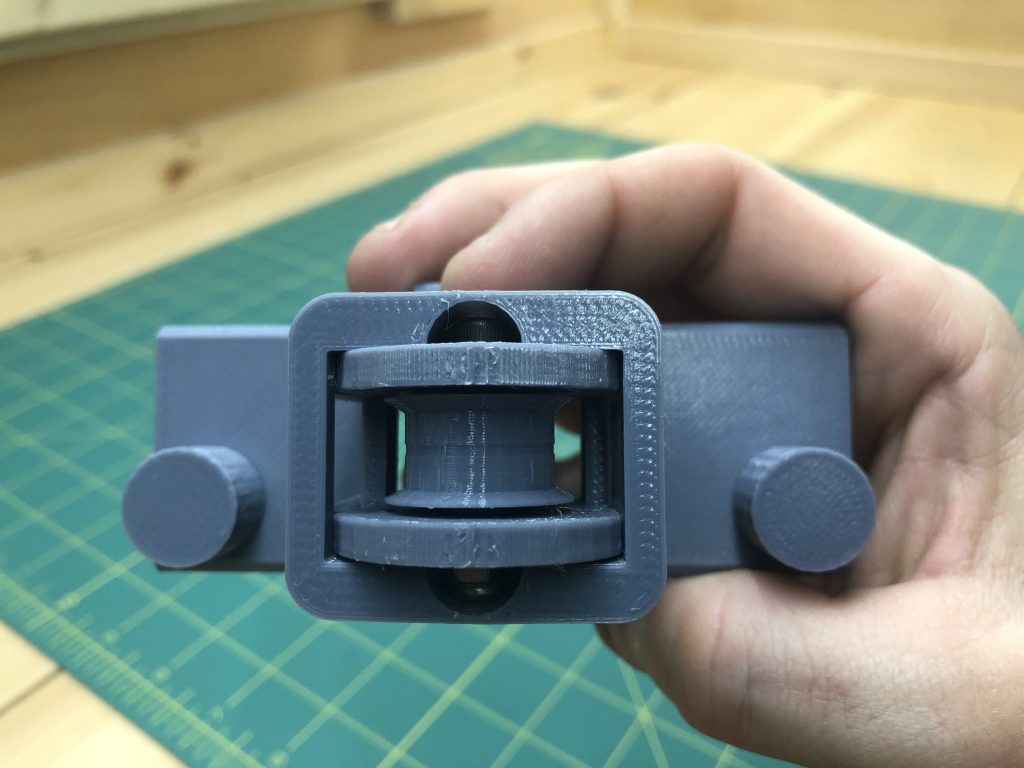

Your belt rollers will look like this when you’re done:

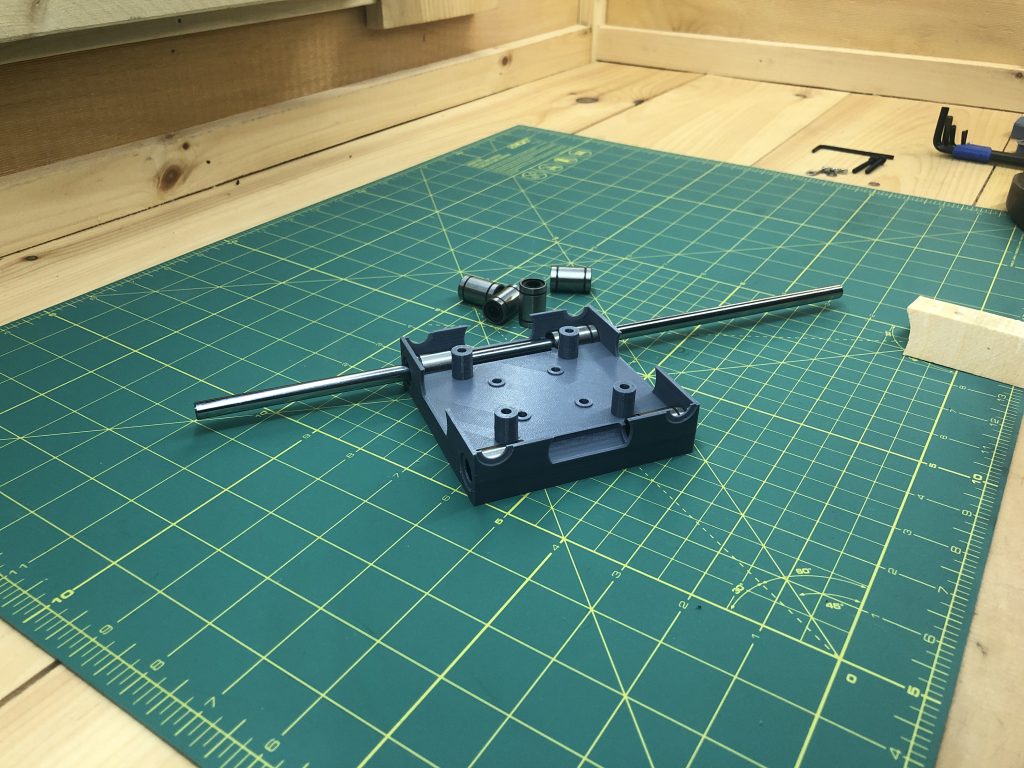

Grab the LM8UU linear bearings, also grab one of the linear rods simply to test them before you commit them to your build.

You don’t want a bad linear bearing so it’s a good idea to run them along the rod and make sure they move smoothly. You’ll know immediately if one of them sticks, throw it away and get another one.

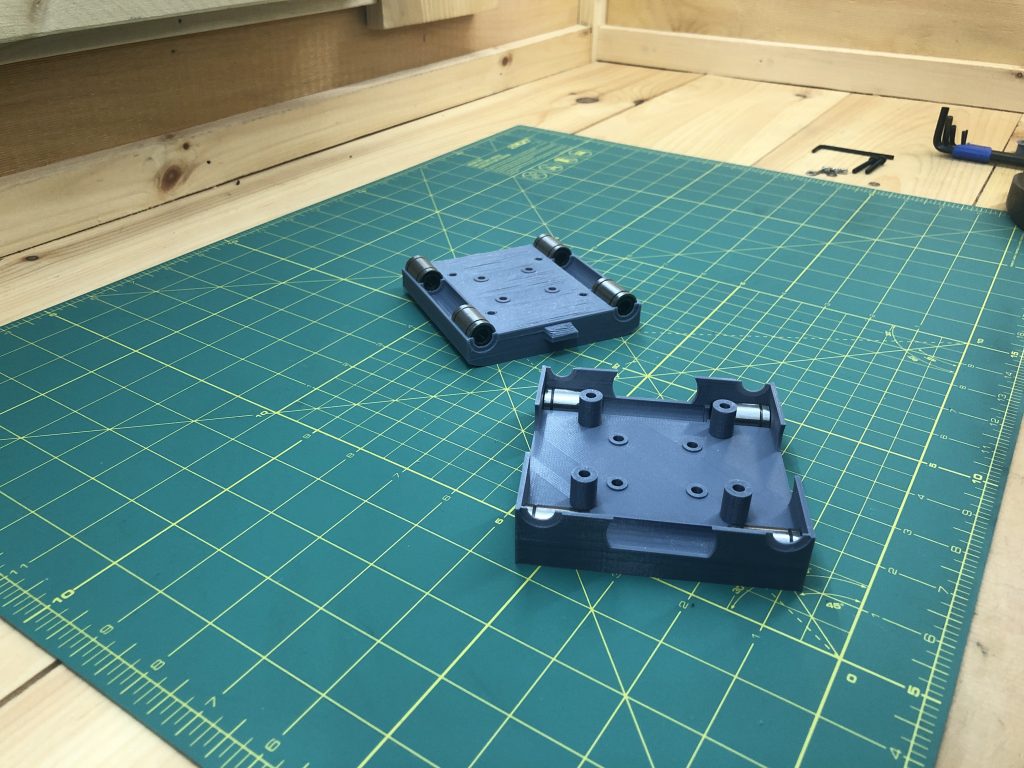

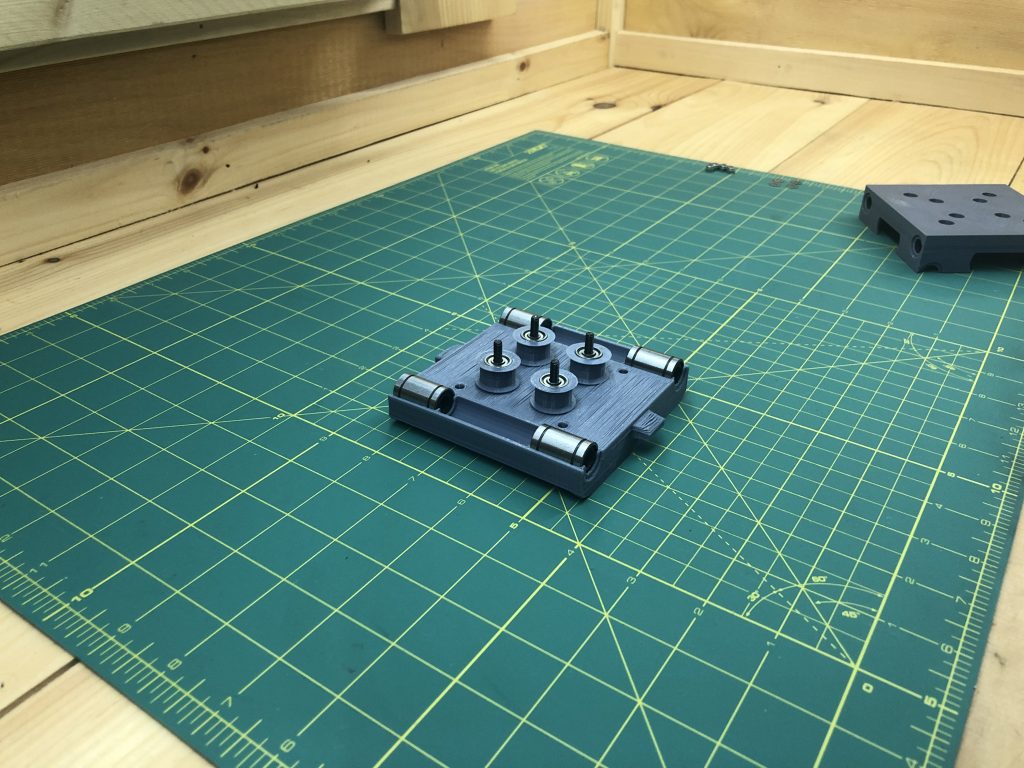

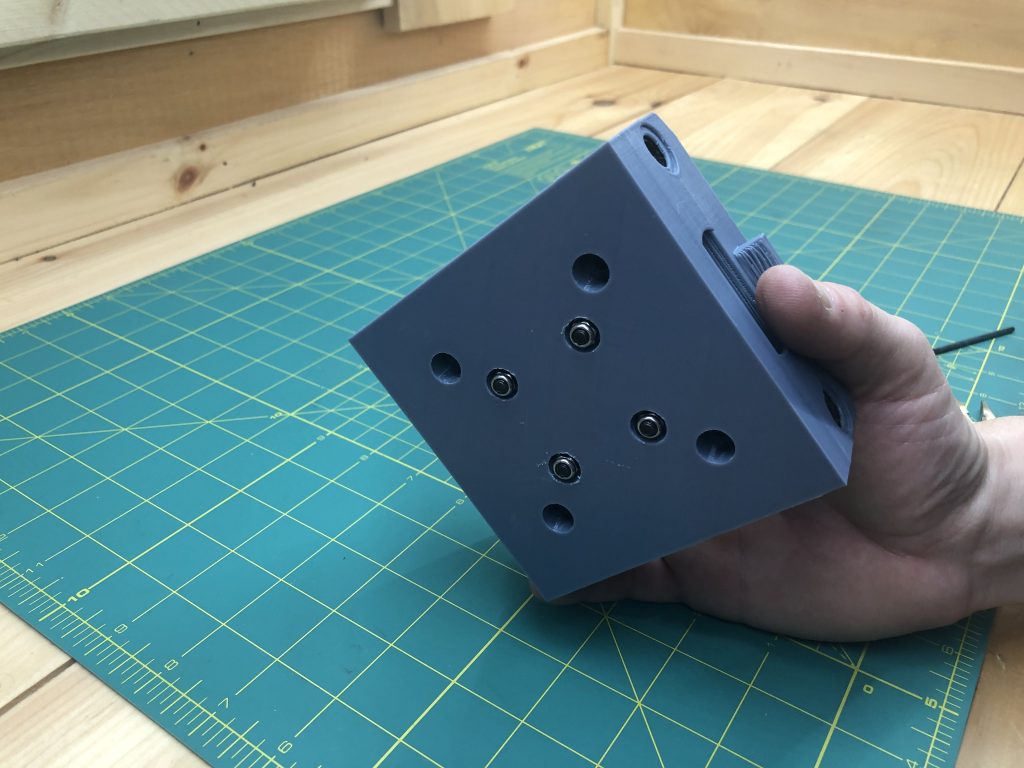

Now that you know all your linear bearings are up to par, insert them in each corner of gondola_bottom and gondola_top. You can pressure fit them.

And of course, gentle hammering can help, be really careful not to damage anything in the part.

When you’re done, you’ll have a nice line of sight from one end to the other.

You can use the rod once more to make sure it runs smoothly through both bearings in a line.

When you are done, both the top and bottom parts of your gondola will each have 4 linear bearings in their corners.

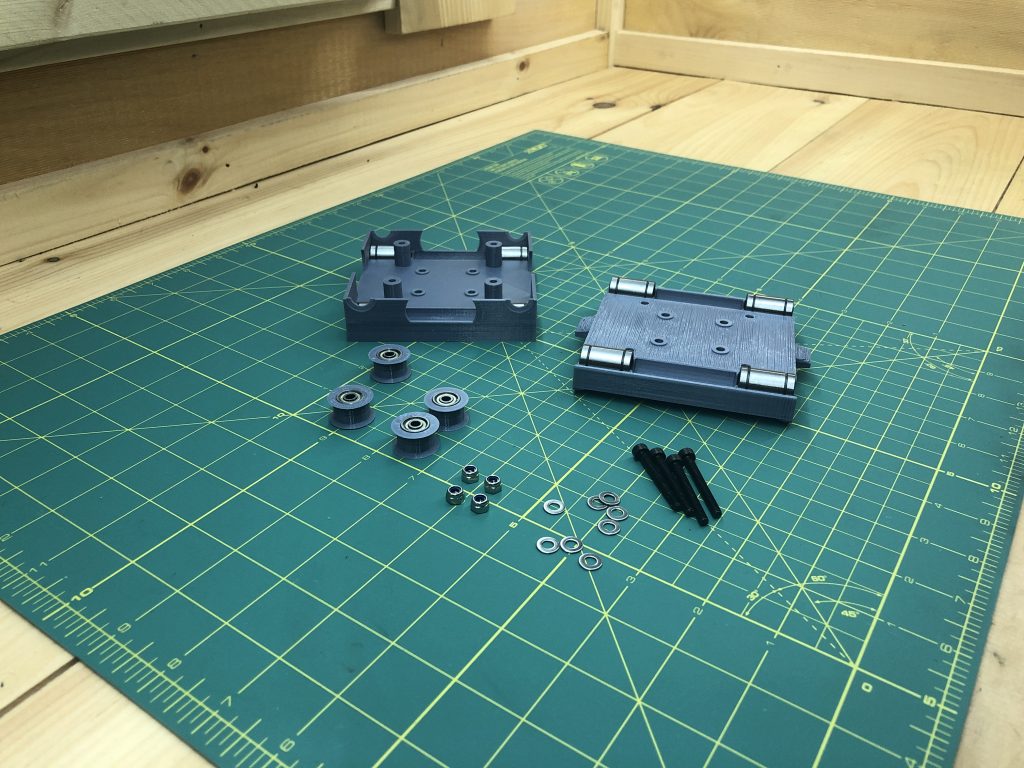

Get your belt rollers and the rest of the hardware.

Put the 4 M4x35 hex screws through the top part with washers.

Place it upside down on your work surface.

Add 4 belt rollers (we’ll use the 5th later on).

Place the bottom part on top.

Add 4 washers and lock nuts into the innermost holes.

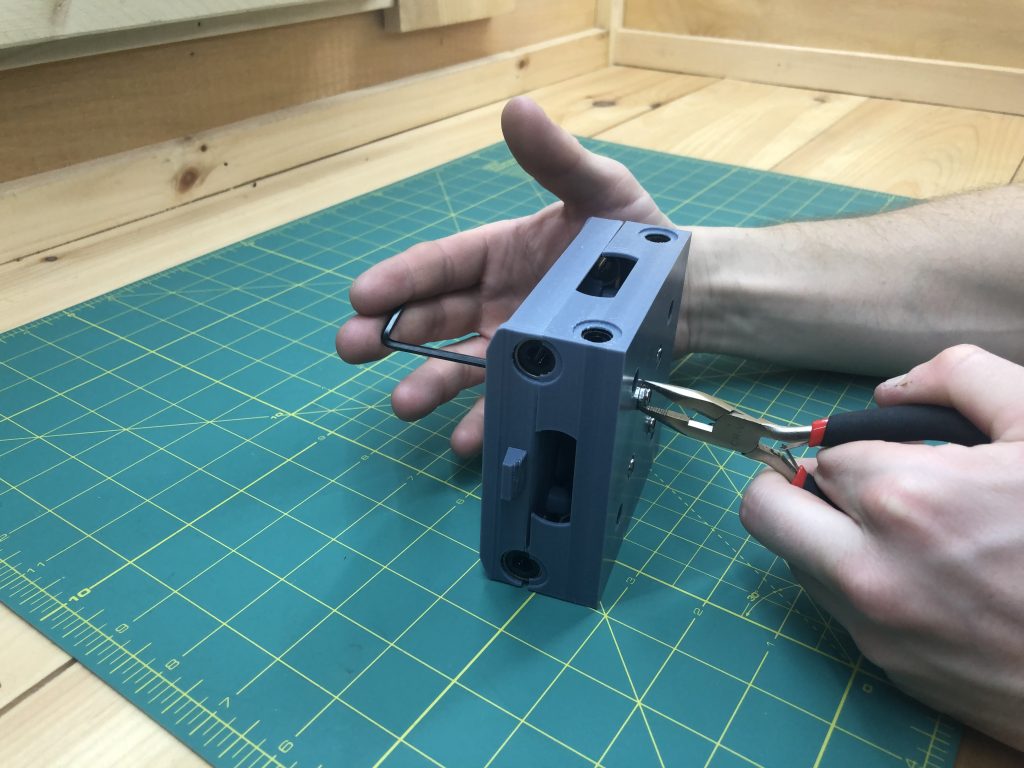

Because we’re going to be handling all this, I like to tape over the 3 nuts I’m not working on so they don’t keep falling. I remove a piece of tape when I’m ready to work on another nut.

Tighten each nut, the operation is a bit tricky, not only because you’re working with a different tool on both side, but also because lock nuts are very tight. Do not tighten the nuts firmly, the screw and its nut should float just a bit. These screws do not hold the gondola together, they only provide an axle for the belt rollers.

Make sure that each belt roller rolls freely inside.

It’ll look this this when you’re done.

3. Back Assembly Belt Roller

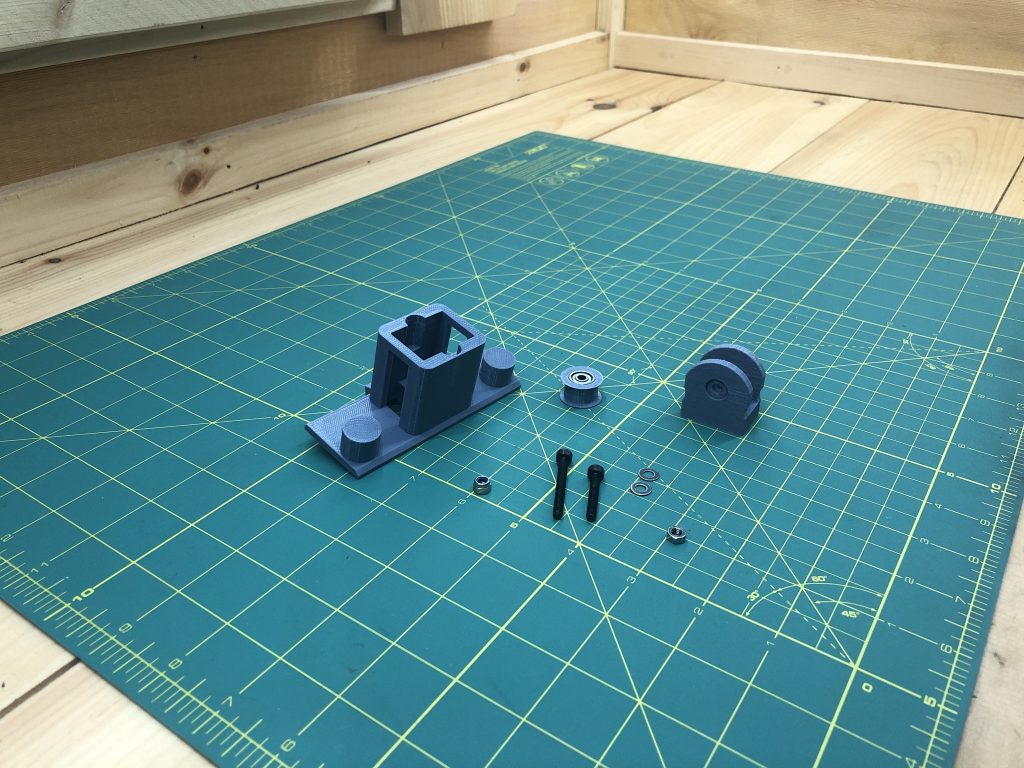

Hardware:

1 M4x35 hex screw

1 M4x25 hex screw

1 M4 lock nut

1 M4 nut

2 washers

3D Parts:

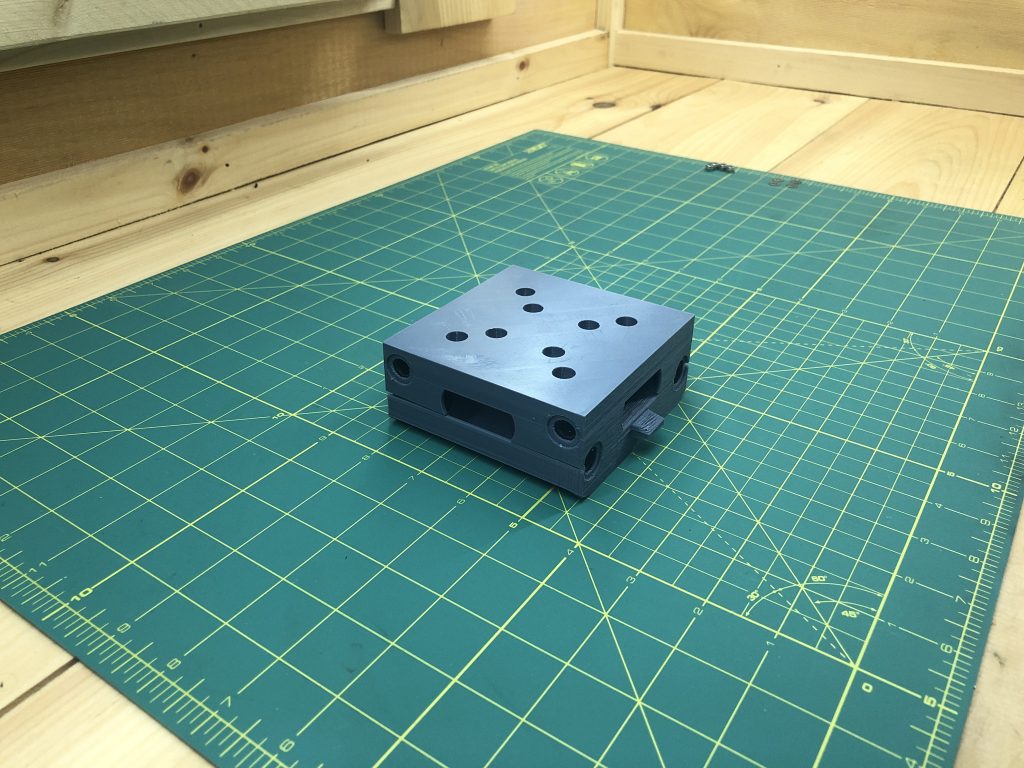

back_assembly_x1

back_assembly_belt_tightener_x1

We’ll also use the 5th belt roller you made while building the gondola. While we’re doing belt rollers, it make sense to do this part :).

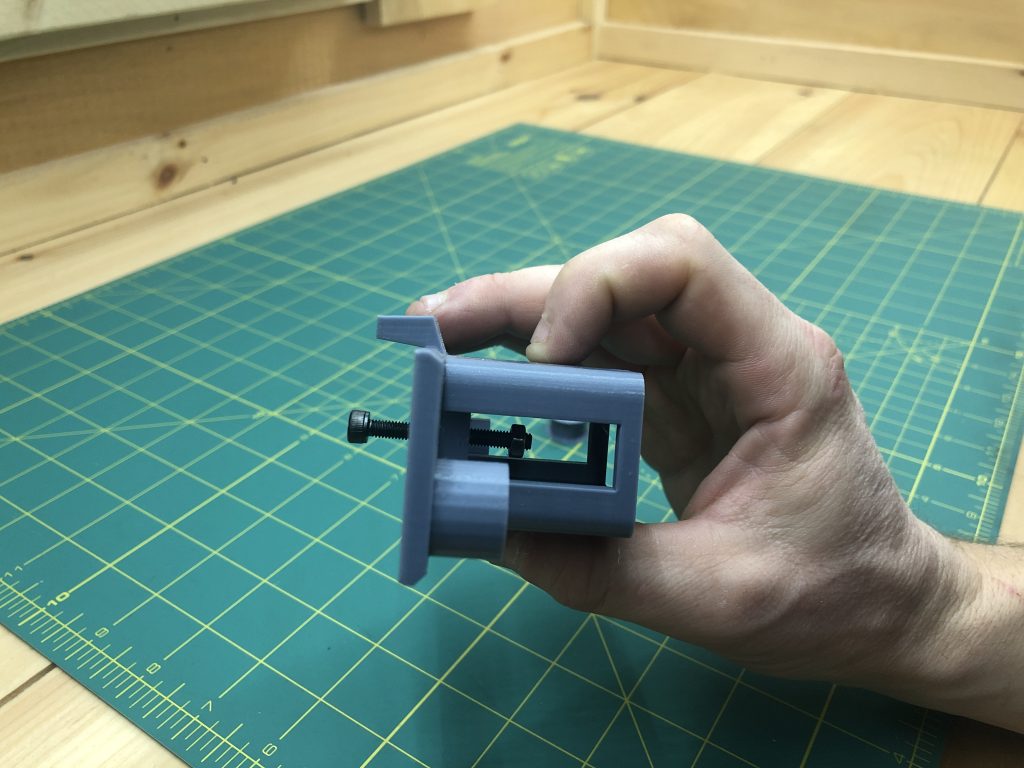

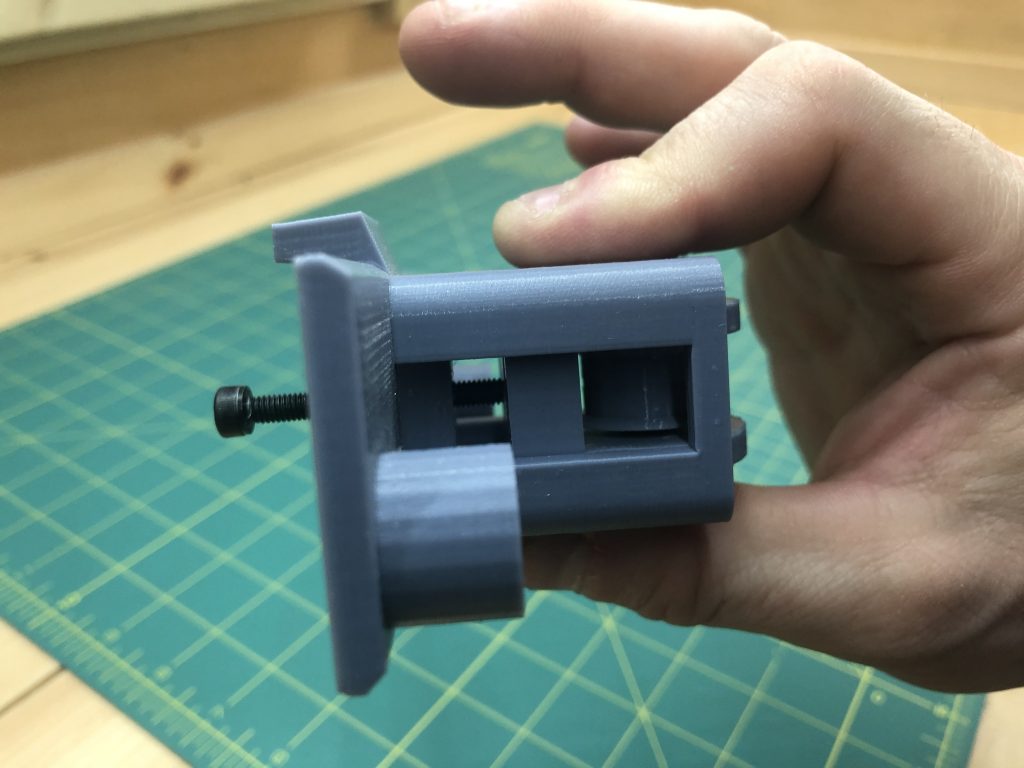

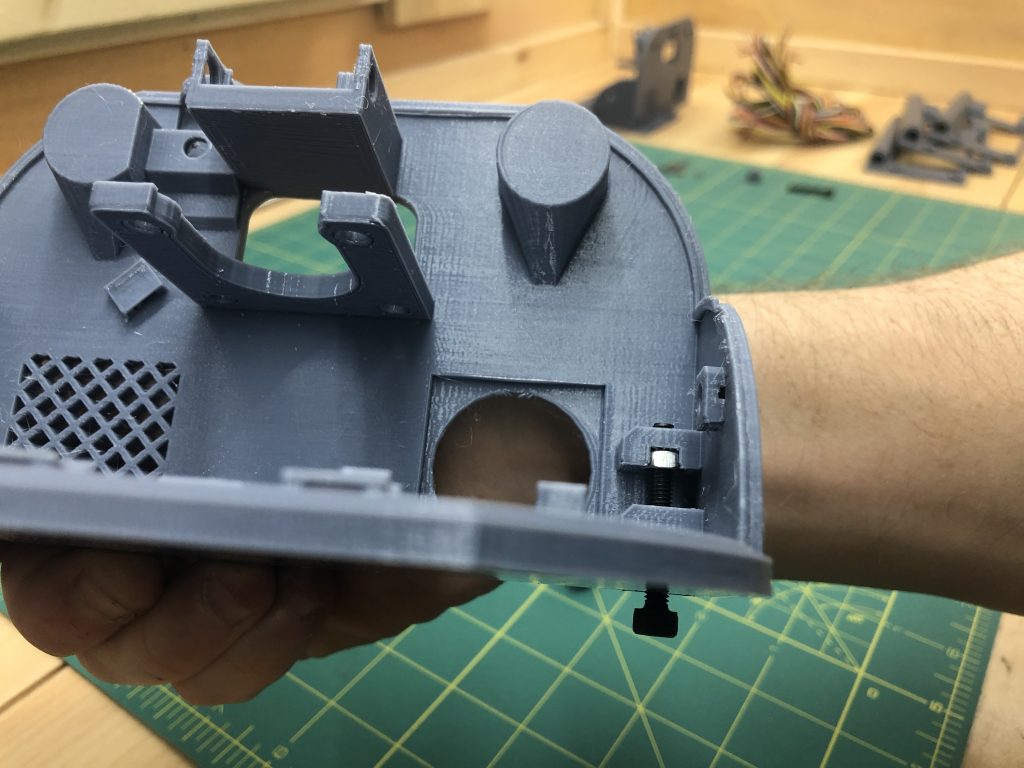

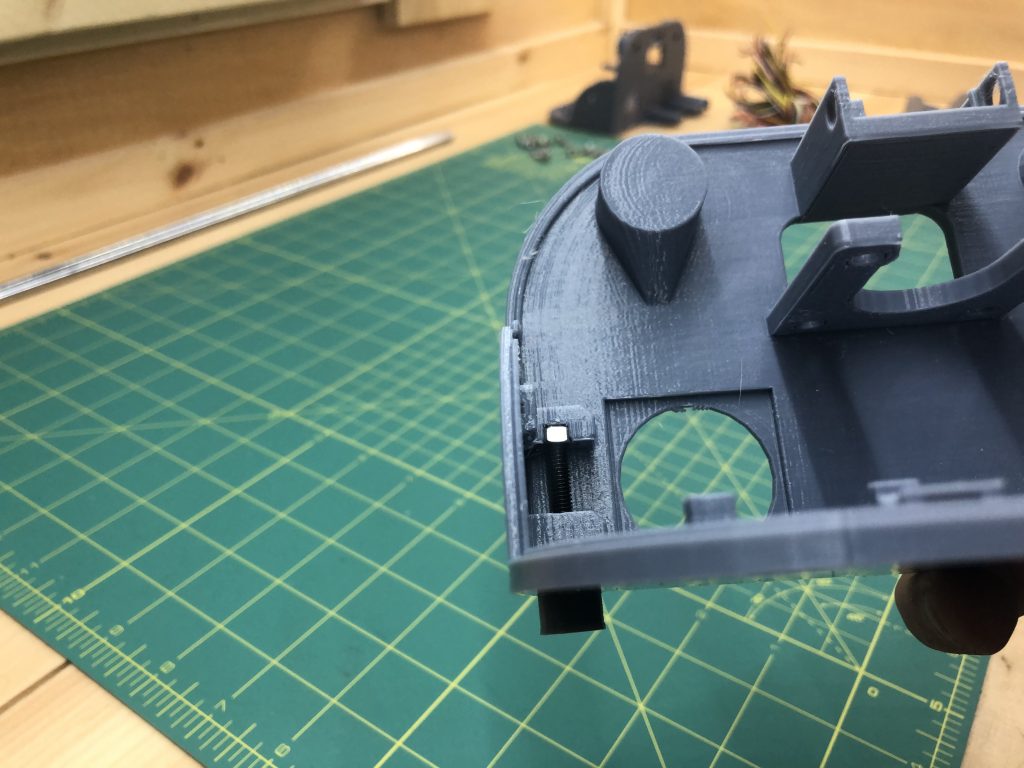

Grab the back assembly, the M4x35 hex screw and the M4 nut. Insert the screw into the hole of the back assembly, screw in the nut on the other side. Then pull the screw to force the nut into its similarly shaped receptacle.

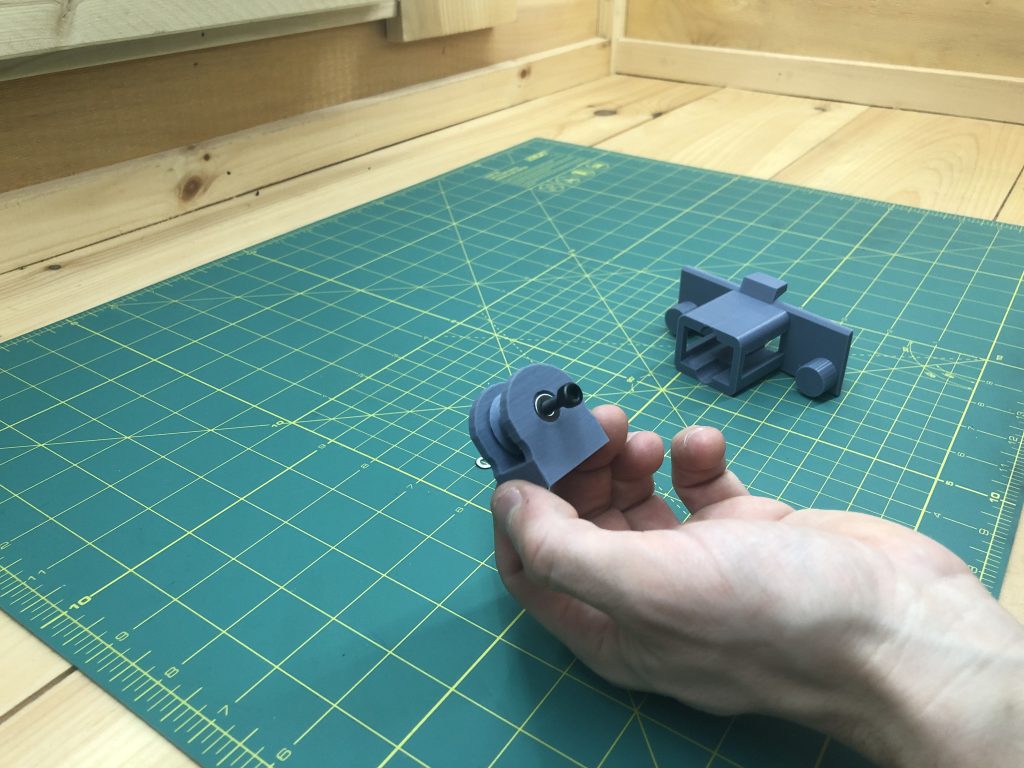

Grab the back_assembly_belt_tightener, put the M4x25 hex screw through it, lock nut on the other side and washers on both sides.

As with the gondola, do not overtighten the roller, this is only an axle. Make sure the belt rolls freely.

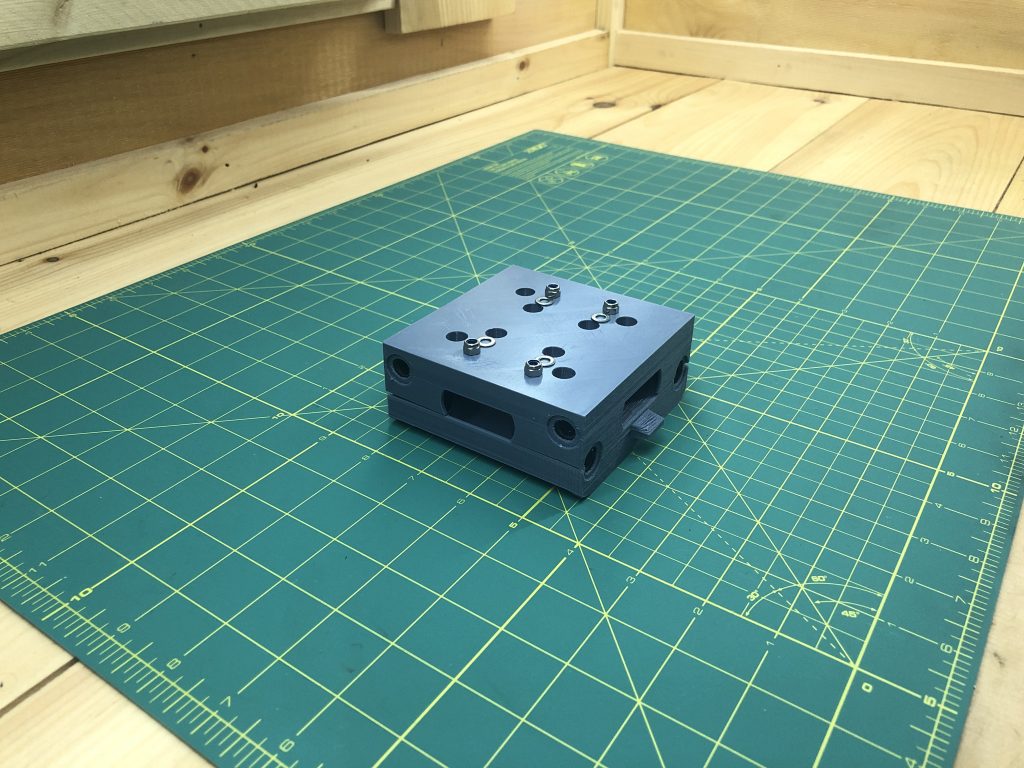

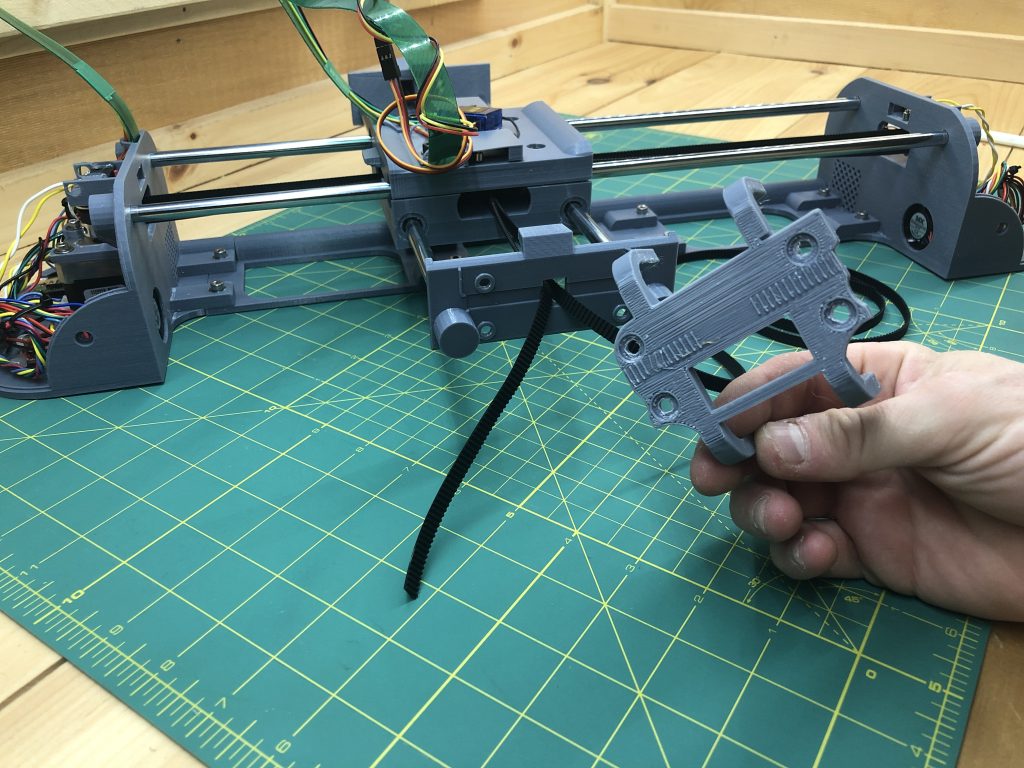

You’ve built both parts.

Now we put them together. One simply fits into the other as follows.

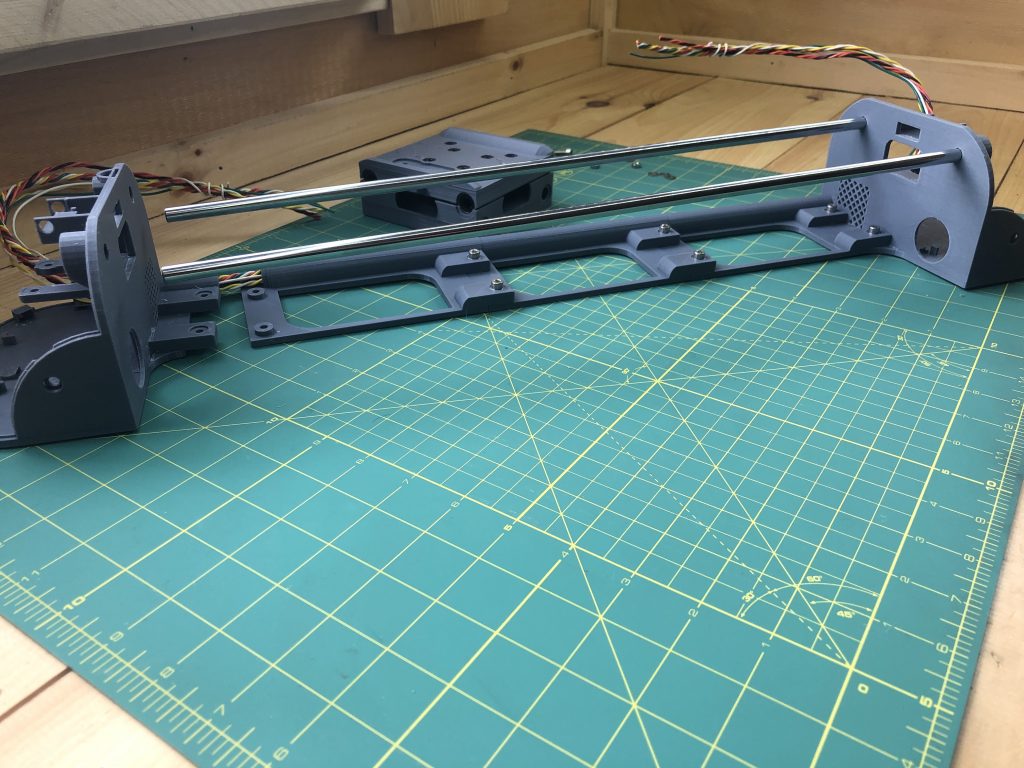

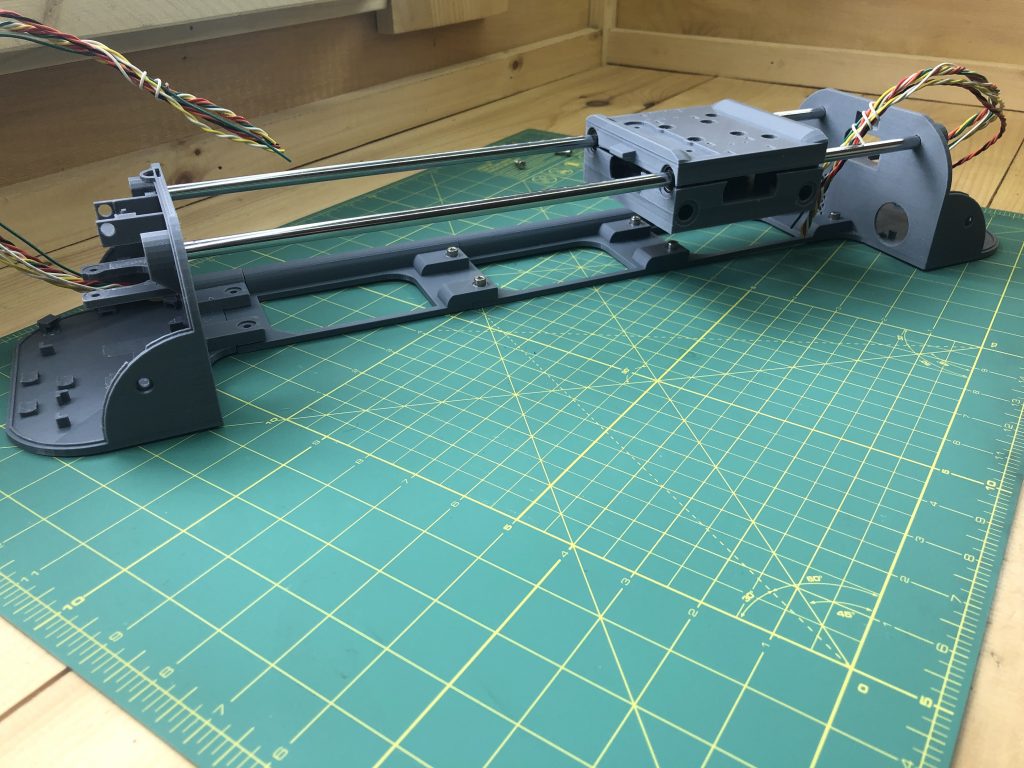

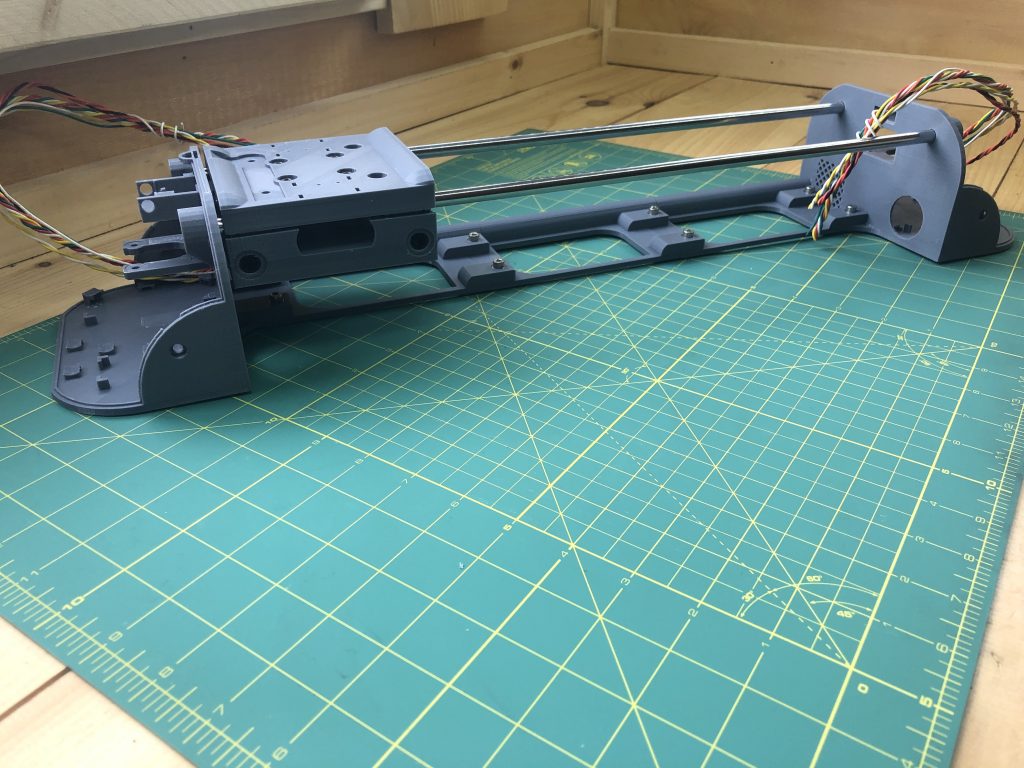

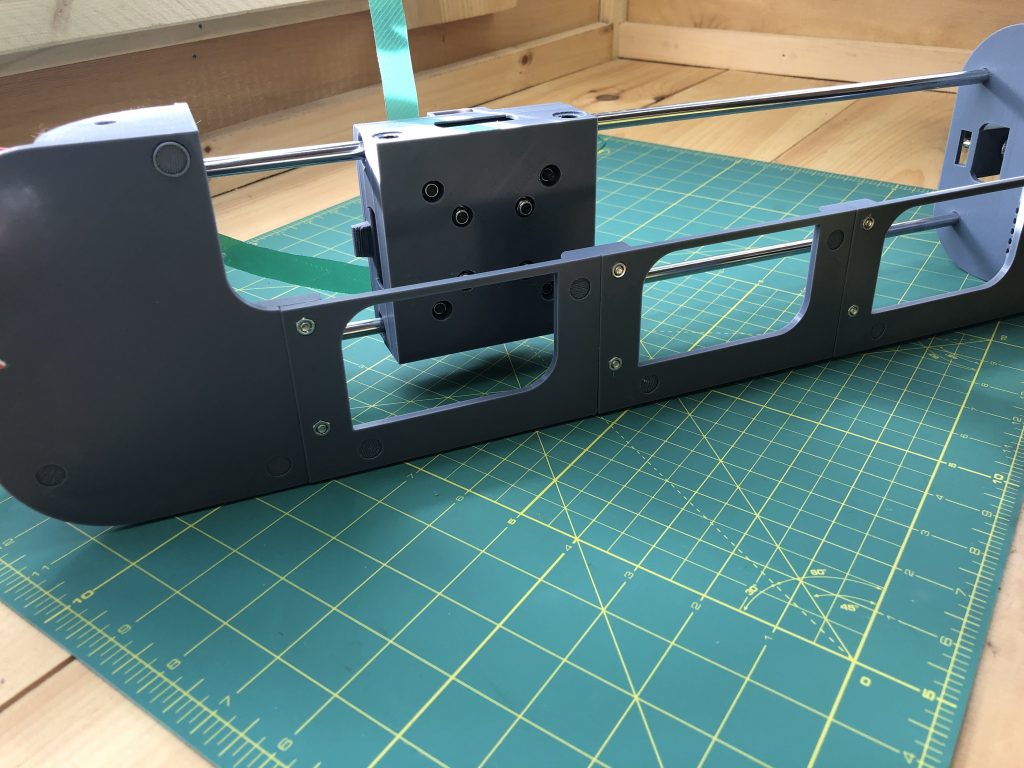

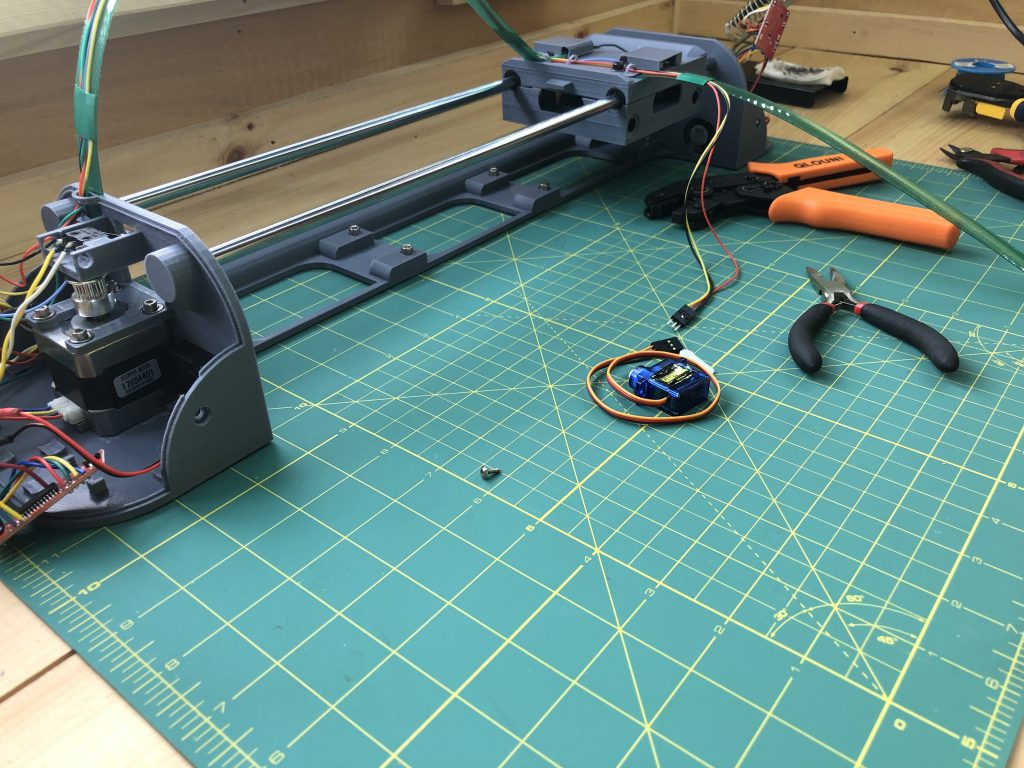

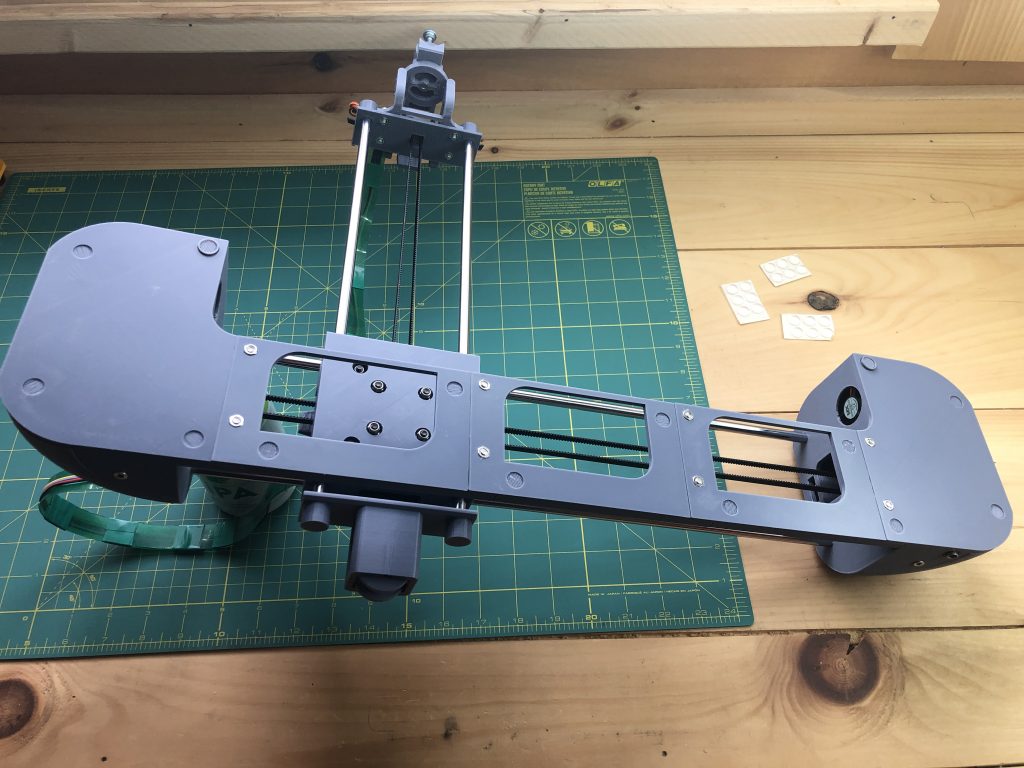

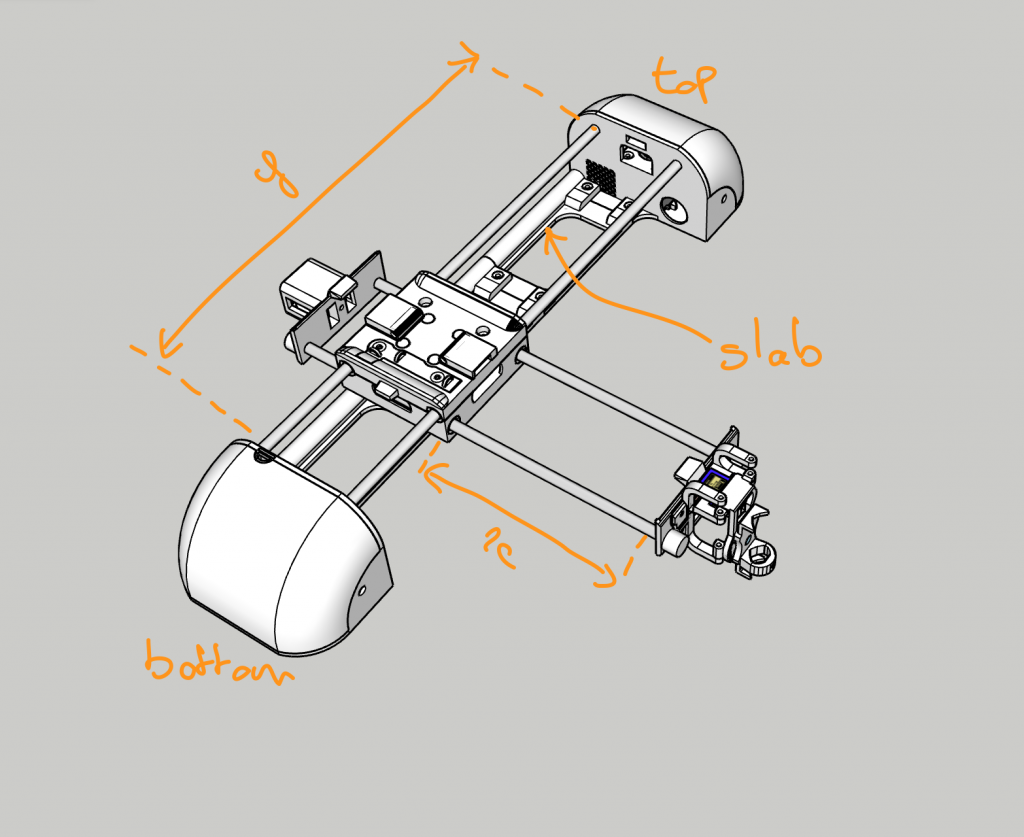

3. Main frame, the Y axis

Hardware:

8 M4x12 hex screw

12 M4 nuts

8 washers

2 M4x30 hex screws

2 linear rod 8x450mm

3D Parts:

terminal_joining_slab_x3

terminal_bottom_x1

terminal_top_x1

terminal_height_adjust_foot_x2

Electric:

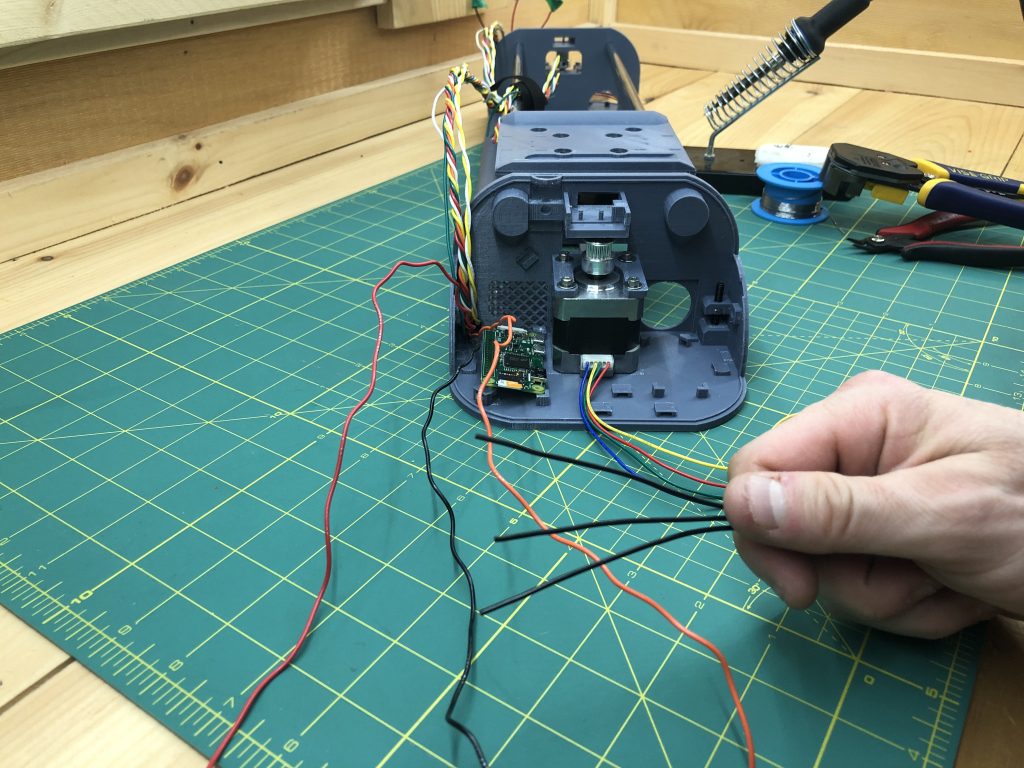

a whole bunch of wires

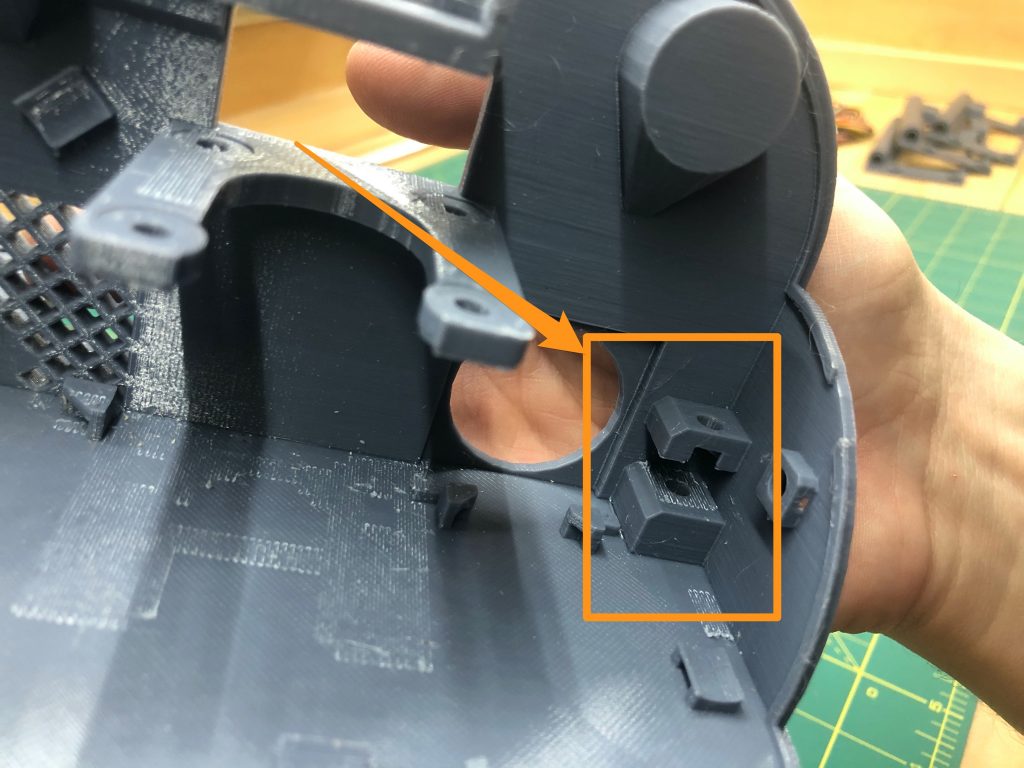

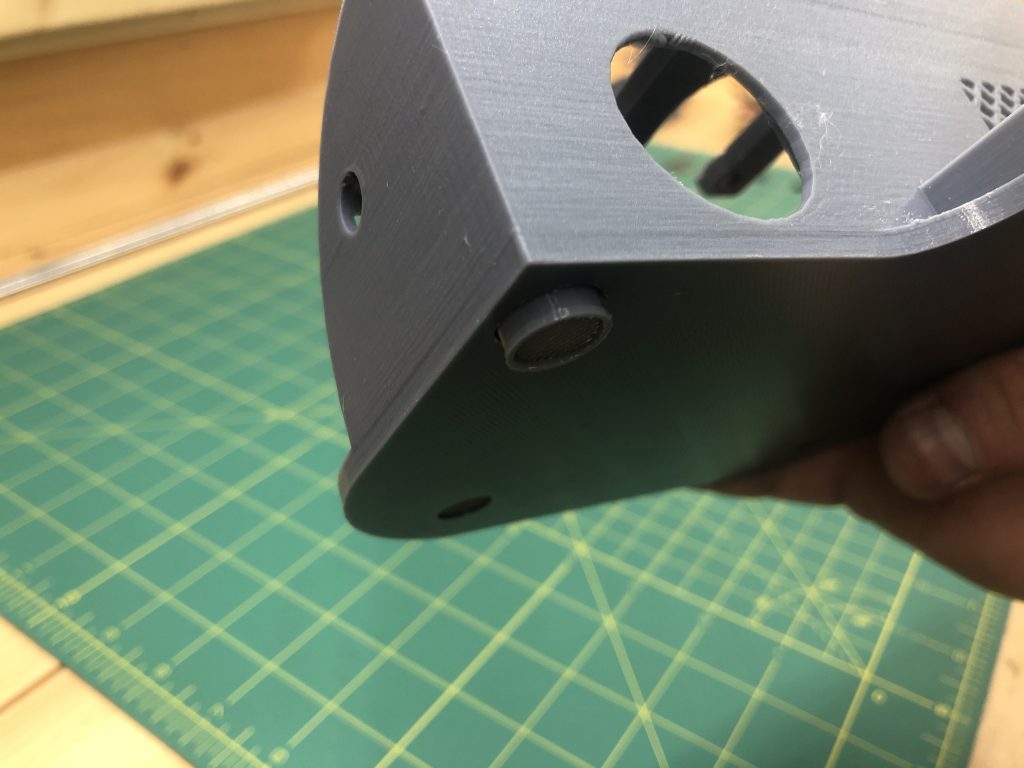

In the corner of both terminal_top and terminal_bottom, you’ll find the following:

It’s a oddly shaped assembly meant to receive 2 nuts and a screw to serve as height adjusters for your plotter. On the bottom of the terminal, where is assembly is, is a hole for a M4x30 hex screw and a receptacle for an M4 nut.

Screw the nut on the screw.

Then pressure fit it in the bottom receptacle.

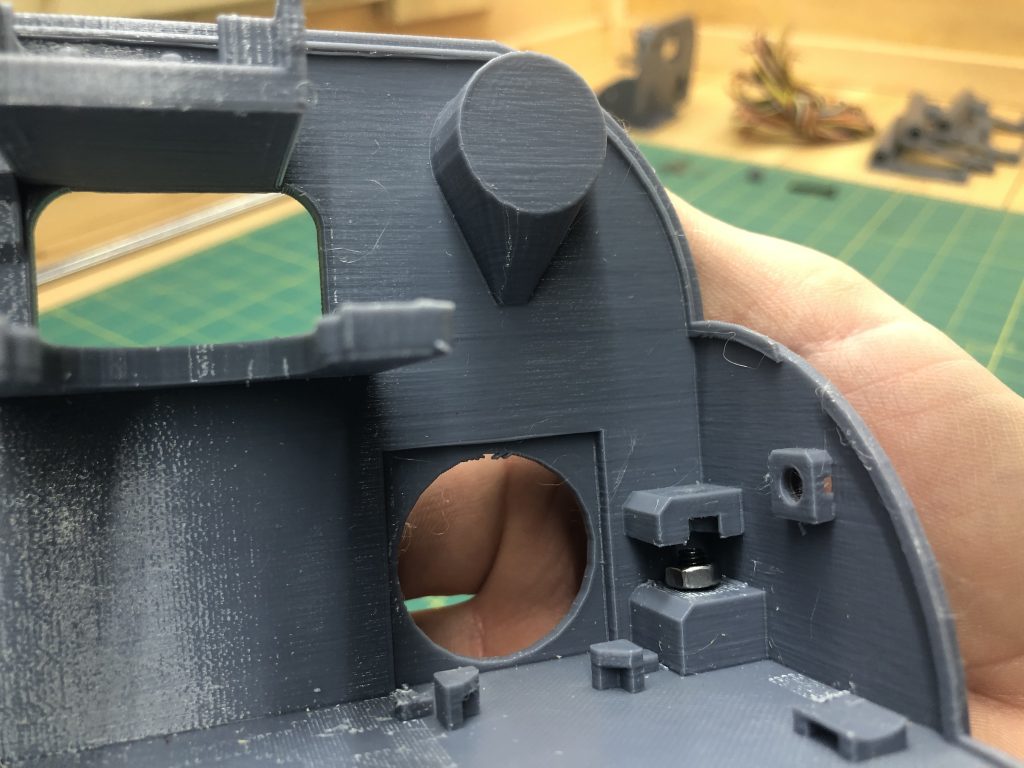

Screw into the terminal until you can see the screw.

Then add another nut.

Then screw in some more until the nut you just added is itself pressure fitted into the receptacle above it. This is a bit of a funny exercise which takes a bit of back and forth to figure out.

When you’re done you have a screw held by 2 firmly encased nuts.

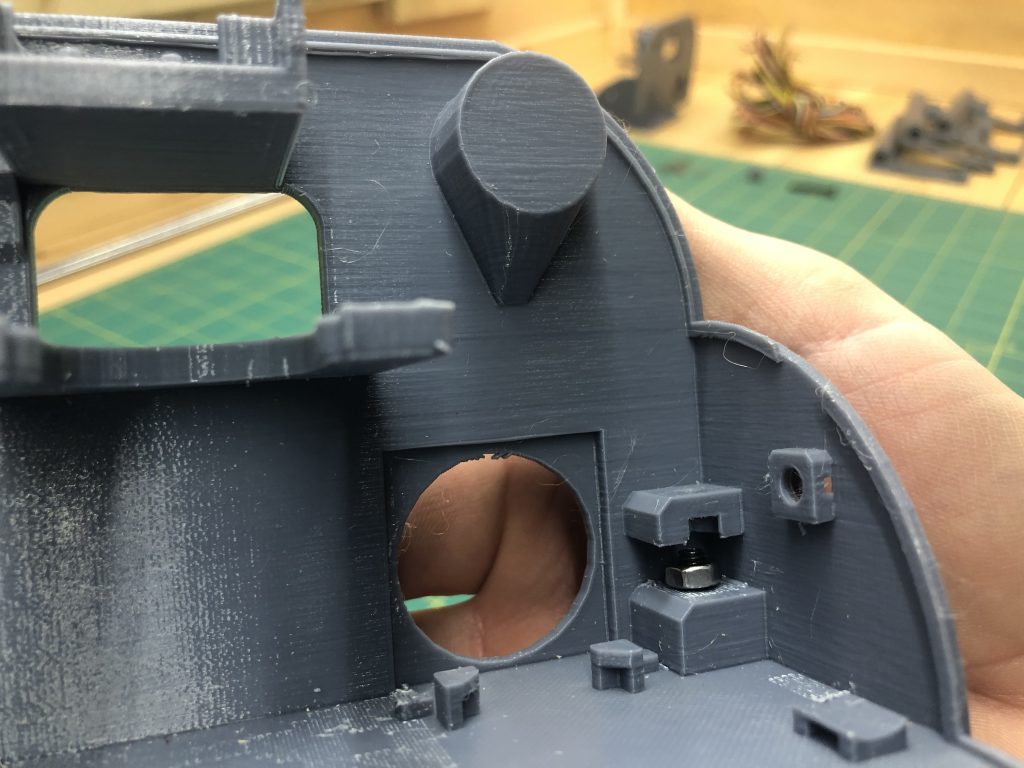

Put super glue into a terminal_height_adjust_foot end where a hex head is meant to fit a screw head.

Then pressure fit it into the screw. The gentle hammering may come in handy. I took the screw out precisely for this :).

Put the screw back in, you now have a height adjustable foot on your terminal.

Do the same for the other terminal, I’ll skip all the known steps.

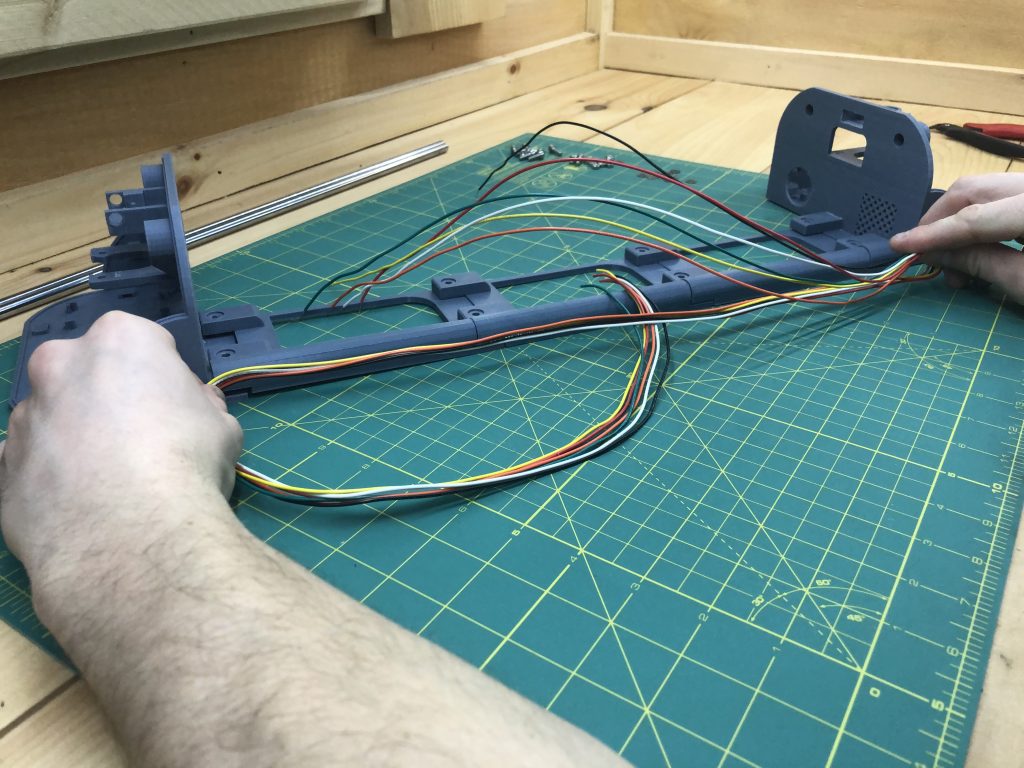

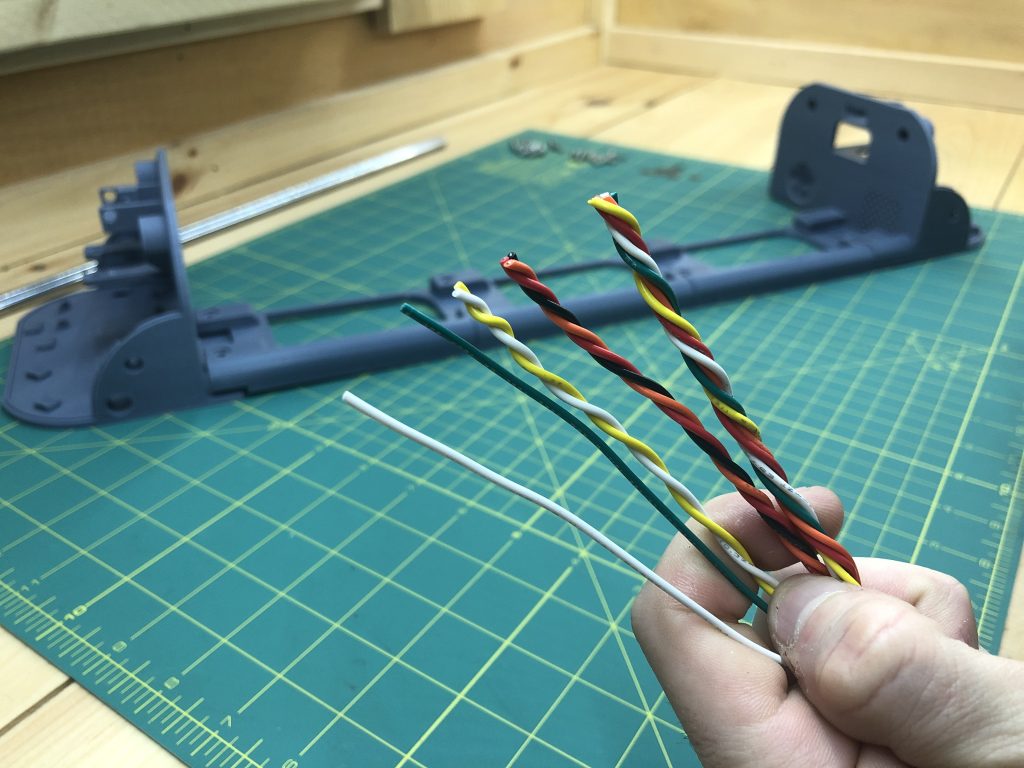

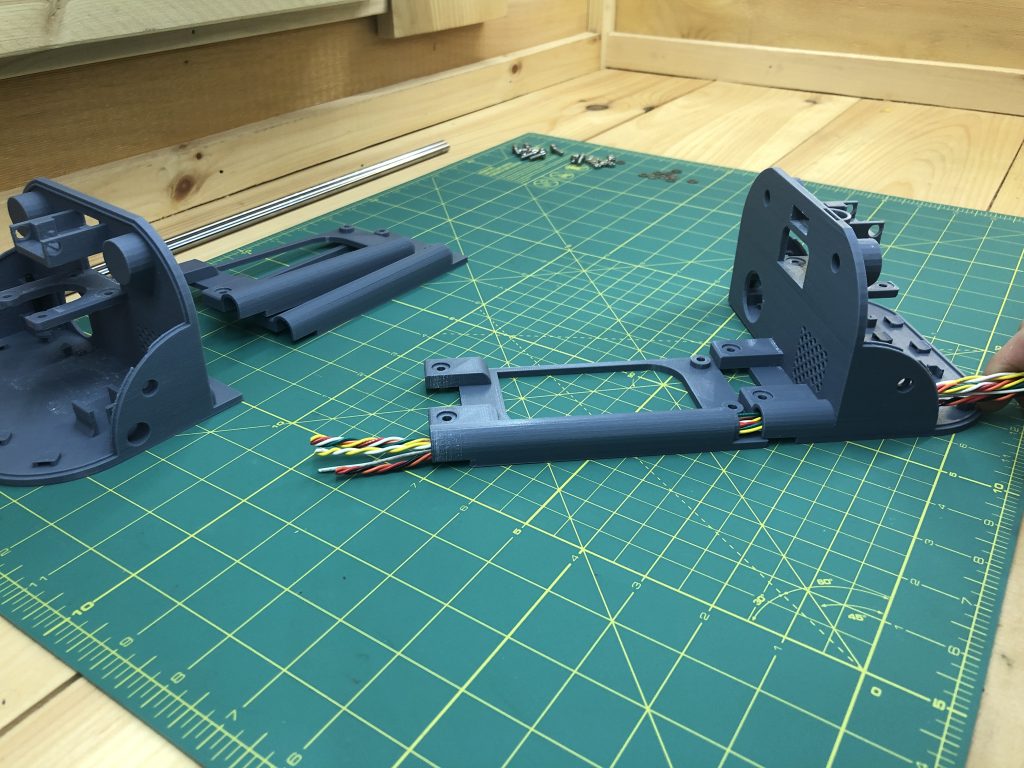

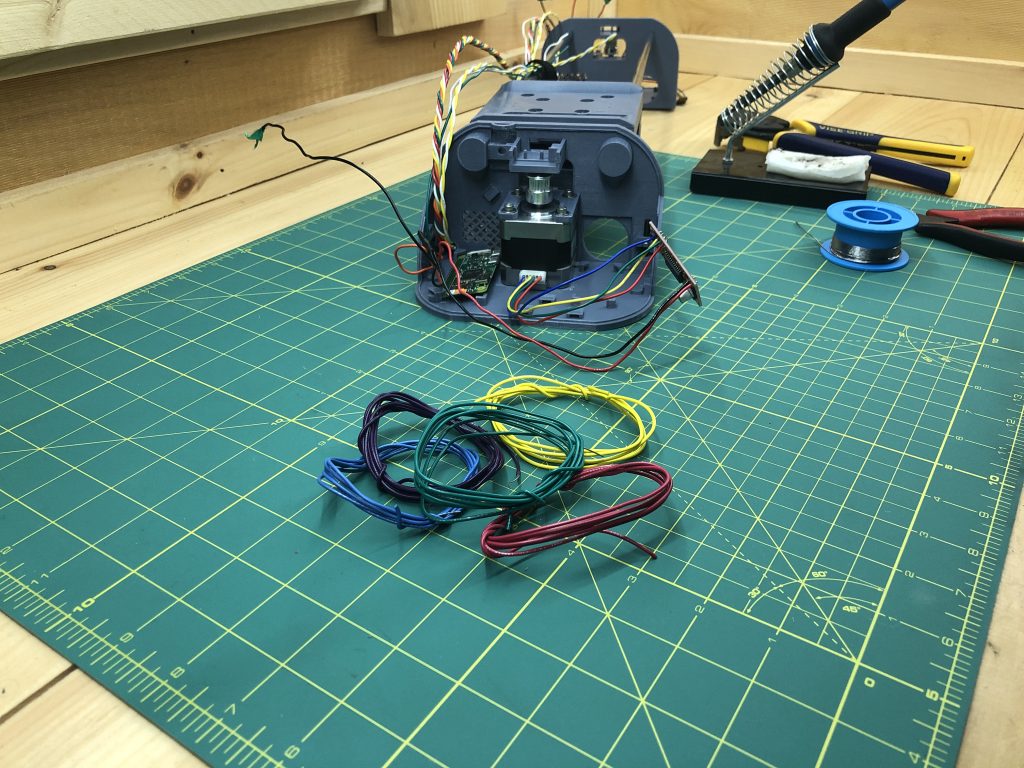

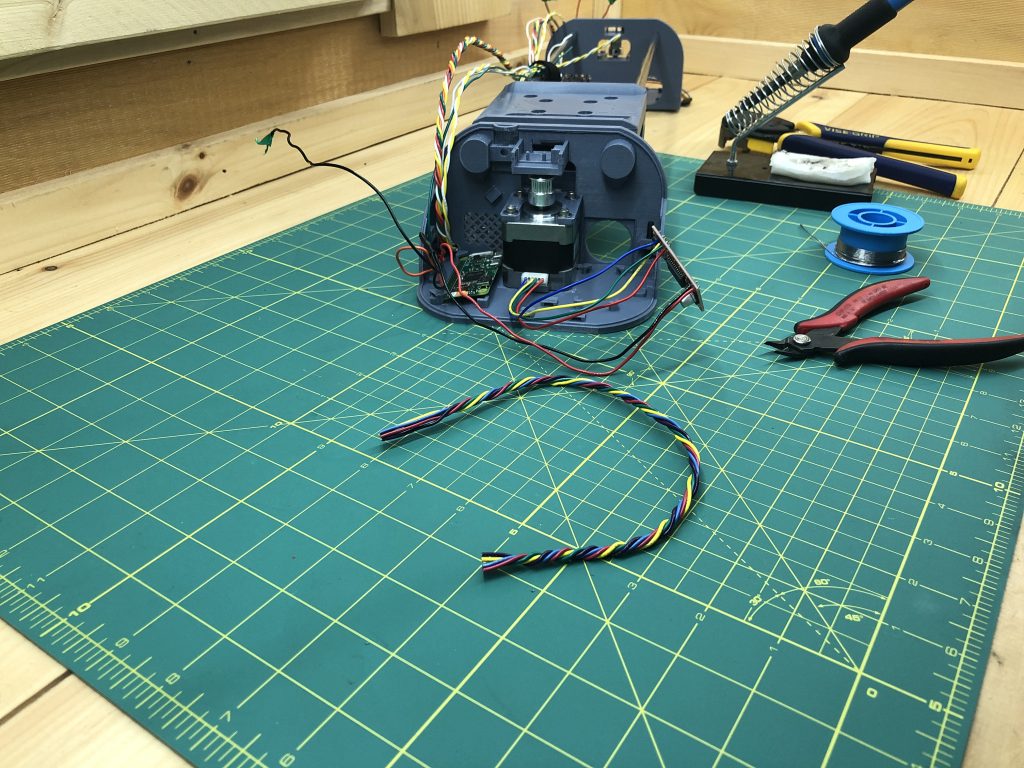

Grab 5 wires of different colors (except red and black). Cut them at 3 times the length of the distance between terminals when they are joined by their slabs (you can put them together loosely to see).

Now begins the very tedious task of twisting them lengthwise. It will help in multiple ways. First on each terminals, we’ll deal with bundles of wires known for a purpose. Second, it’ll be easier to feed them through the slabs. Lastly, I hear twisted wires help with electromagnetic interference, and well, I haven’t had any since I twisted my wires so I’ll say that’s true.

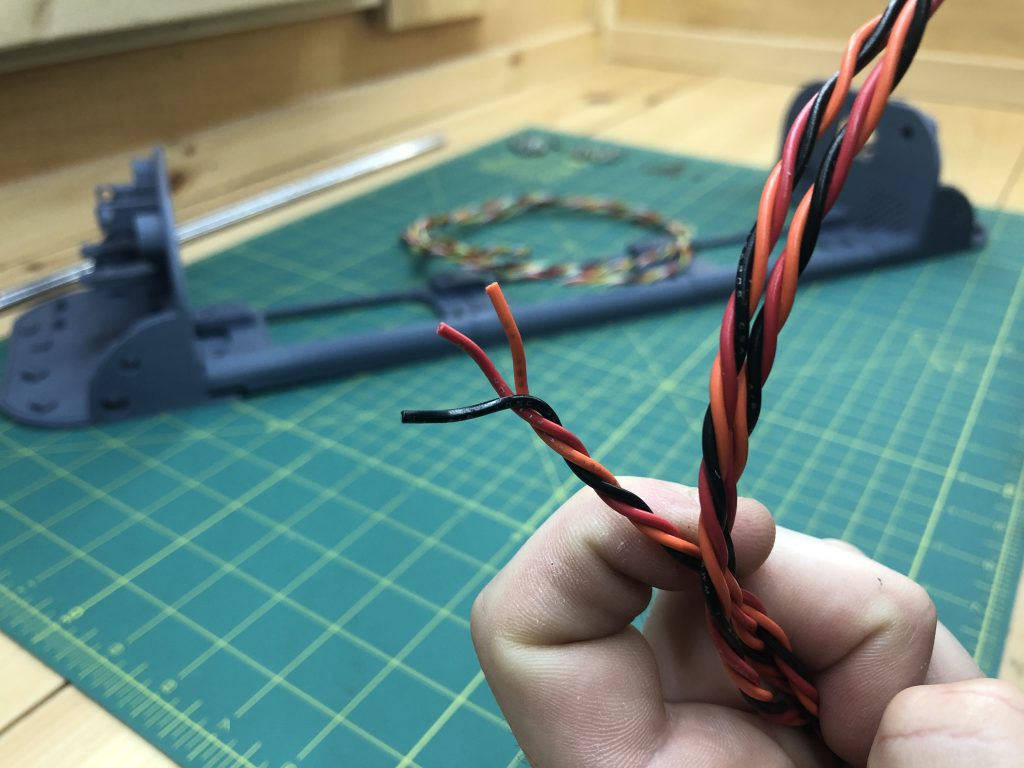

Then do another run with red, black and orange.

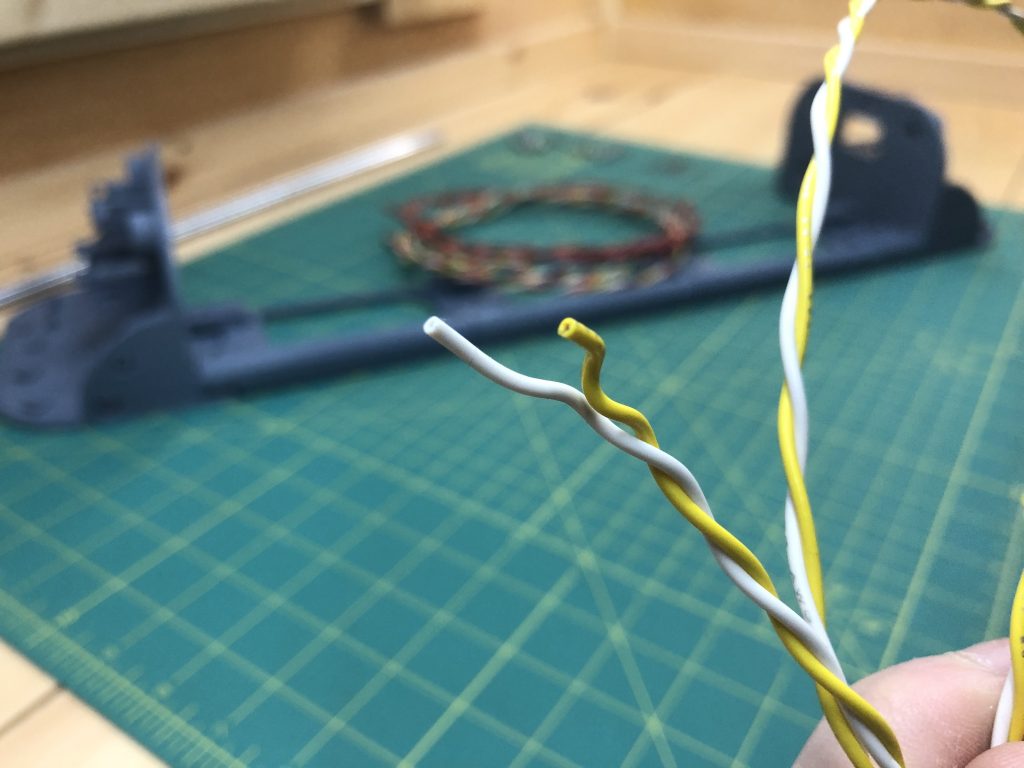

Then another with white and yellow.

Lastly, add a couple of wires of random colors to your spools, they don’t need to be twisted.

You should have the following bundles when you’re done.

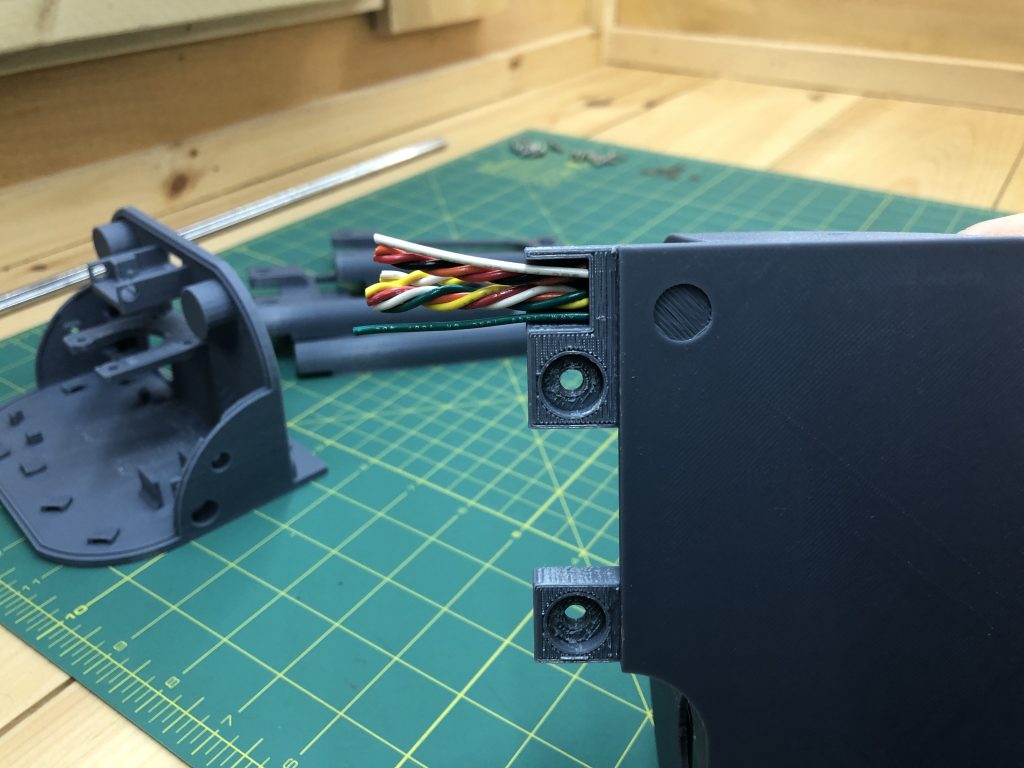

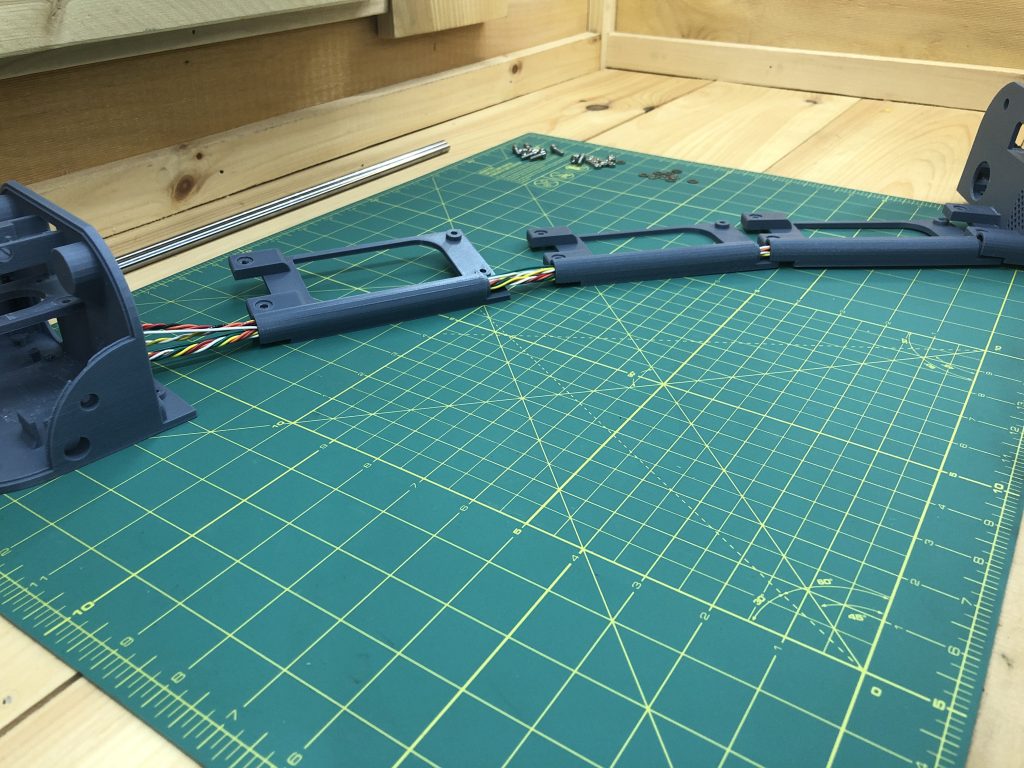

Grab them all and insert them into the bottom terminals corner, where an arch shaped hole is.

They’ll come out the other side (bottom view).

Insert them into the similarly shaped arch hole of a slab.

Until them come out the other side.

Repeat with the next 2 slabs.

And in through the top terminal.

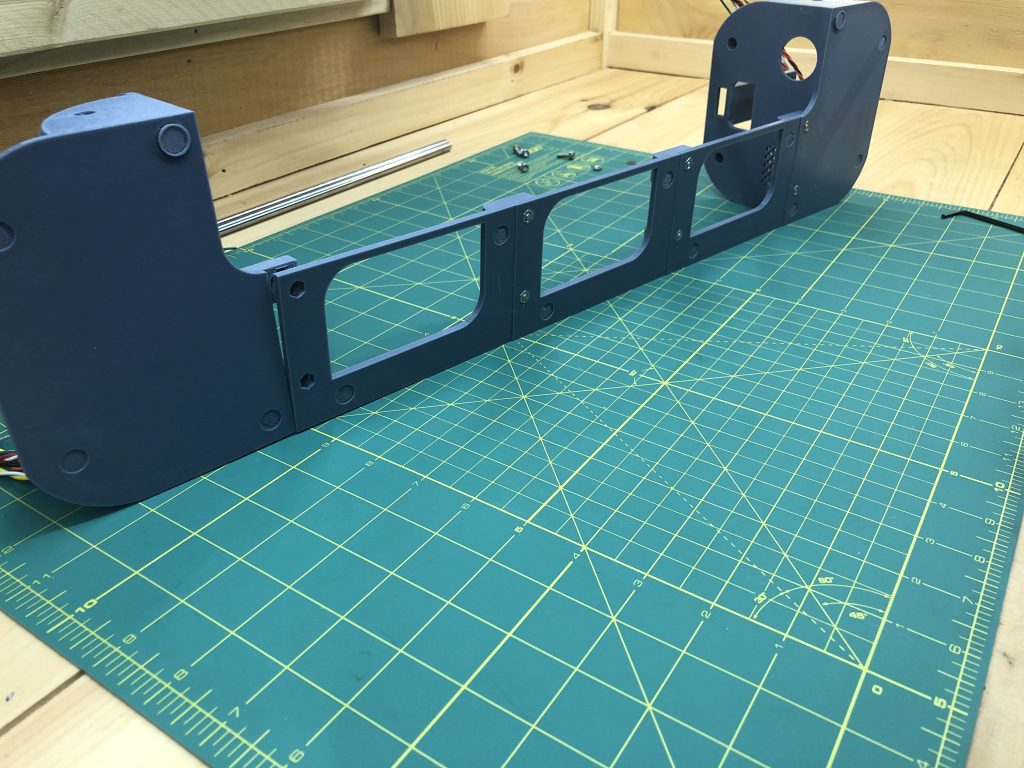

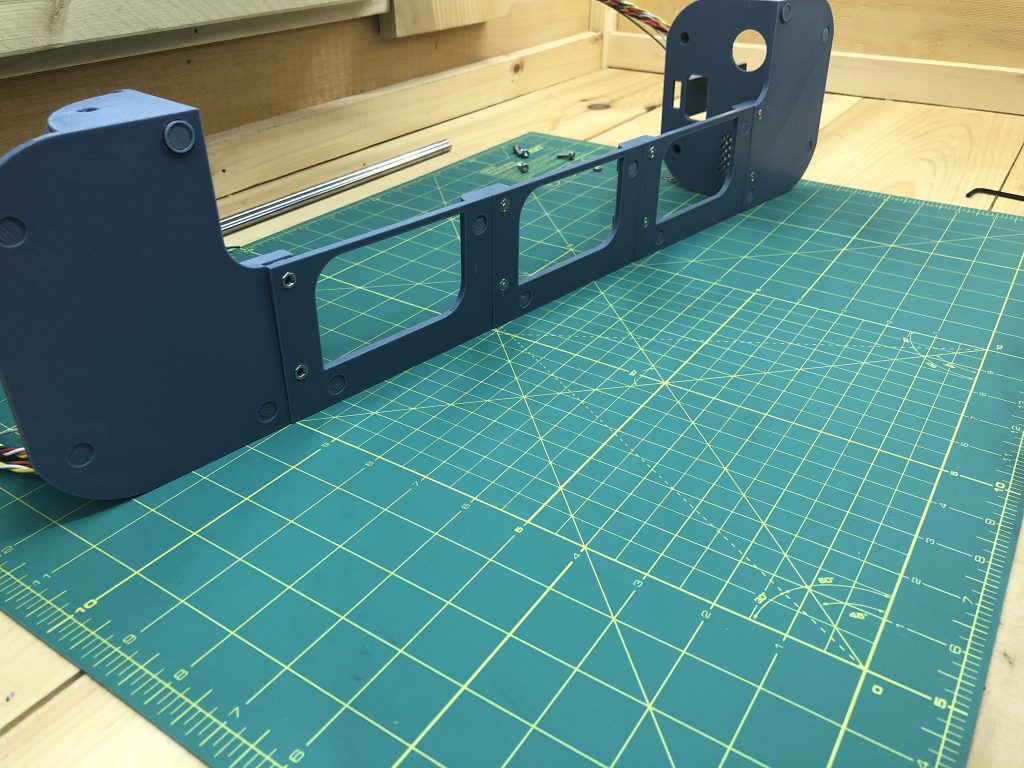

Insert M4 nuts into the bottom where receptacles exist (except for 2 where the top terminal joins).

Screw in M4x12 hex screws from the top.

Put in nuts in receptacle for the last step (not screws yet).

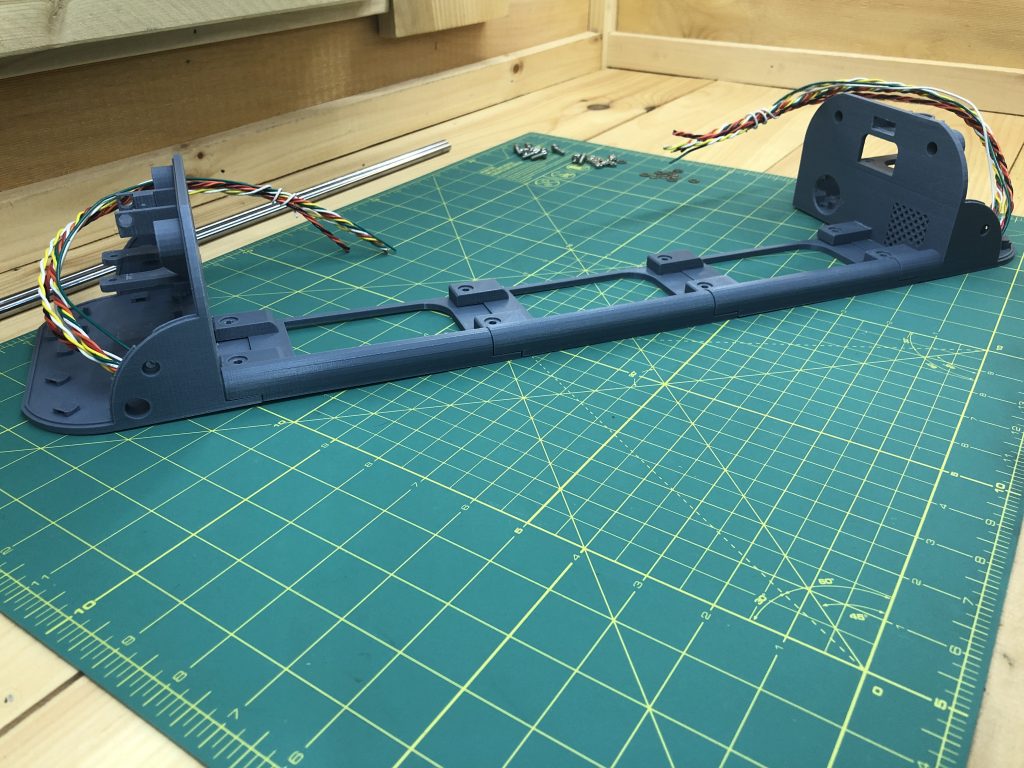

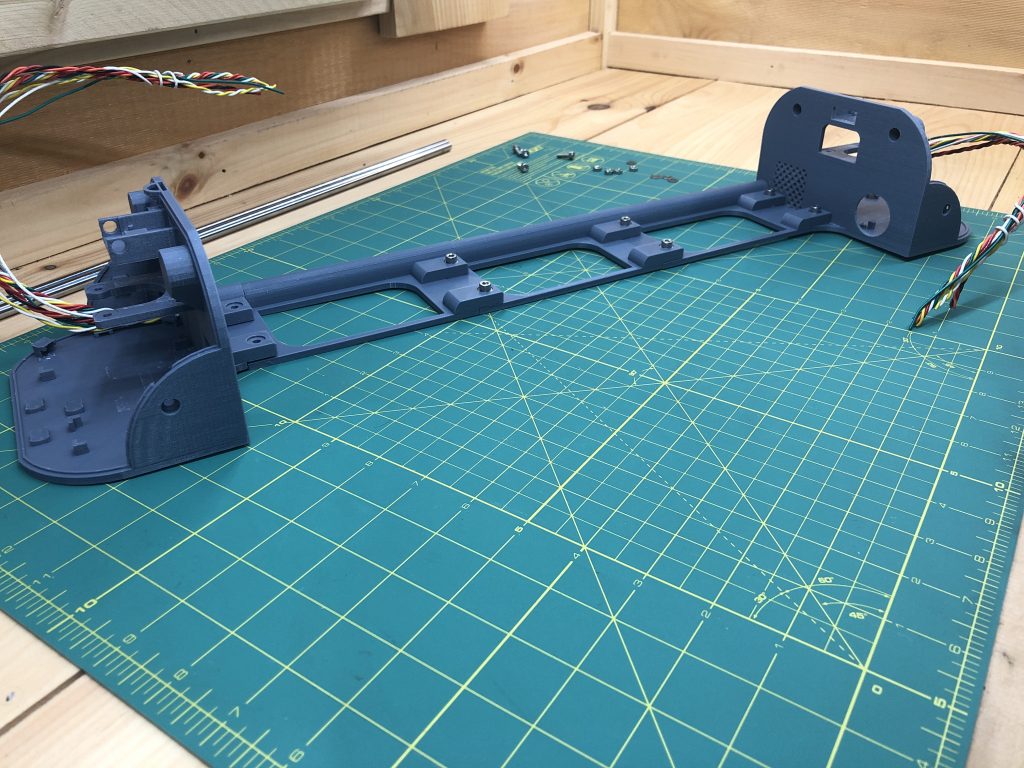

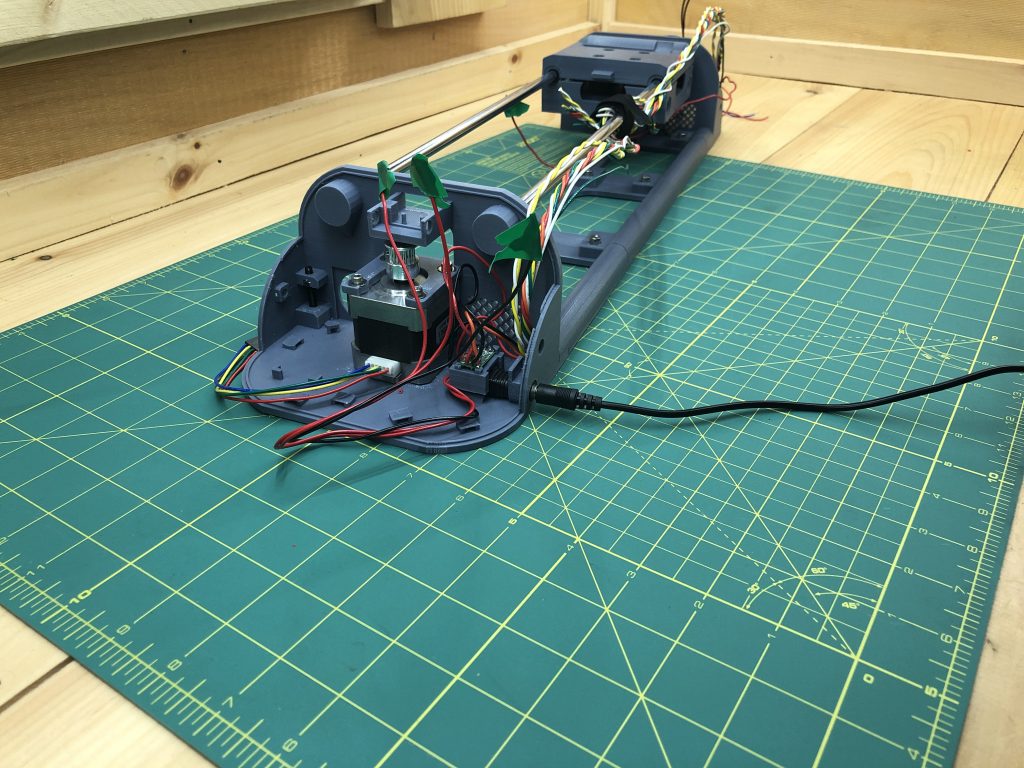

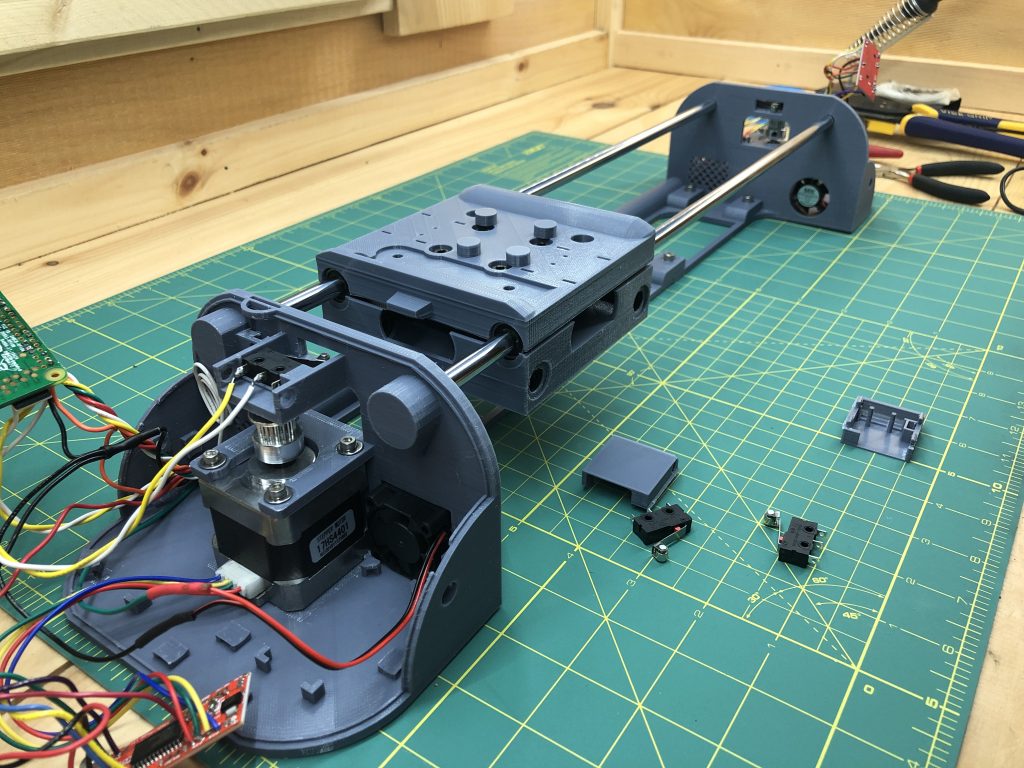

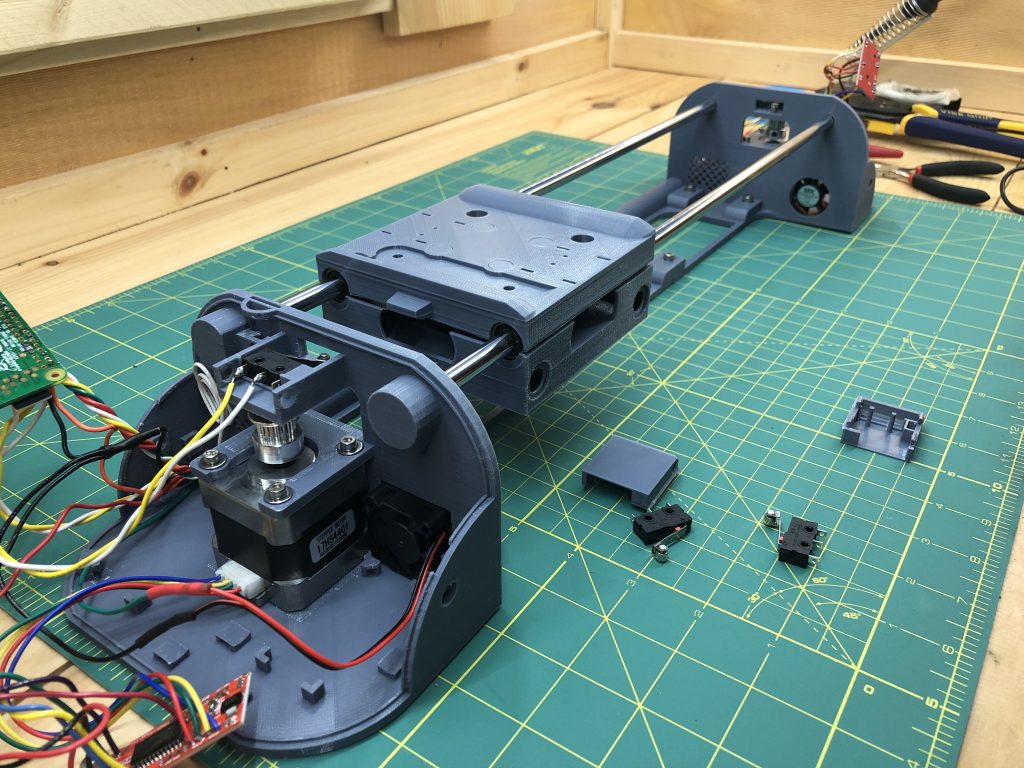

Grab your linear rods, and the gondola you build previously. Insert the rod in the bottom terminal.

If the rods don’t fit, it’s ok, 3D printers tolerances can vary. Grab a drill with a bit 8mm or smaller and very, very, very carefully make the room you need for the rod. You do not want the rods to float in their hole, it will make drawings inaccurate, they are to be firmly held. Again, do not overdrill, take your time to remove a little bit of material at a time as you try the rod.

This is all I needed to remove to get mine to fit.

With both rods into the bottom terminal, slide the gondola on. Watch for the orientation. Insert the rods into the top terminal while rejoining it to the slabs.

Put in the last M4x12 screws to commit the top terminal. Make sure the gondola slides smoothly.

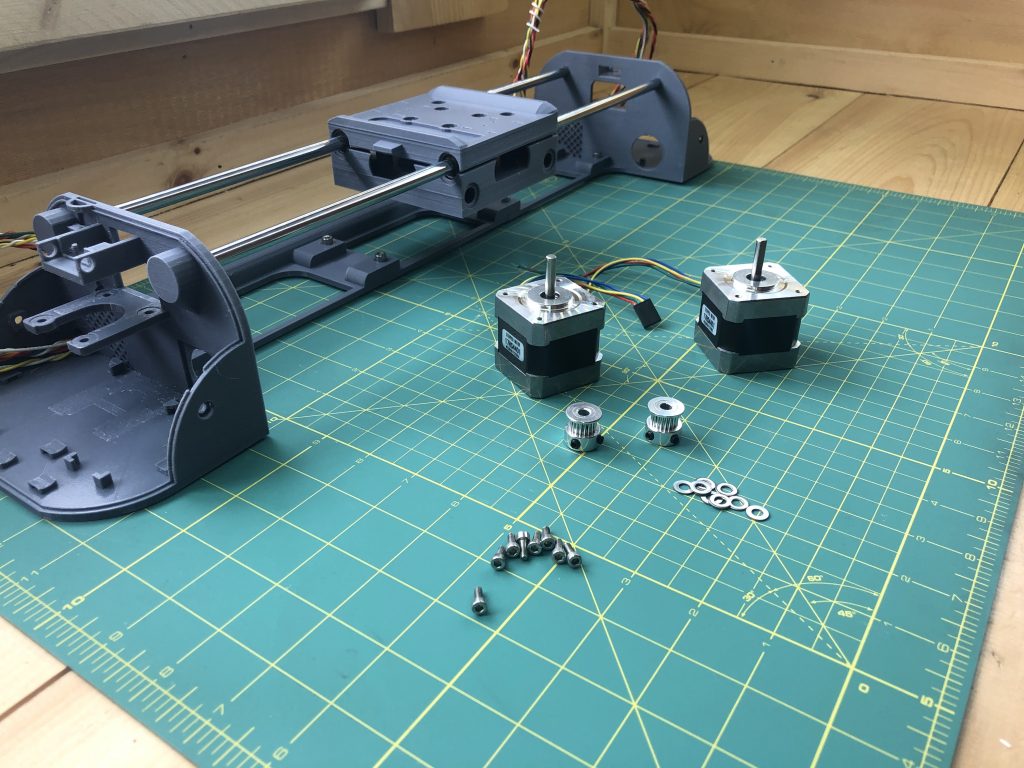

4. Stepper Motors

Hardware:

8 M3x8 hex screws

8 washers

2 GT2 20T timing pulley

Electrical:

2 stepper motor

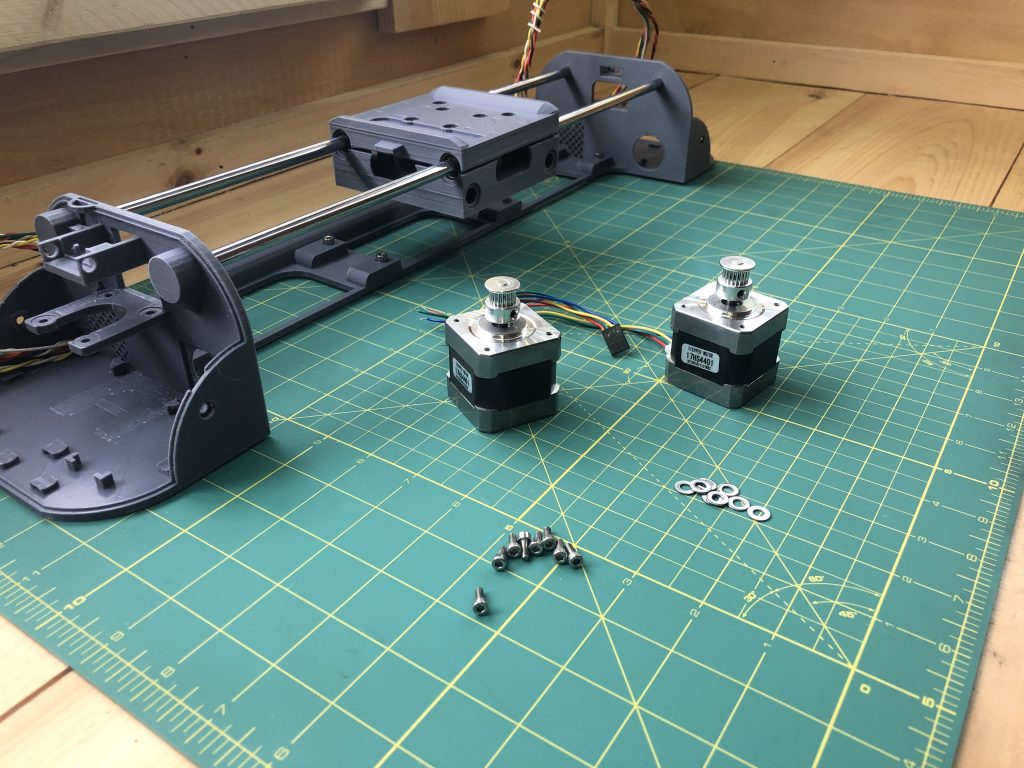

The pulleys had 2 embedded hex screws used to tighten them onto a stepper motor. Have one slightly out and one slightly in as such.

The stepper motors shafts have a flat side meant for the “slightly inside” pulley screw. This ensure that a pulley screw is tighten to the flat side which prevents slippage.

Slide the pulley on and tighten both screws. The pulley’s height wants to match that of the stepper motor’s shaft.

Do this for both motors.

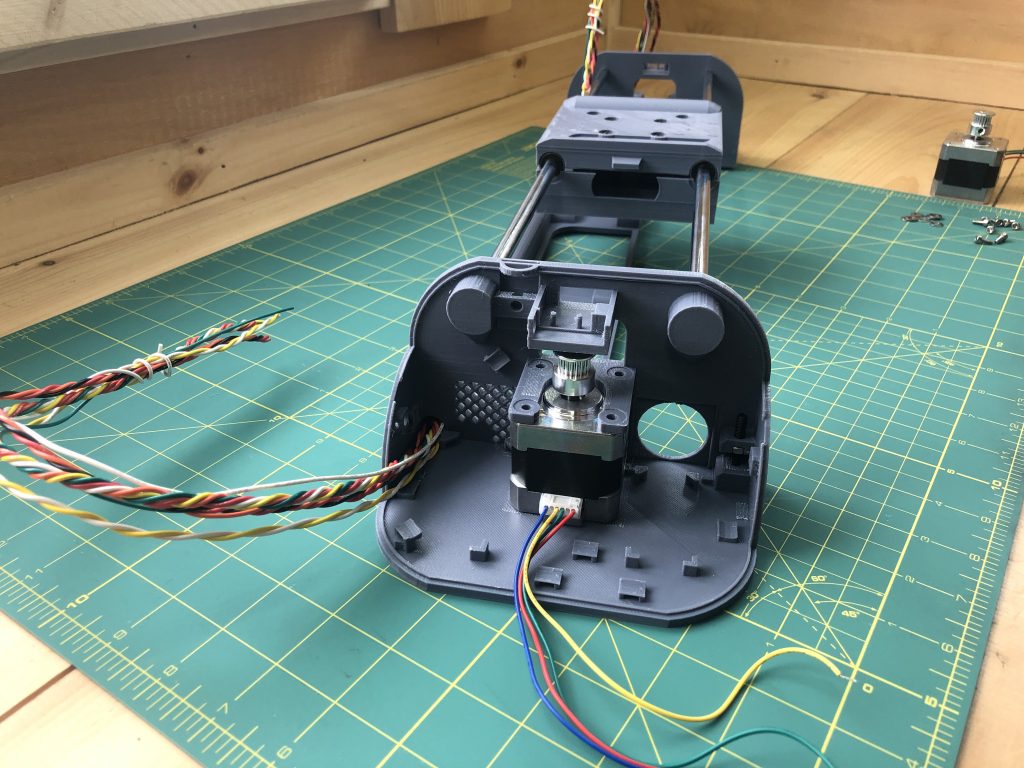

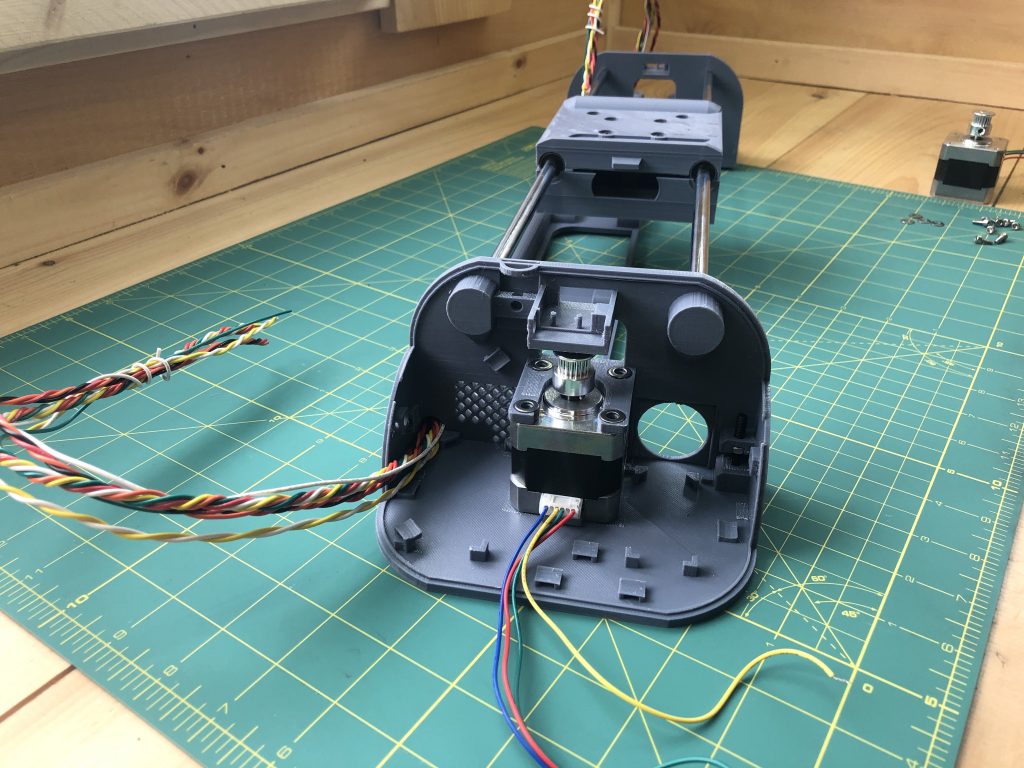

Insert a motor in a terminal.

Then it’s washers and M3x8 screws, nothing too crazy :).

Do this for both terminals.

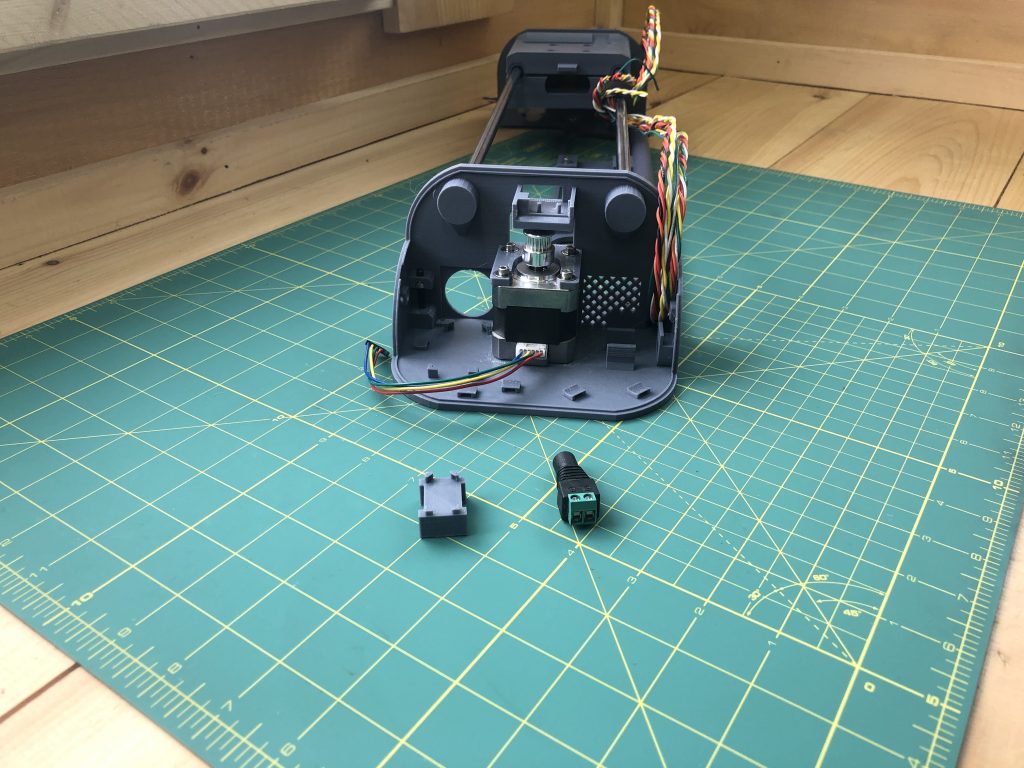

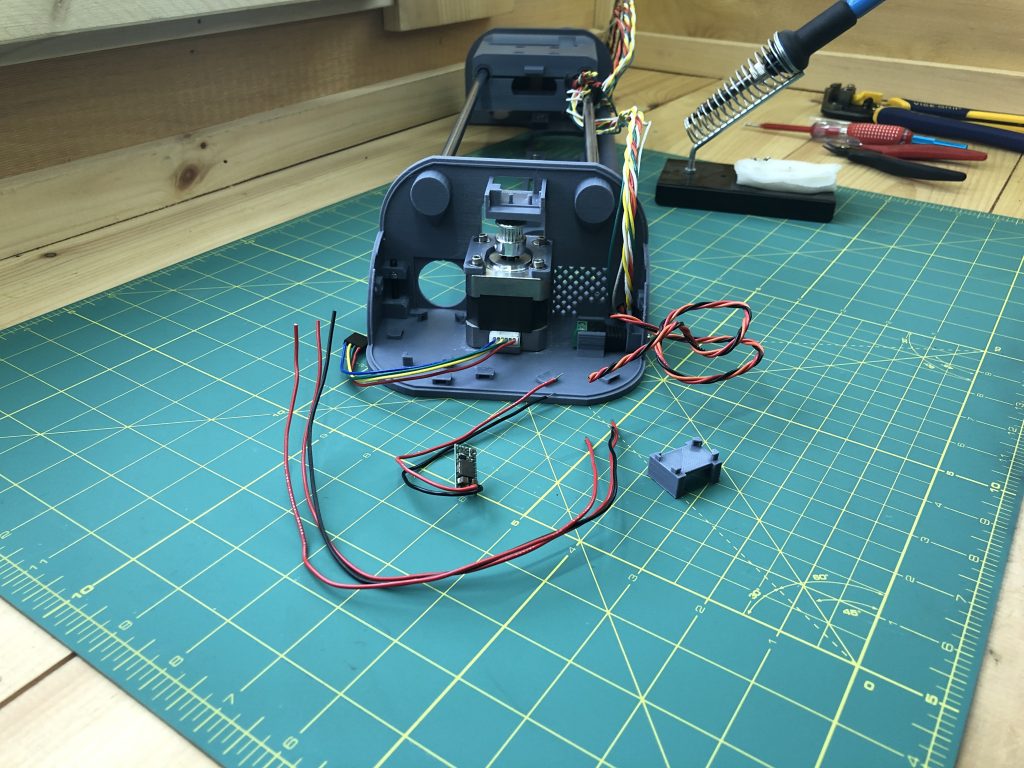

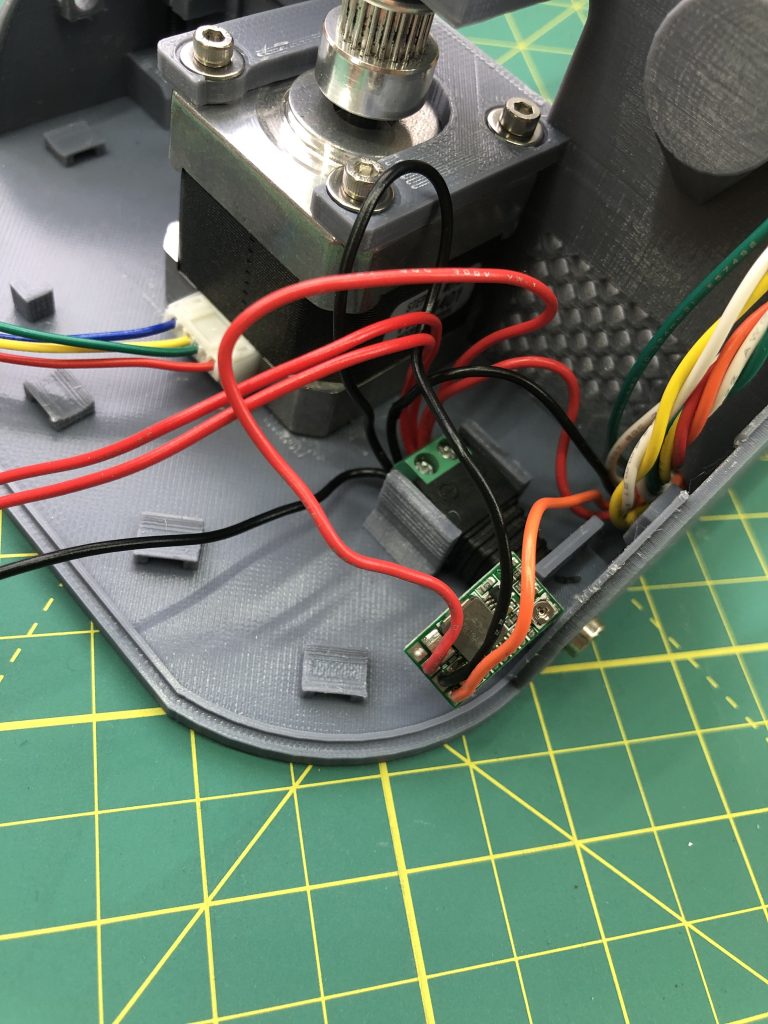

5. Power

3D parts:

terminal_top_power_supply_holder

Electrical:

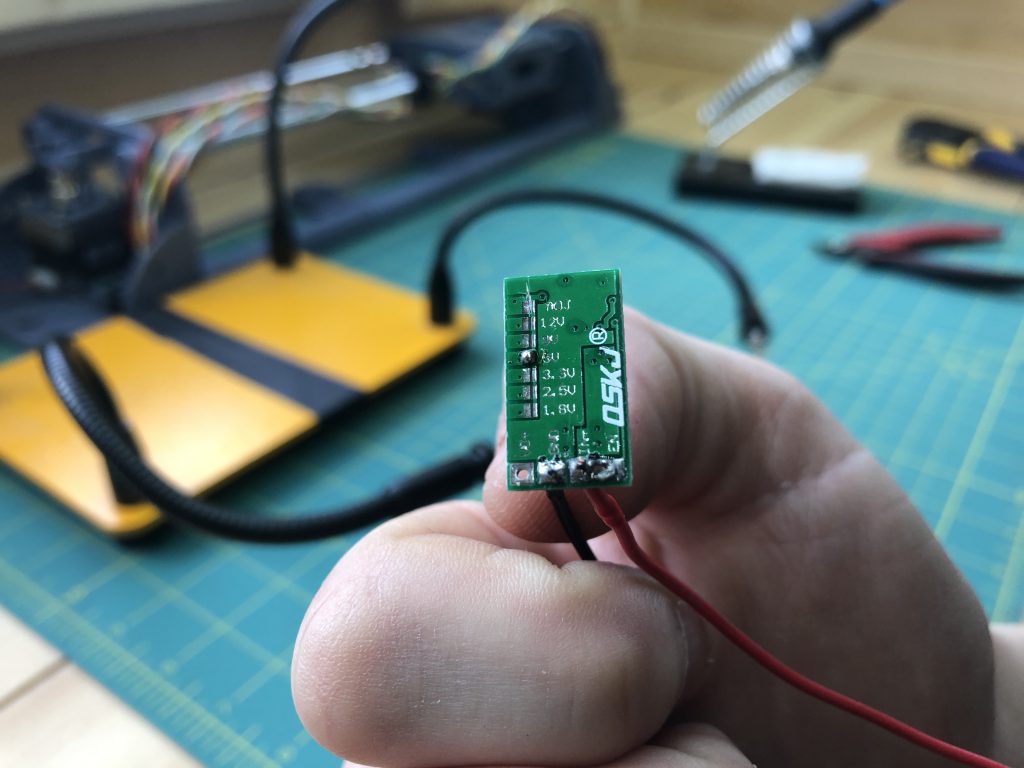

voltage regulator

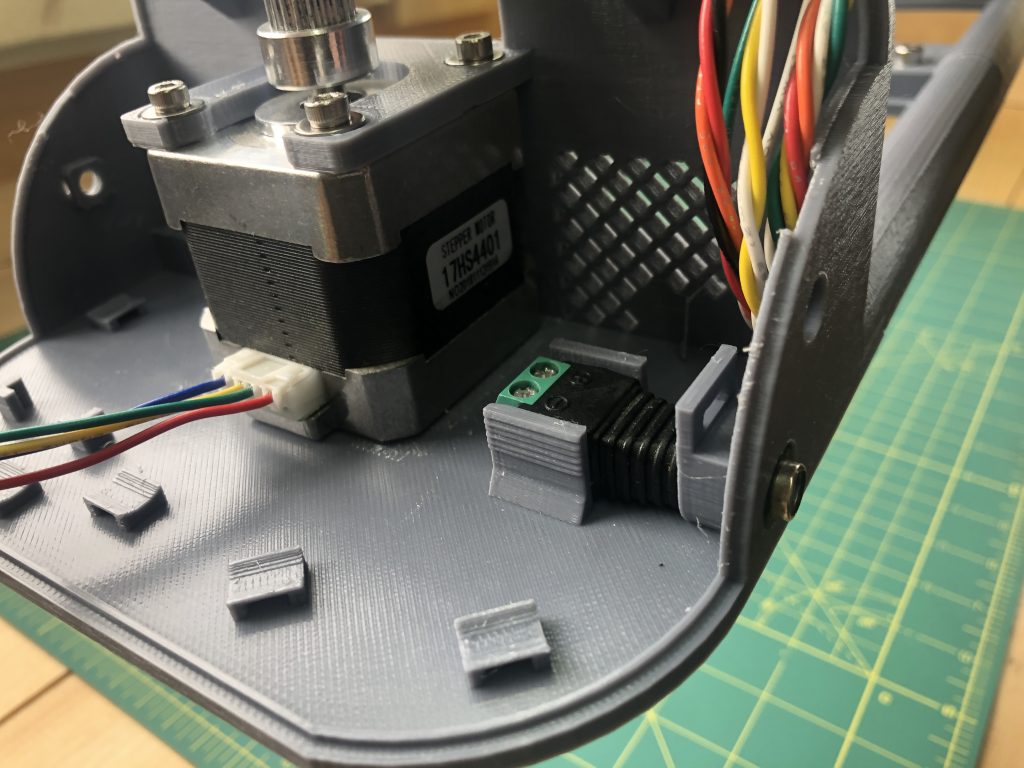

12V power supply female connector

wiring

Insert the 12V power supply female connector into the top terminal. As always, fits may be tight and fabrication and 3D printing can vary, don’t hesitate to remove material where needs be.

The voltage regulator will go on the terminal_top_power_supply_holder which crimps on, but don’t crimp it on yet. This is just to see where we’re going.

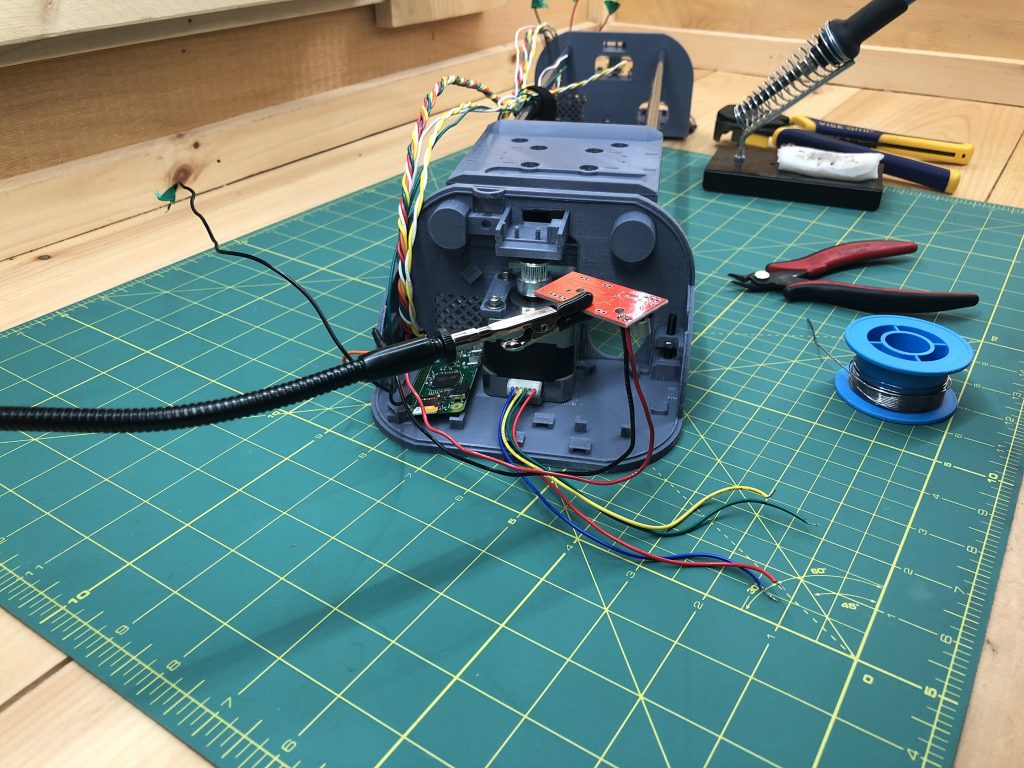

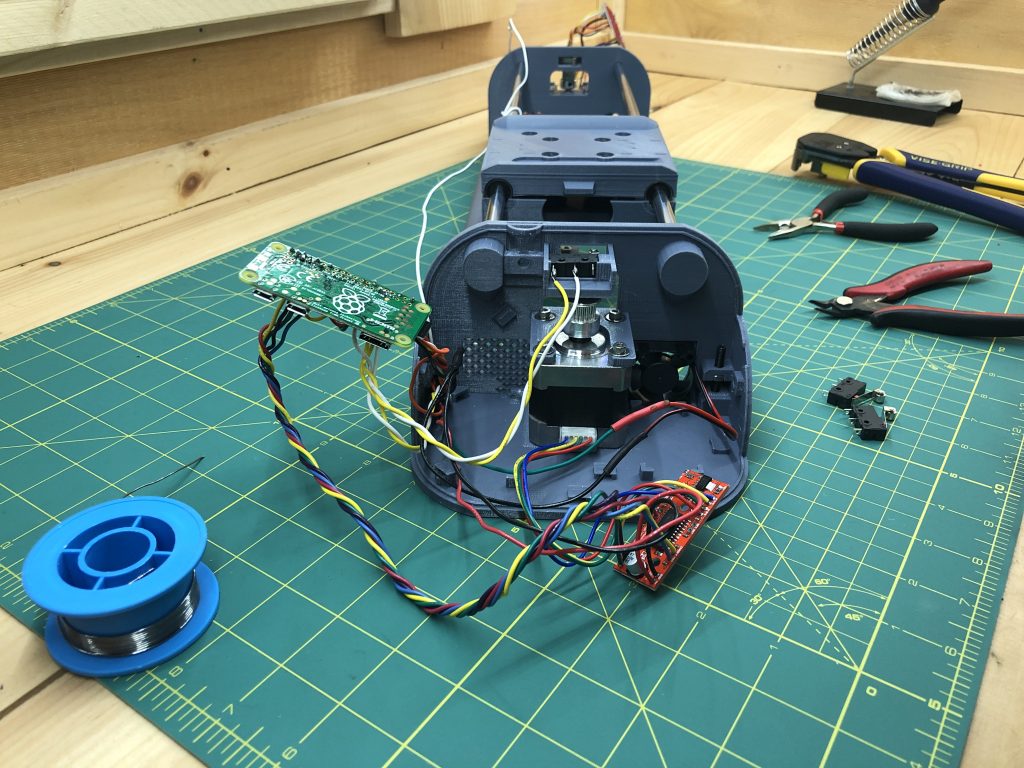

Before we proceed further, a connector interlude.

We’re about to wire electrical components. In this build I will solder them, instead you can use headers and dupont connectors which can be added and removed at will. Removable connectors are nice in that mistakes are easy to fix, and components easier to repurpose. This is what I did for several previous iterations of PlottyBot. The one I’m building now however is a final version and very much meant to plot through the ages. I want sturdy connections unaffected by plotting vibration and transport. I have plotted for hundreds of hours on dupont connectors, they are fine but will come loose on occasion. Nothing that can’t be wiggled back in place.

Choose your path, headers or connectors or soldering.

The following dupont connector set is available from Amazon. If you go this route, I recommend you try a few wires to practice on before you move on to your plotter. There’s definitely a technique to it.

</interlude>

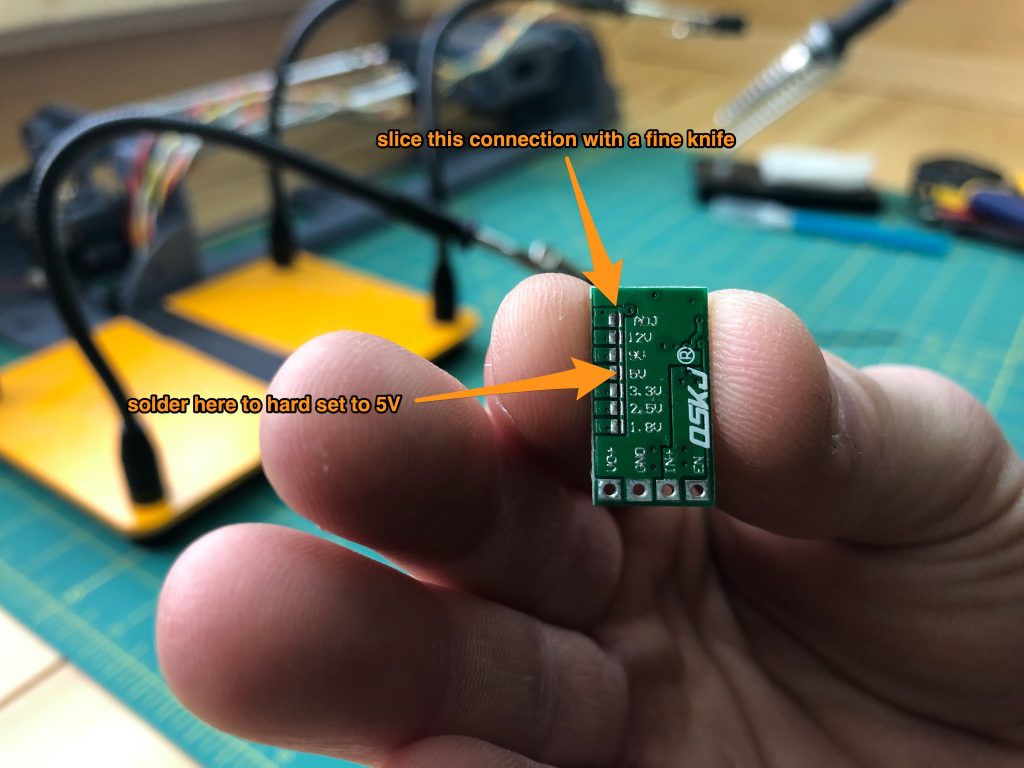

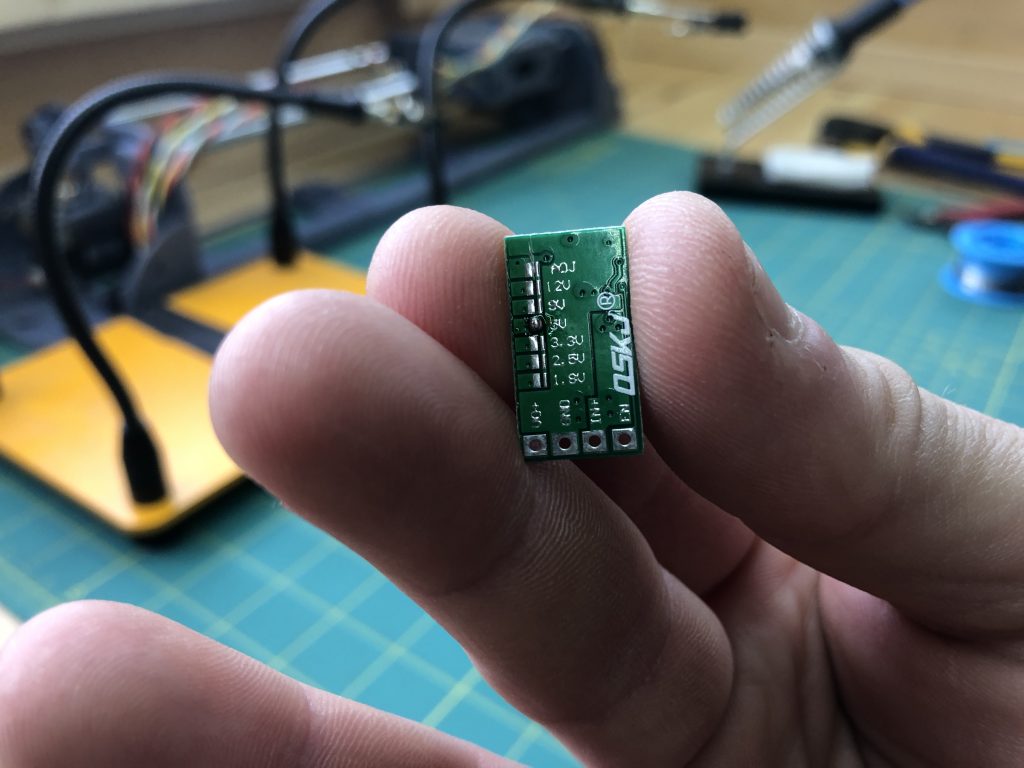

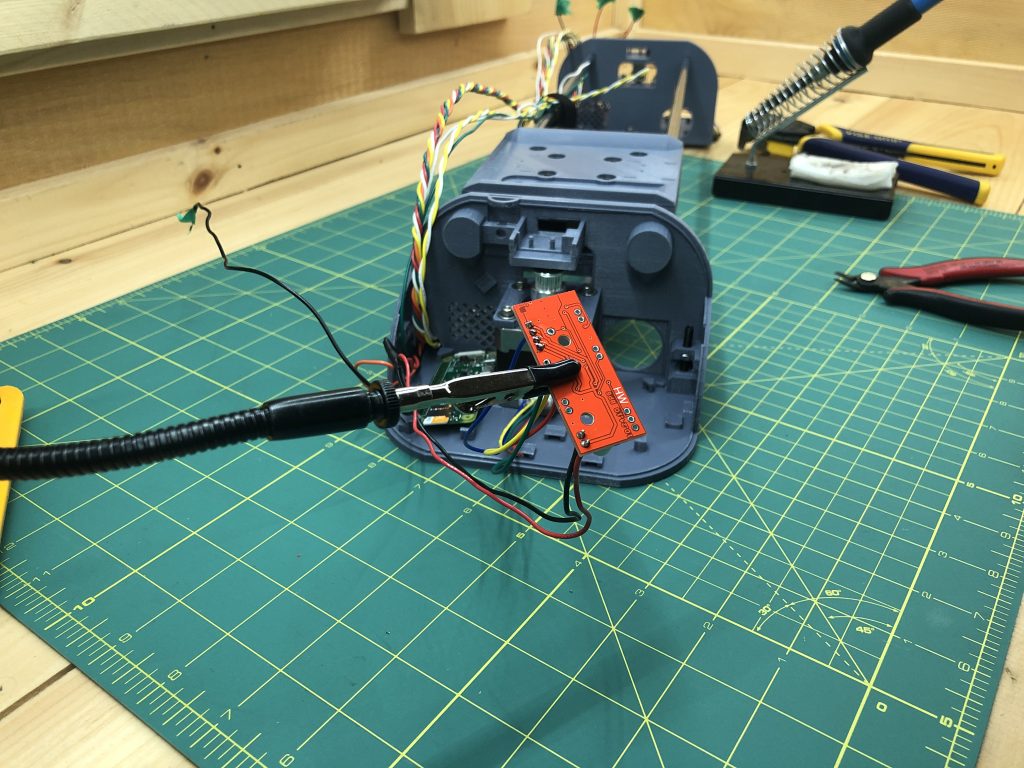

Take your voltage regulator, it needs to be set to turn 12V into 5V. We’ll tell it to not use the adjuster (a tiny rotating potentiometer on the other side), and instead hard set it to 5V to supply power to the Raspberry Pi. Definitely zoom in on the next picture to see exactly what to do.

After a little work with the exacto knife and the soldering iron.

Grab a new black wire (not one already in the plotter), strip it and solder it to the GND. I have this wonderful tool to strip wires.

Grab another new red wire and wire it into IN+. When you do so, also join IN+ with EN. It will make the voltage regulator always enabled.

I am not a good solderer and if it works, I’m all right with it :).

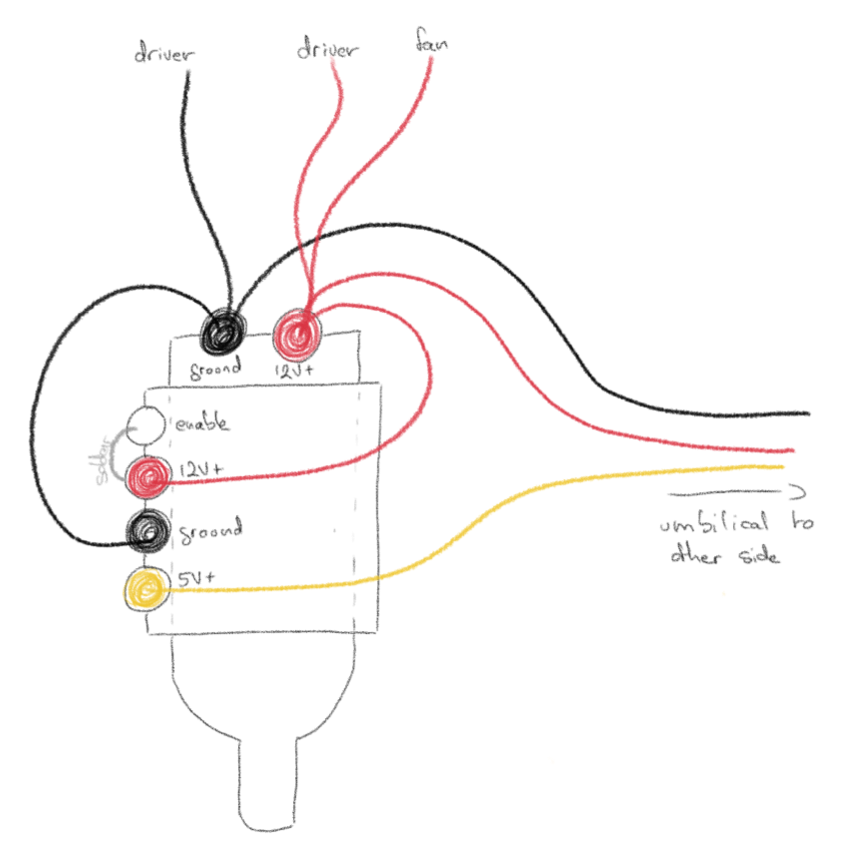

Grab a couple more red wires and a black one long enough to travel from the 12V power supply female connector to various parts of the terminal (plus some slack, it’s always easier to shorten a wire than to lengthen it). Also pull out from the umbilical of twisted wires joining both terminal the red/orange/black bundle.

Solder the orange wire from the bundle into VO+ of the voltage regulator.

Unscrew both screws of the 12V power supply female connector to ready it to take wires.

Insert into the 12V+ side, the red wire from the red/orange/black bundle, the red wire from the voltage regulator, and the 2 new red wires you made. That is 4 red wires total on the 12V+ side.

On the Ground side, insert the black wire from the red/orange/black bundle, the black wire from the voltage regulator, and the 1 new black wire you made. That is 3 black wires total on the ground side.

Here’s what this will look like when this is done schematically.

And with the usual photos.

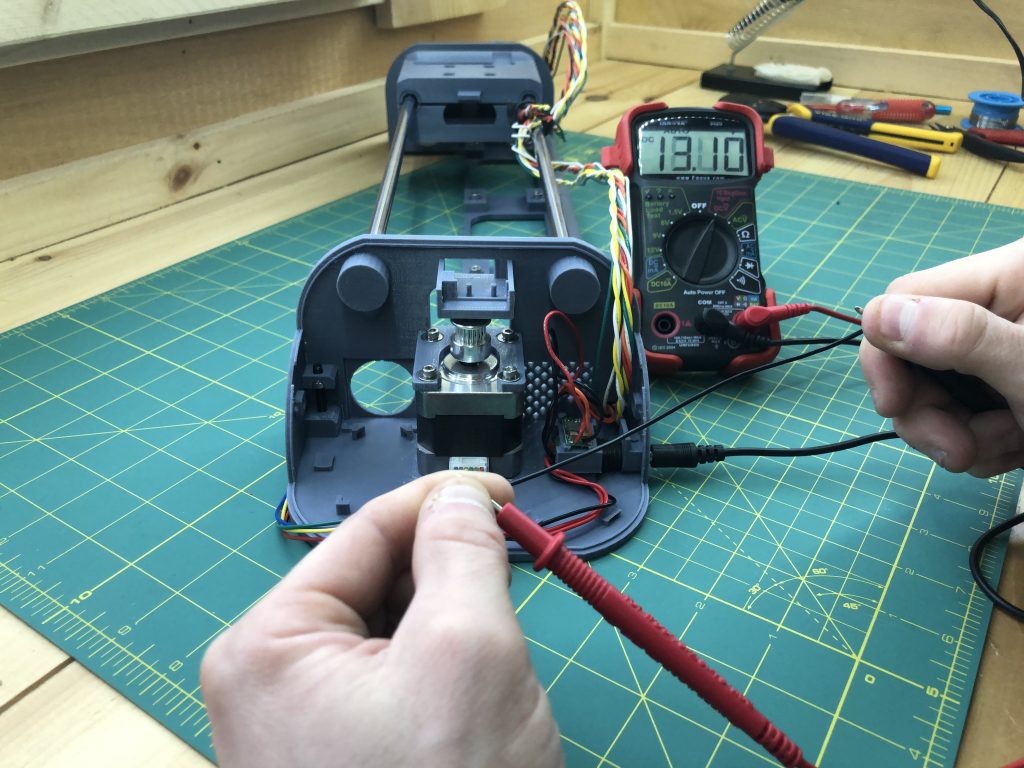

Let’s plug the plotter into a source of power and make sure that we get the proper voltages where we think we have them. Every red/black combo should give us approximately 12V (emphasis on the approximately).

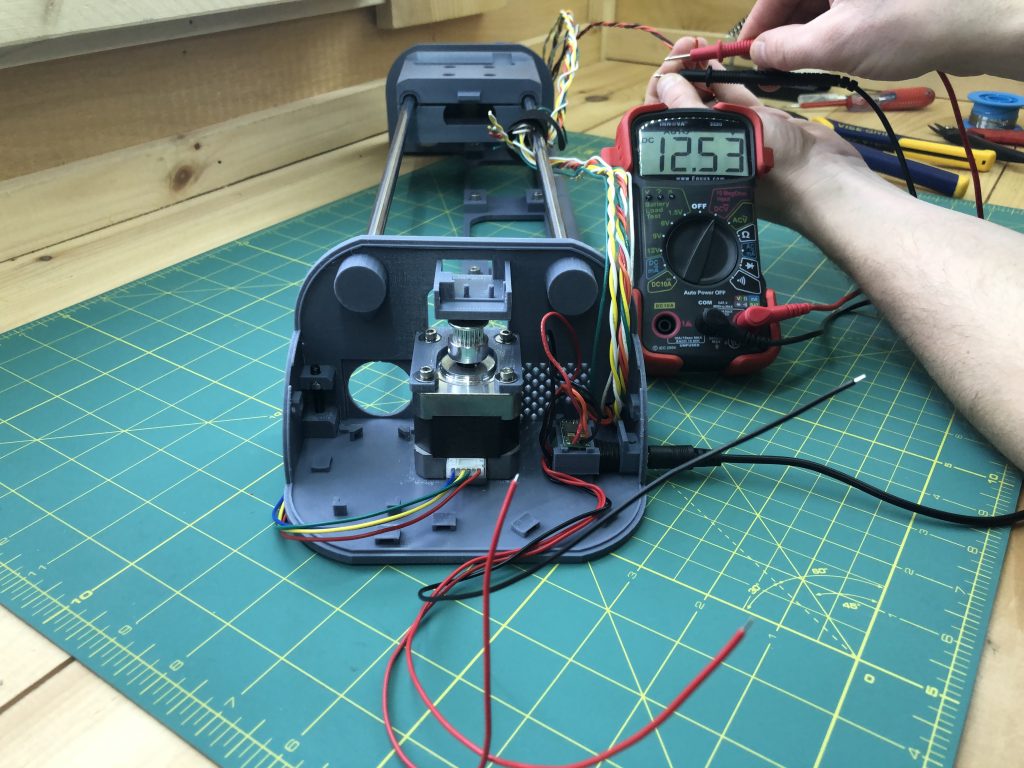

Even at the opposite terminal.

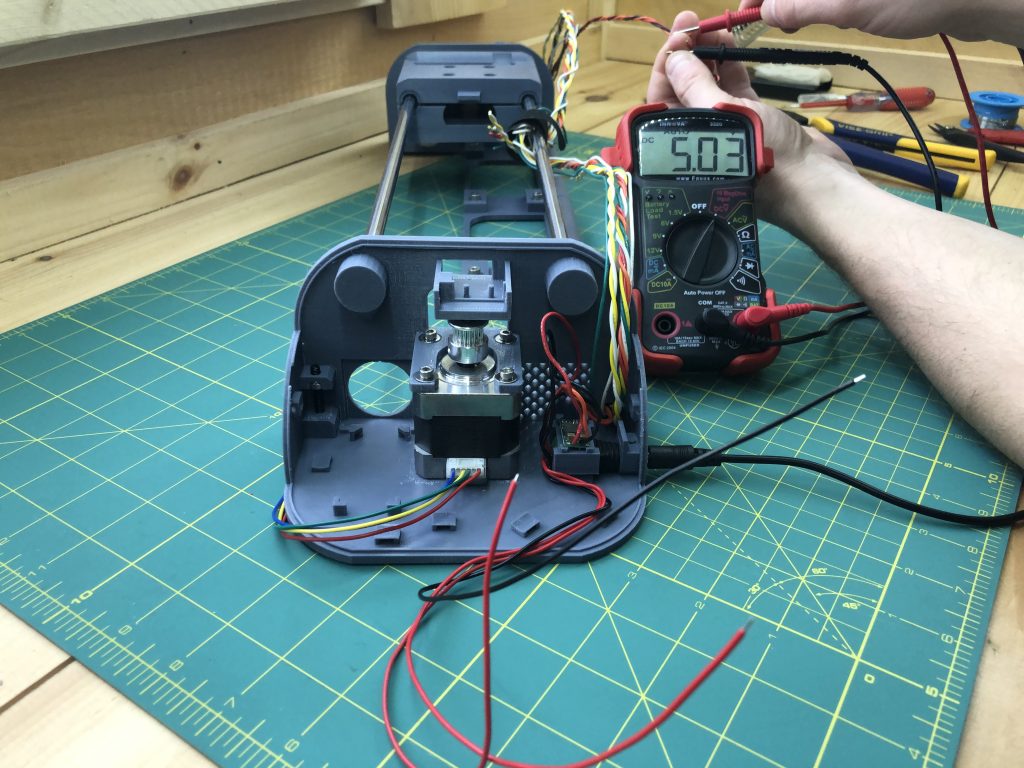

Also at the opposite terminal, the orange/black pair from our power bundle should give us 5V. This is what we’ll use to power the Pi.

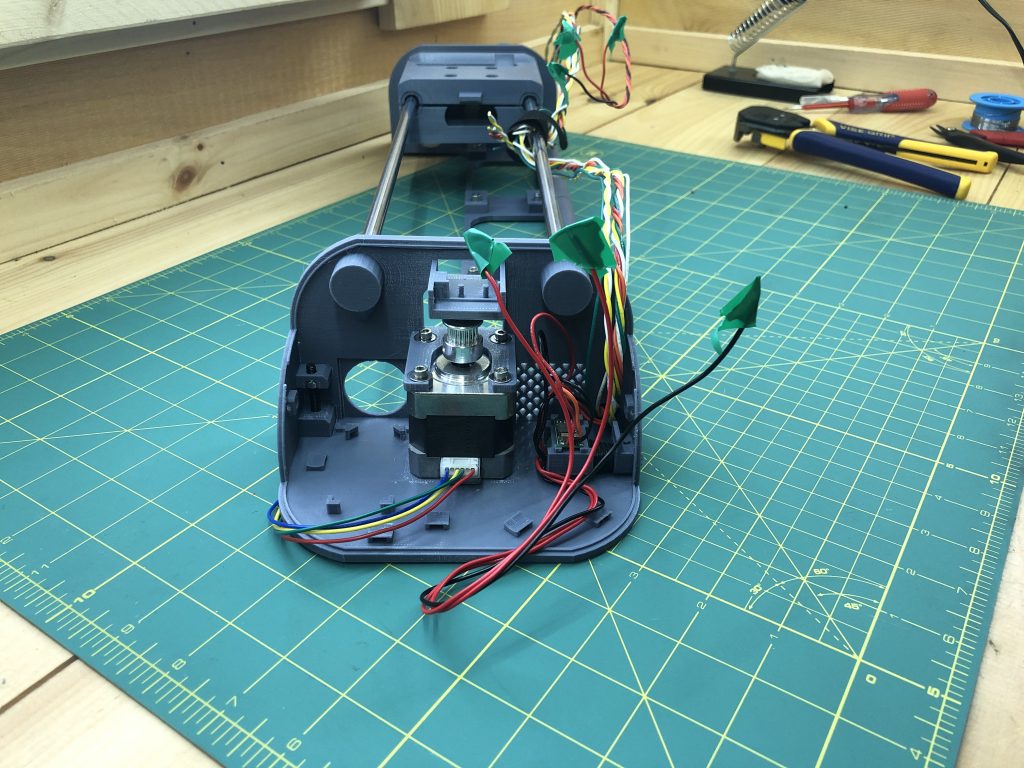

When you are satisfied that it all looks good, put some electrician tape at the tip of these wires to be safe. We won’t use all of them immediately.

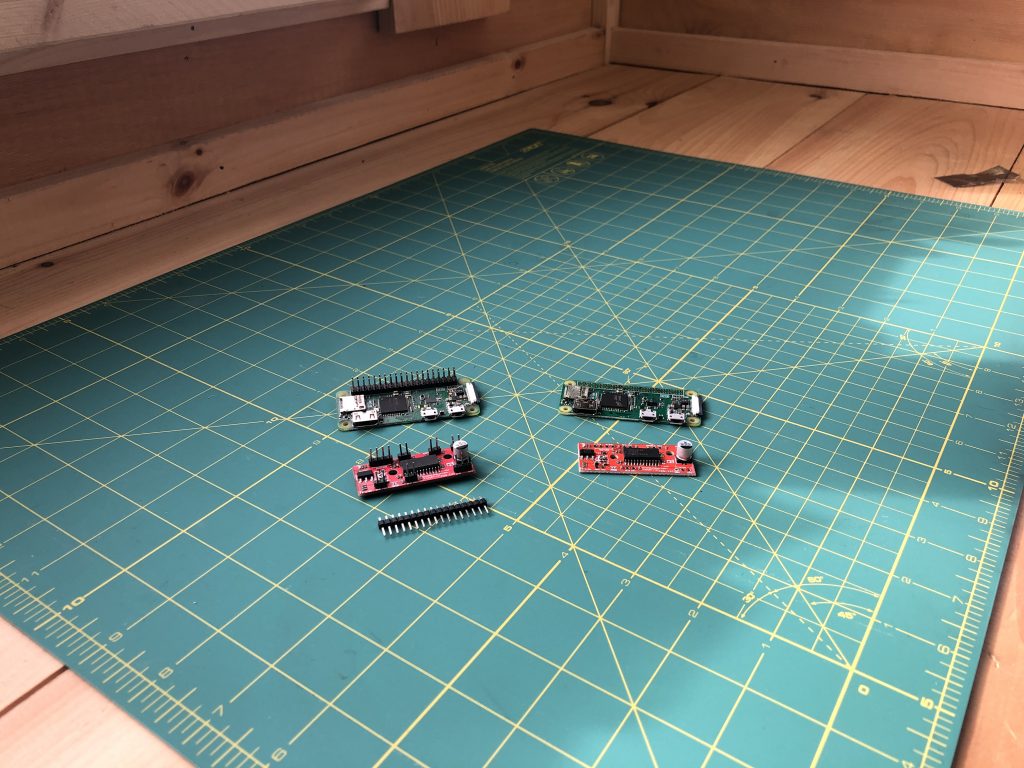

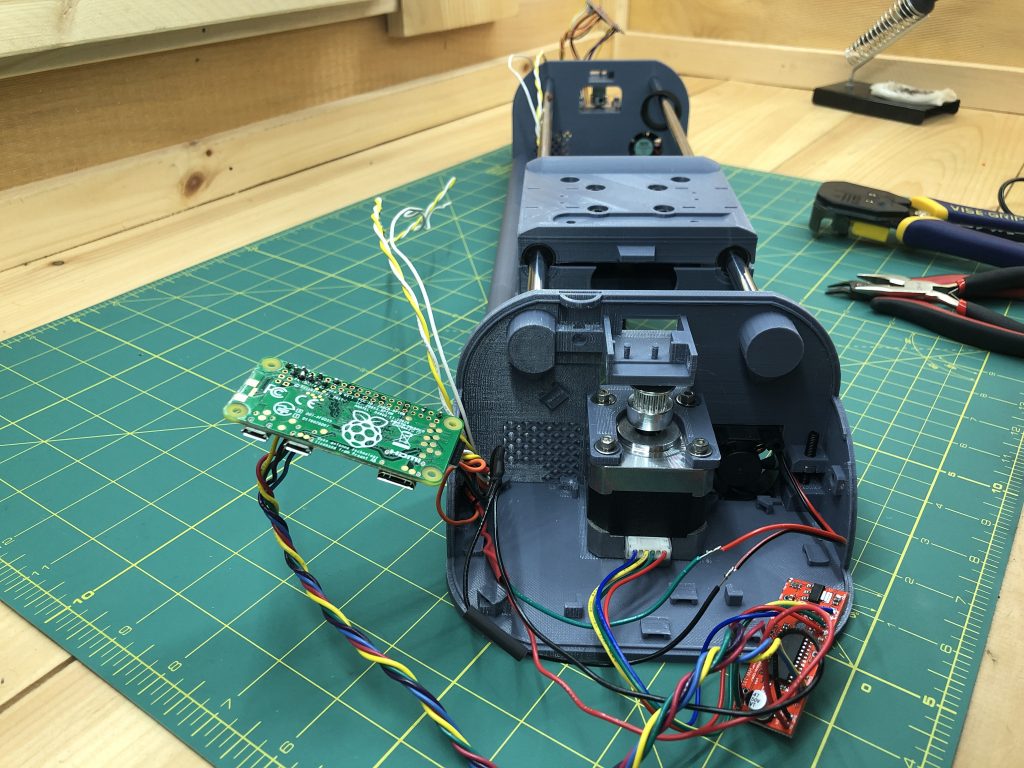

6. Raspberry Pi

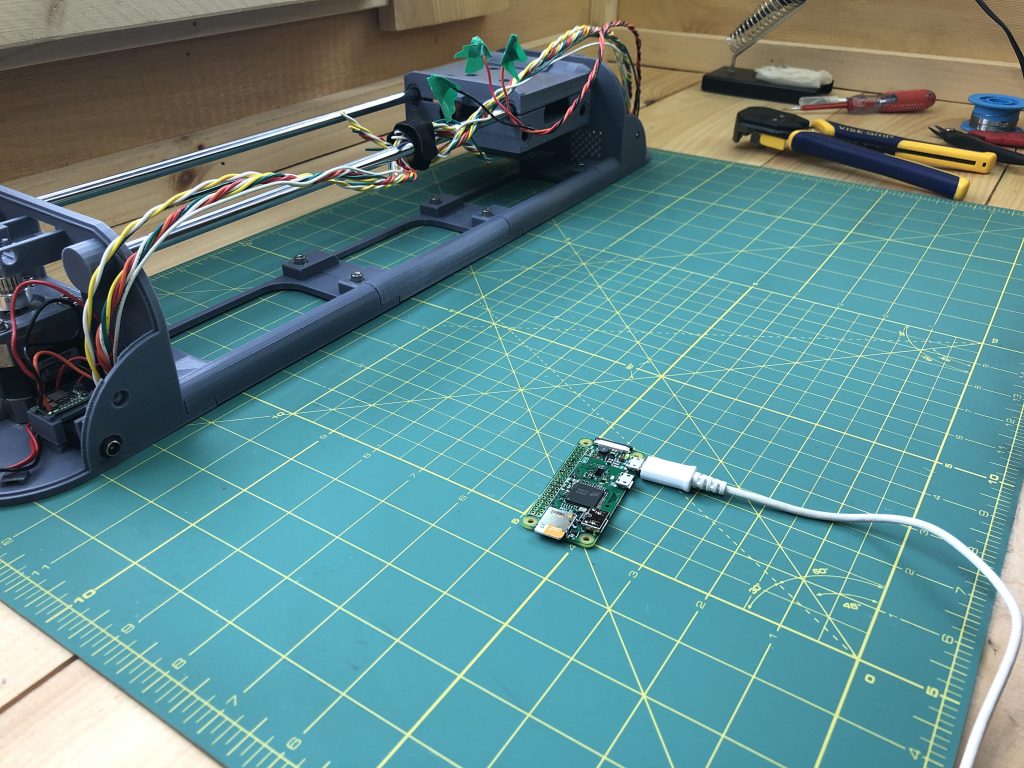

We’re going to get the Pi going so we can test components as we add them to our build (stepper motors, limit switches & servo motor).

Download the PlottyBot SD card image

Then download the Raspberry Pi Imager which we’ll use to write the image onto your SD card.

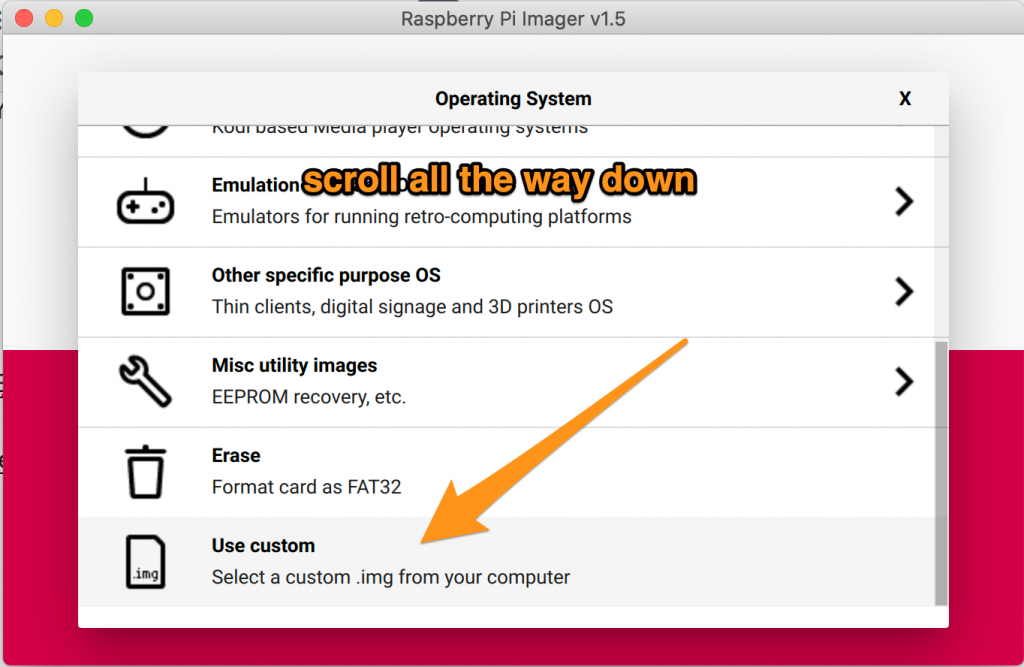

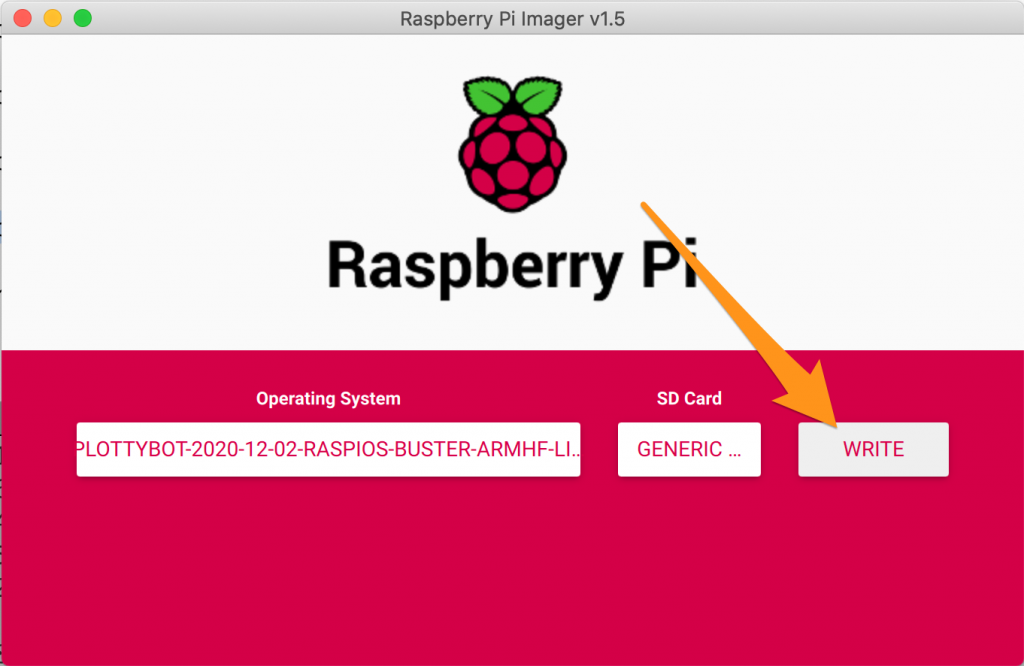

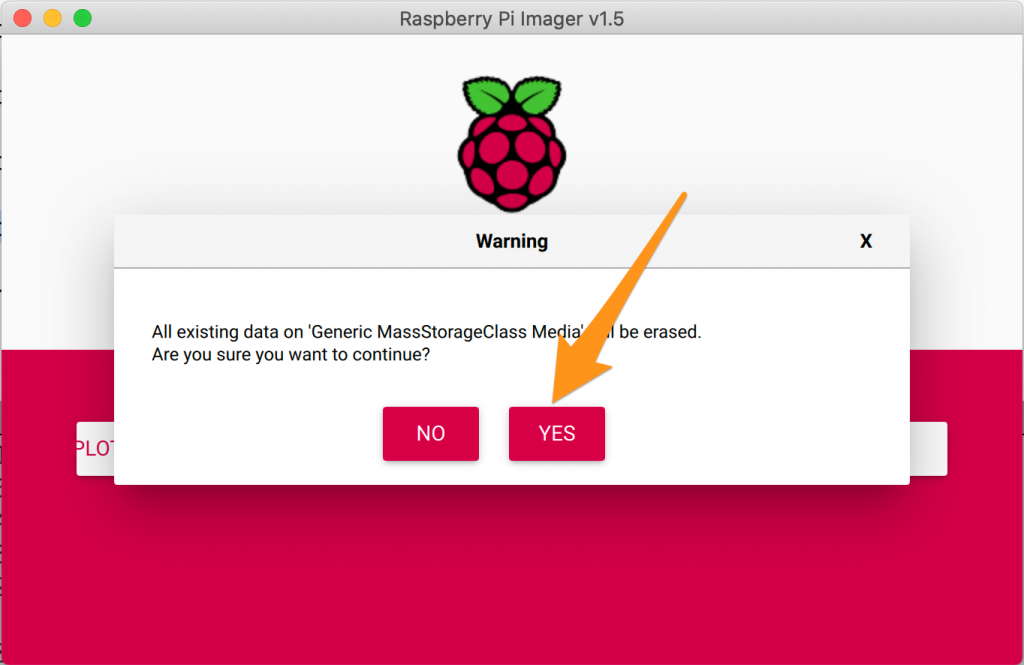

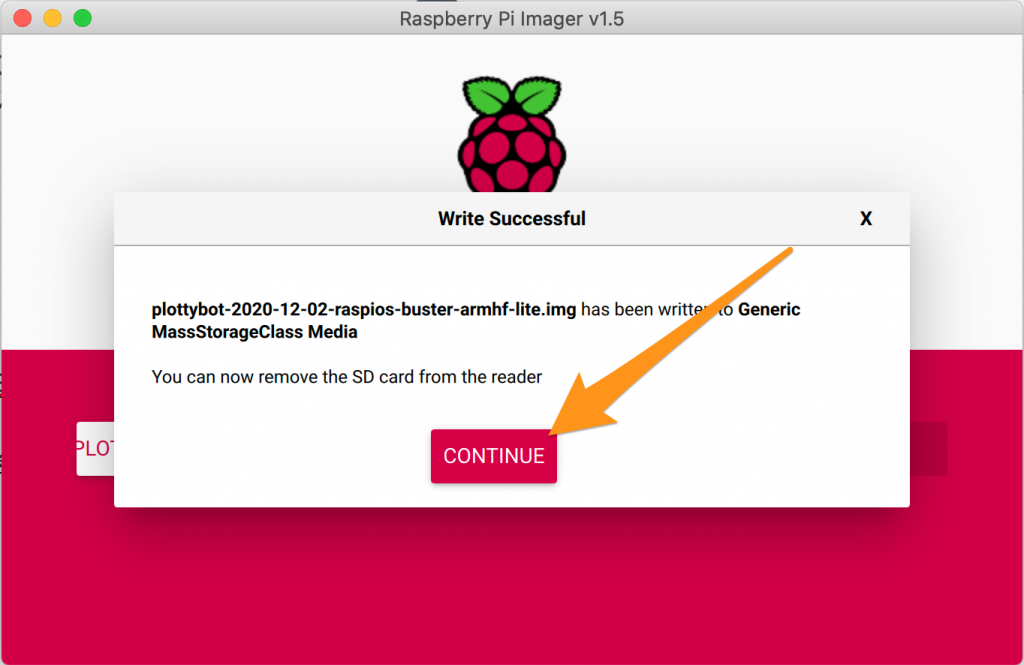

Launch the Raspberry Pi Imager and follow these steps:

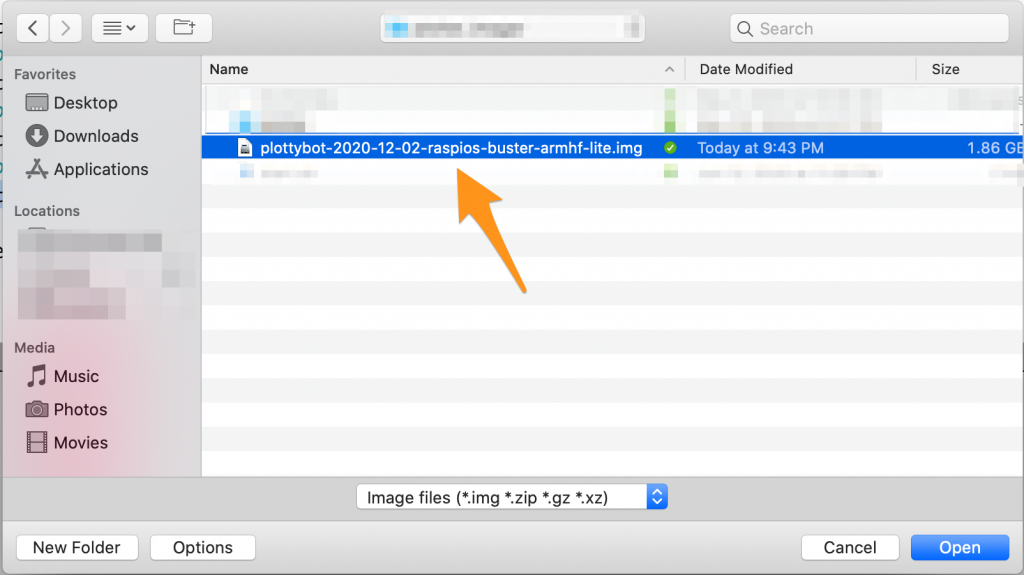

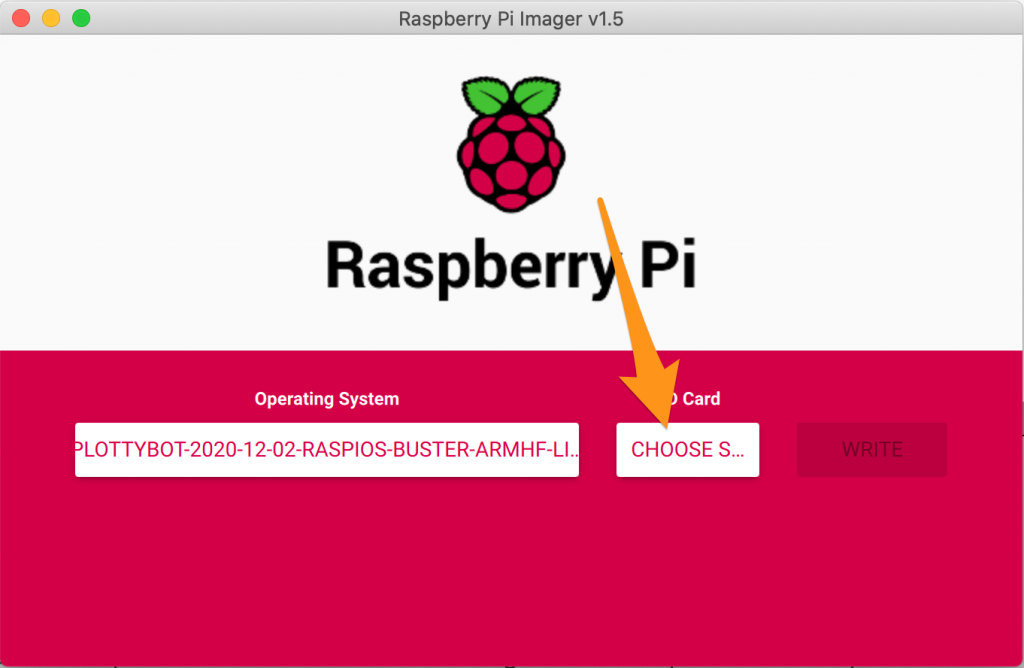

Find the PlottyBot SD card image you just downloaded.

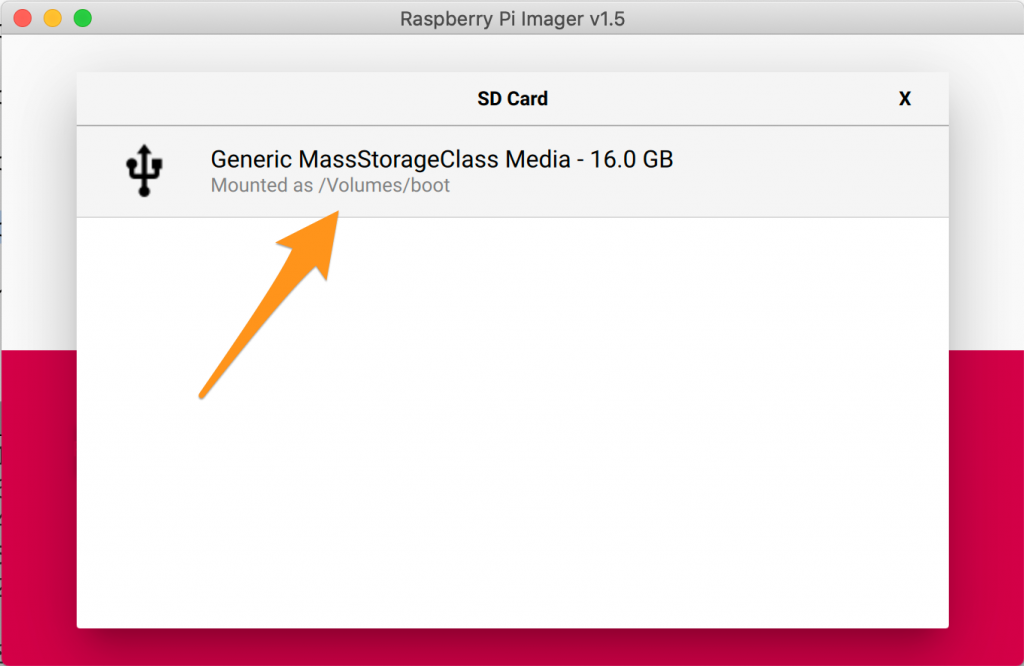

Make sure you pick the right SD card, if you have anything else show up in this list you want to triple check that you don’t overwrite something that is not the SD card for your Pi.

Elevated privileges are required.

Put the SD card in your Pi and plug it in to a standard USB power source.

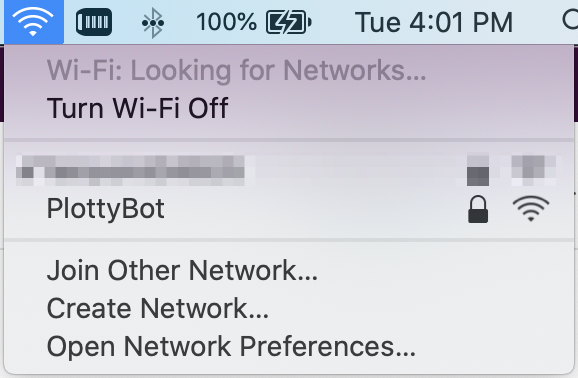

You can connect it to a screen too if you want but you don’t have to because we’ll connect to it via WiFi. Keep in mind however that the first time it boots, it will take 10 to 15 minutes to complete all the initialization steps. This is only the first time as it installs all the necessary packages to run the plotter. You’ll know it’s done when you see a new WiFi network called “PlottyBot”.

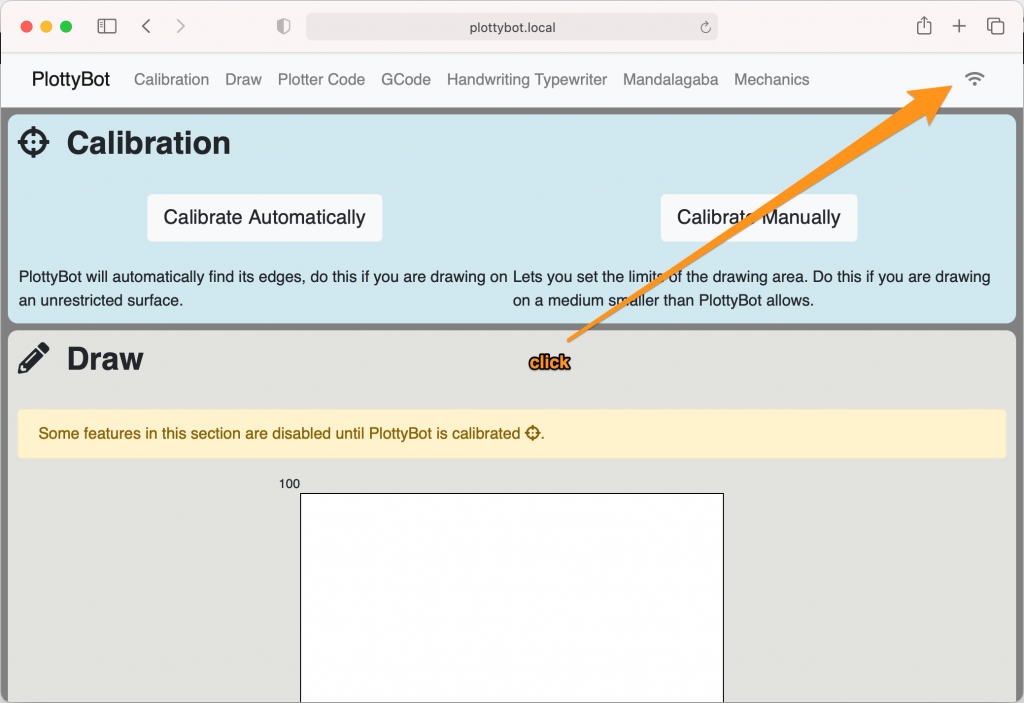

Go ahead and connect to it, the password is 1234567890 (you will no longer be connected to the internet, only to your PlottyBot). Then point your browser to http://plottybot.local. If plottybot.local doesn’t work, you can try going directly to http://10.0.0.5.

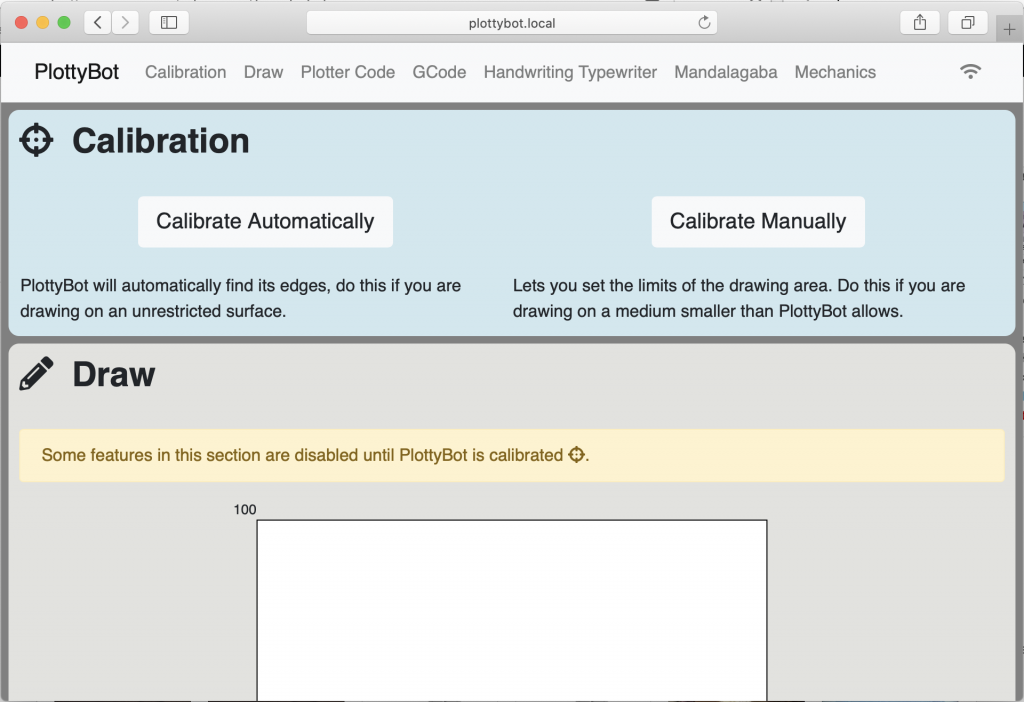

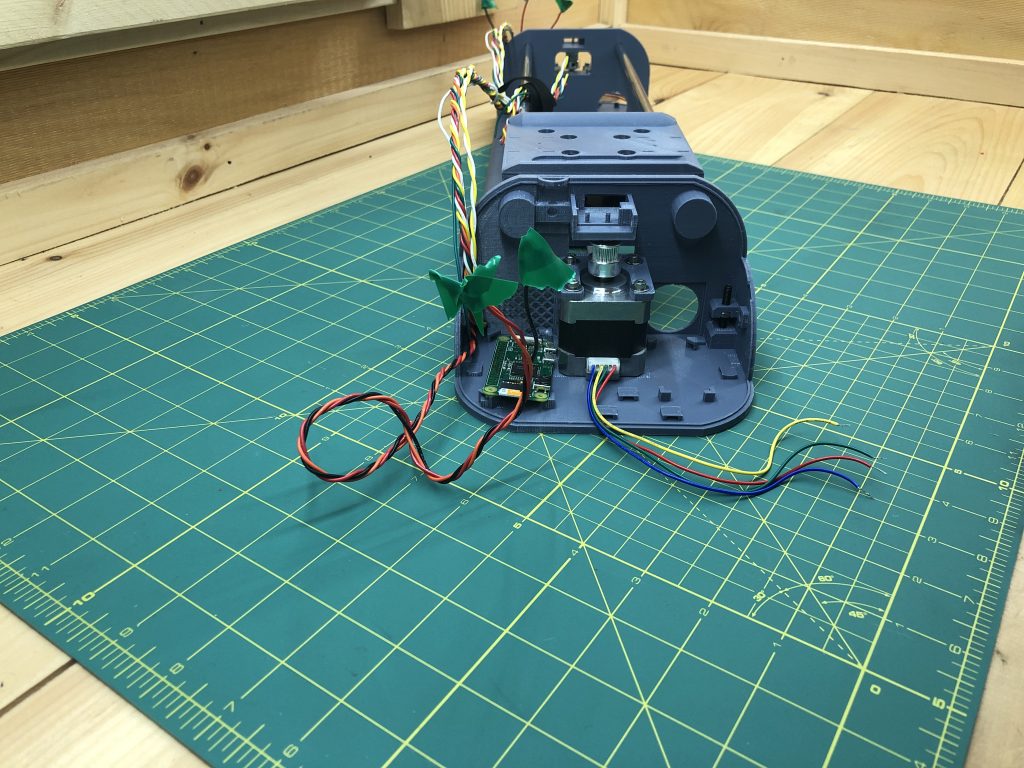

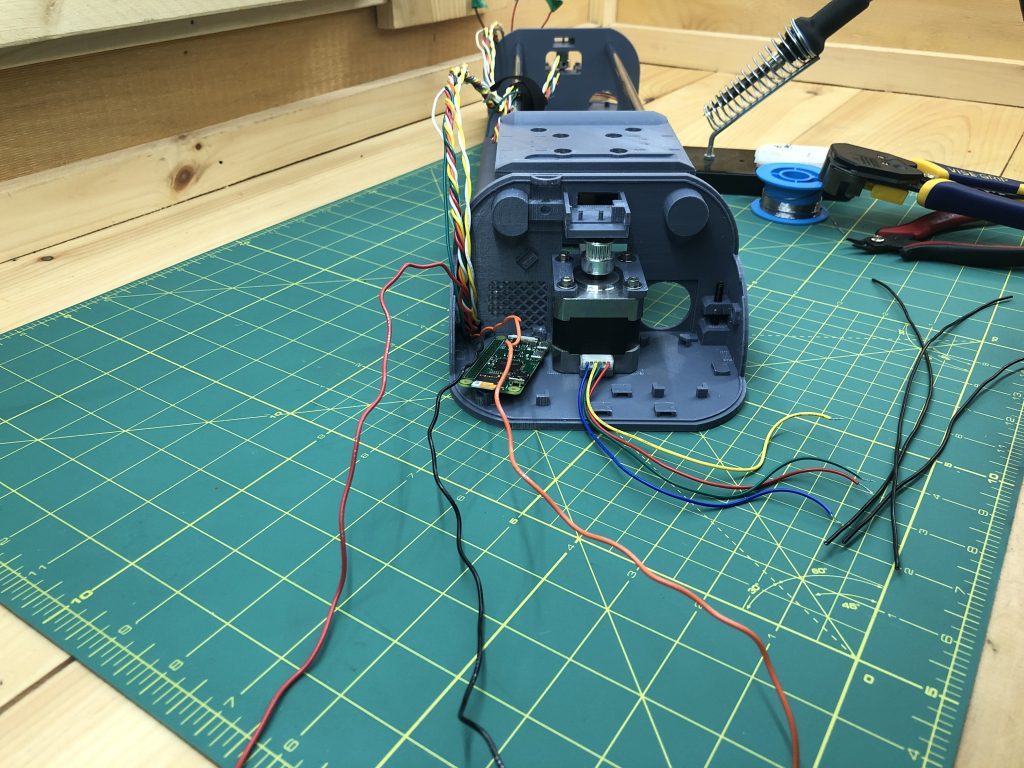

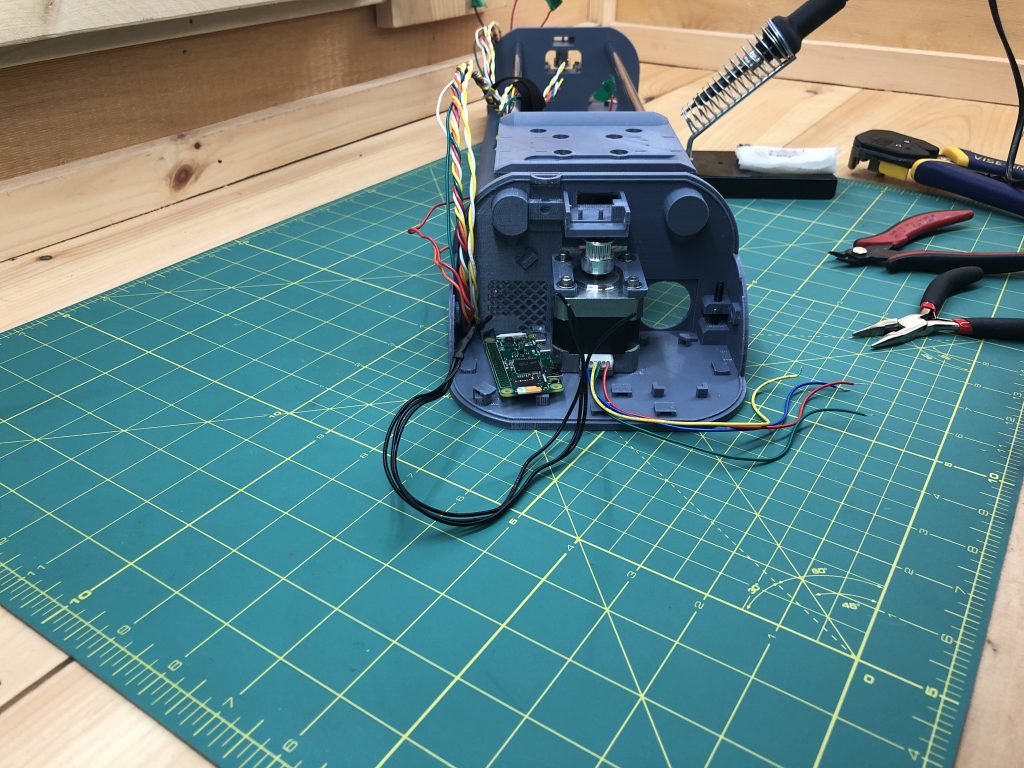

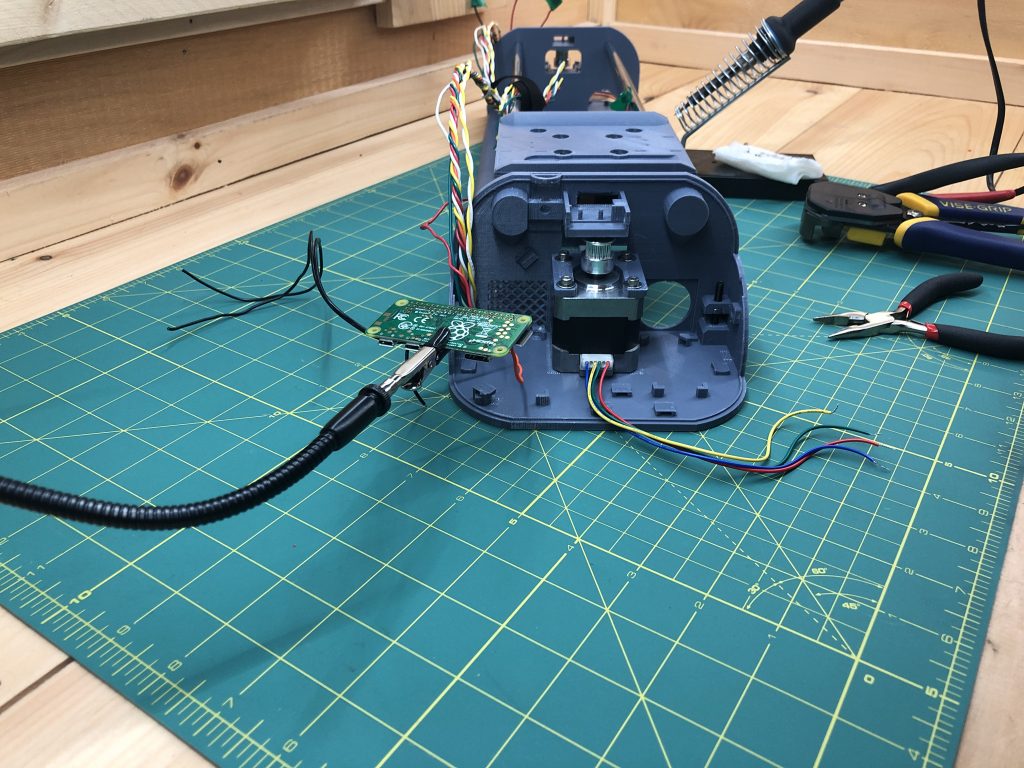

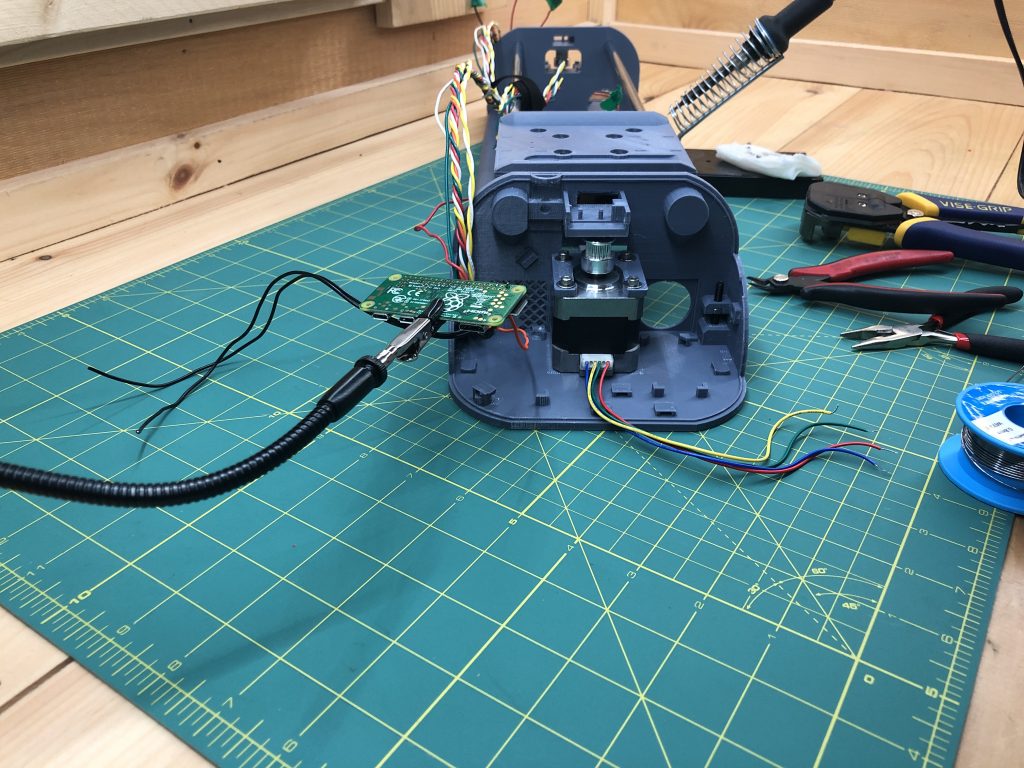

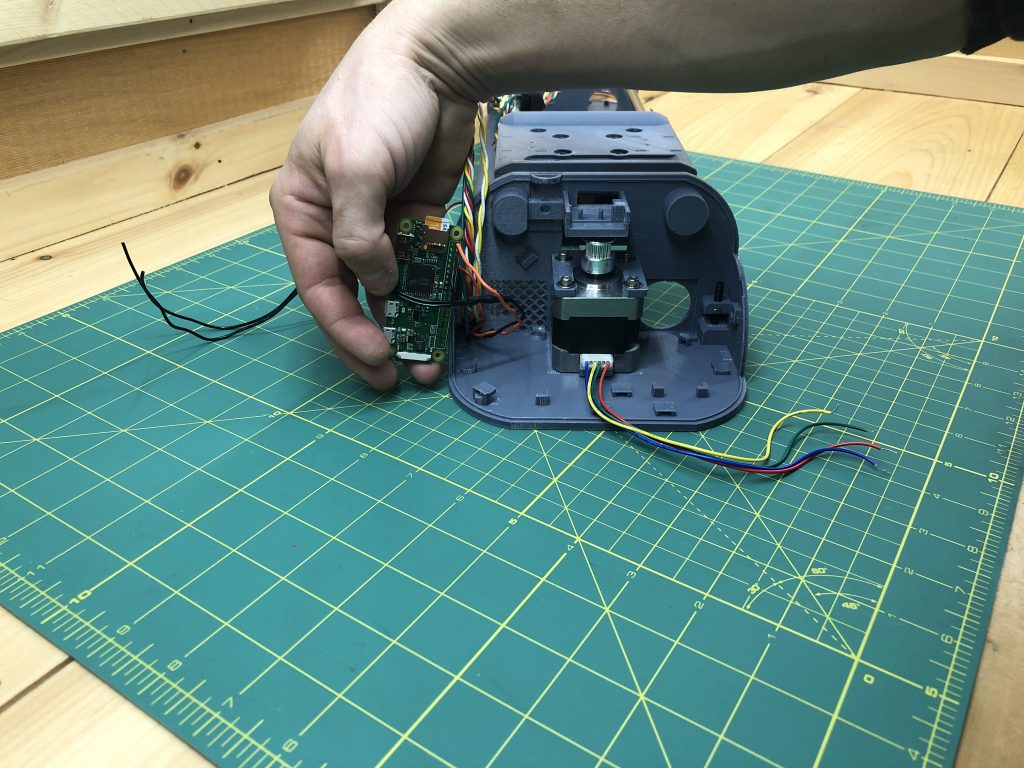

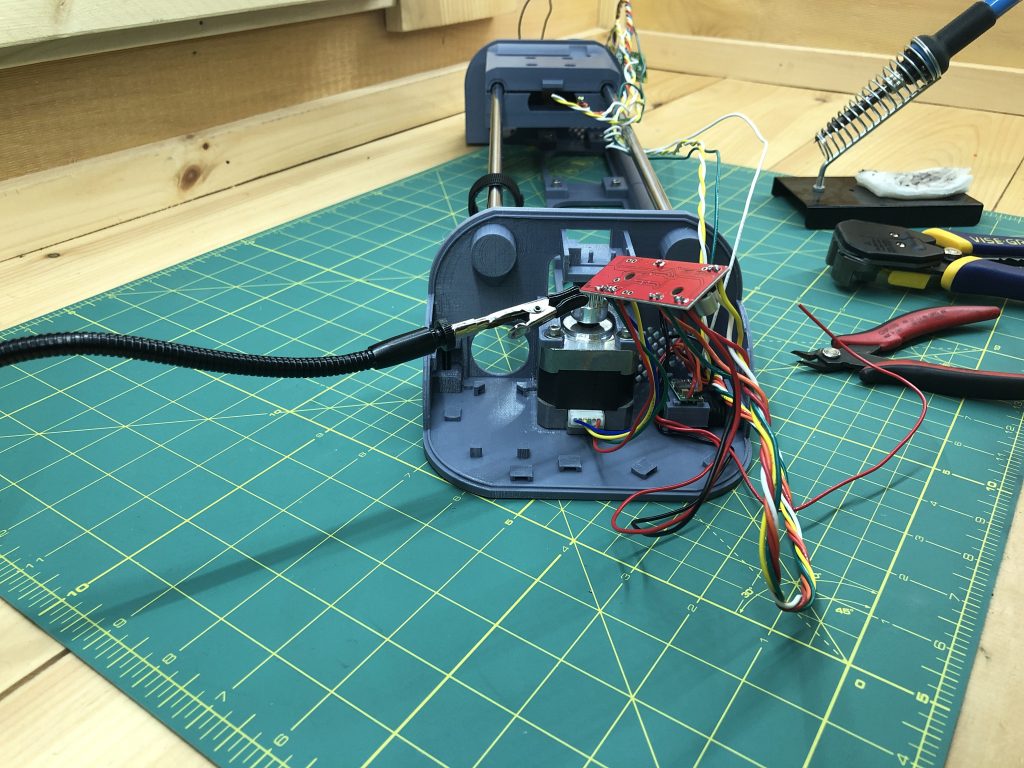

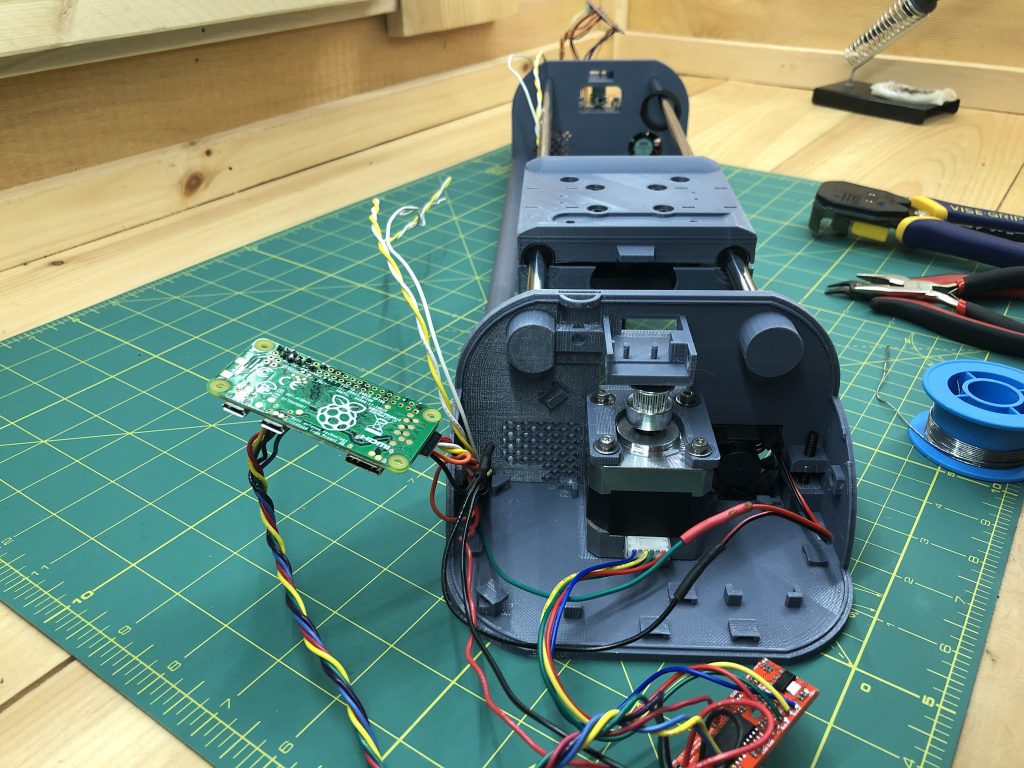

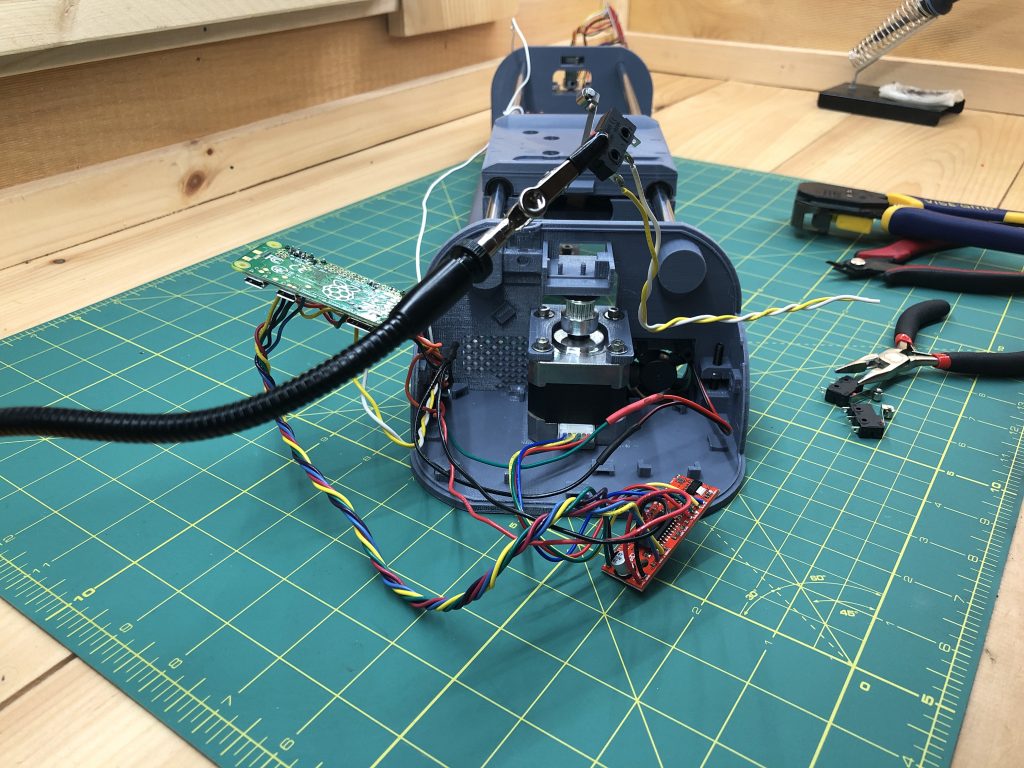

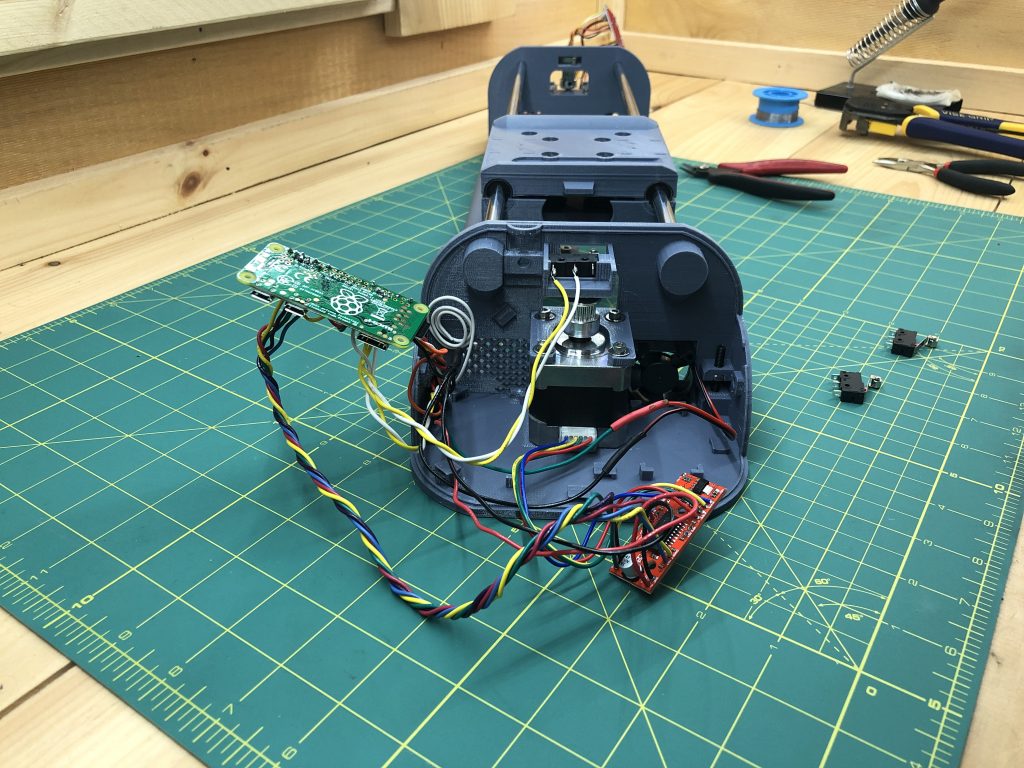

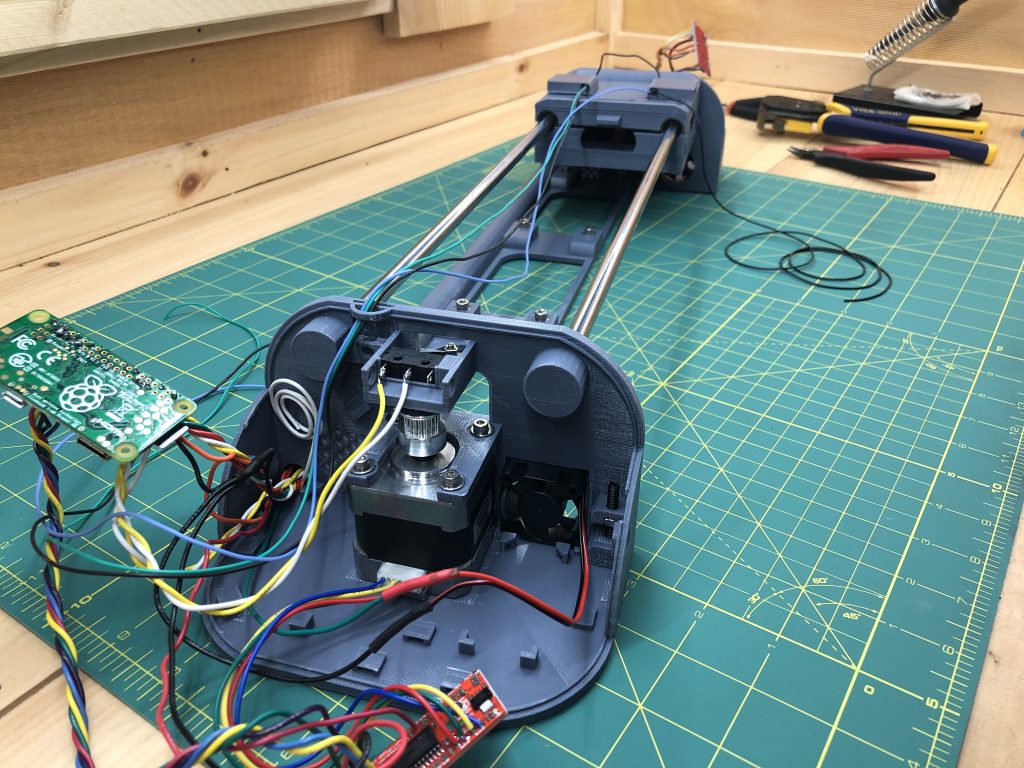

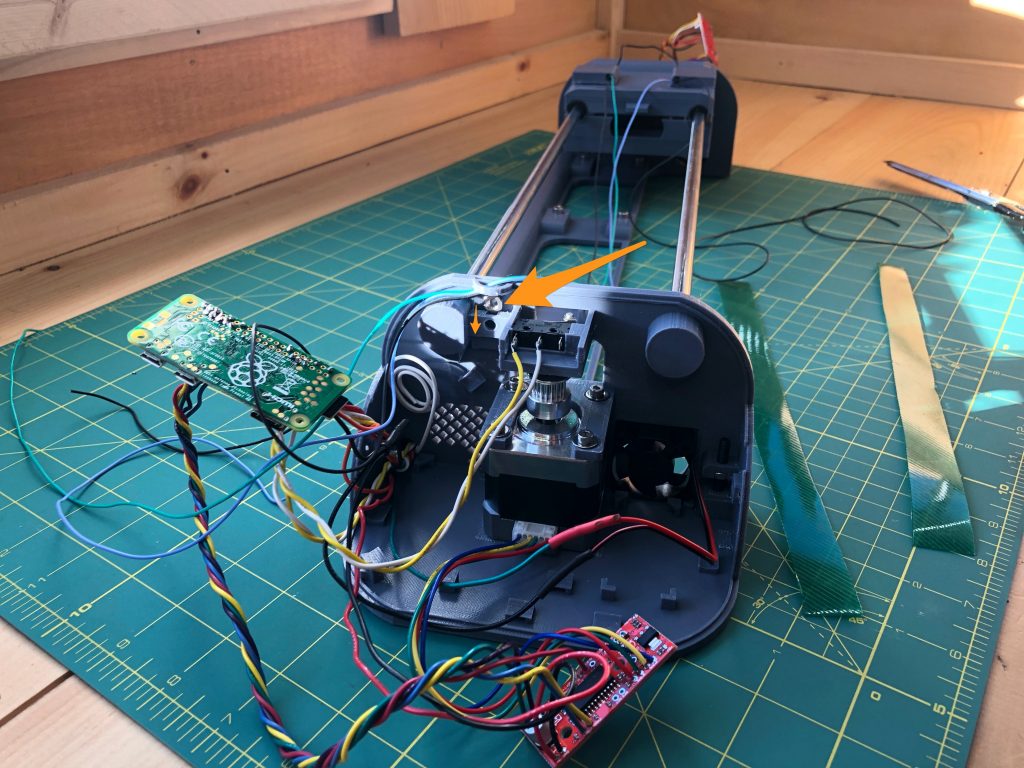

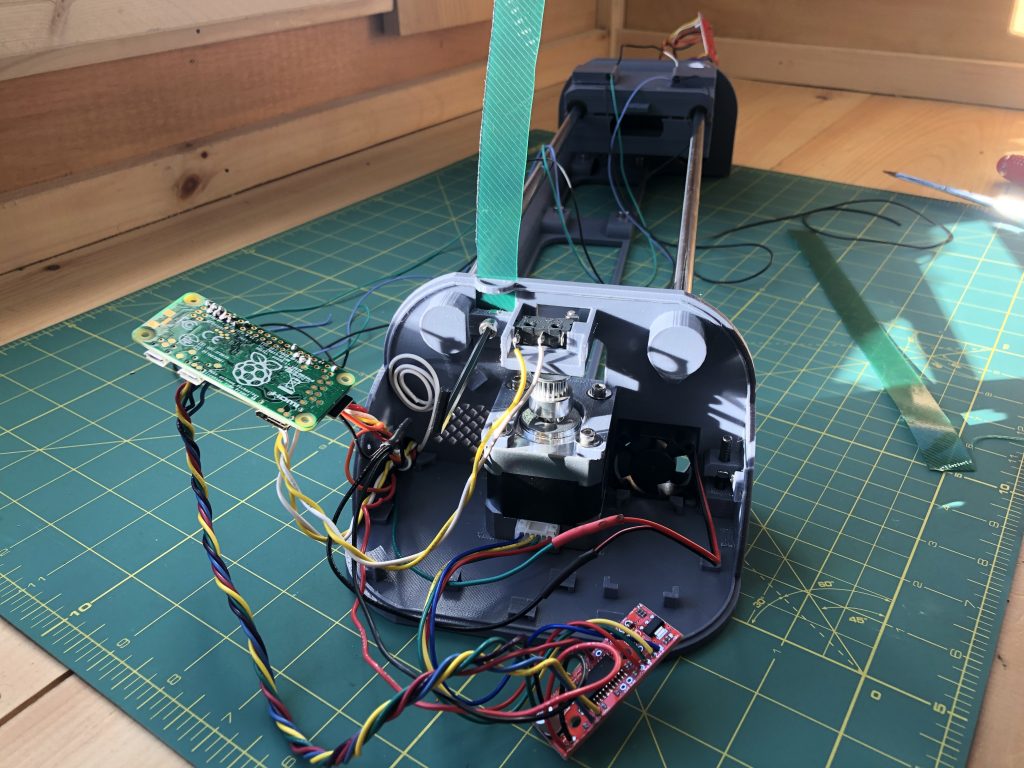

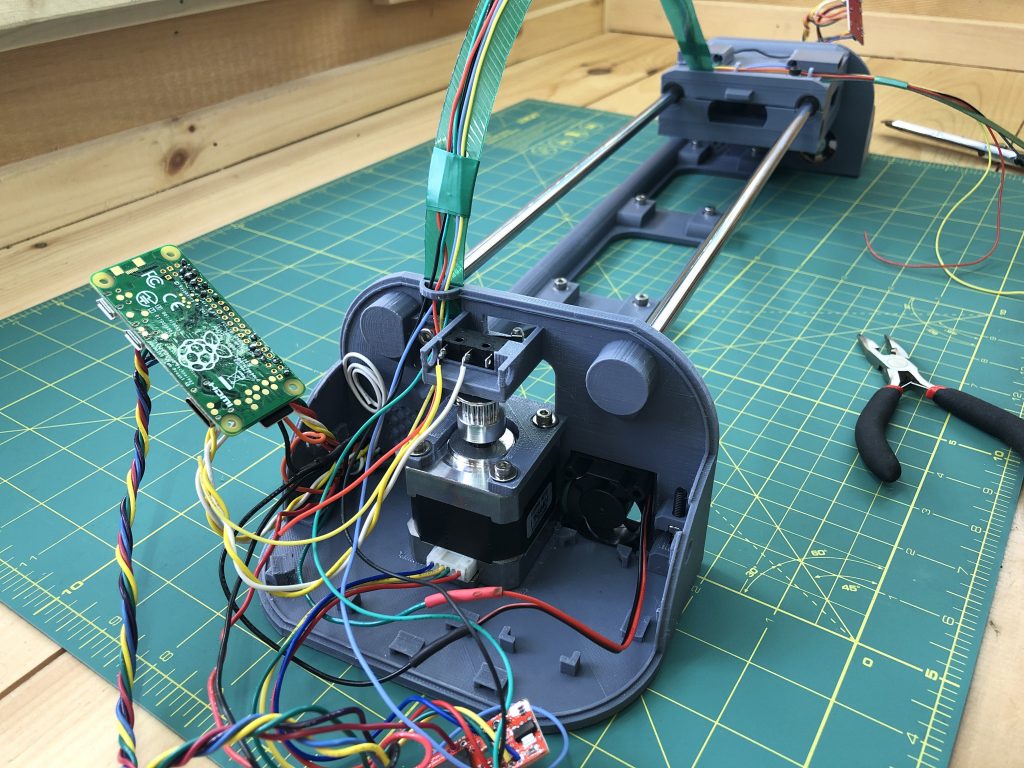

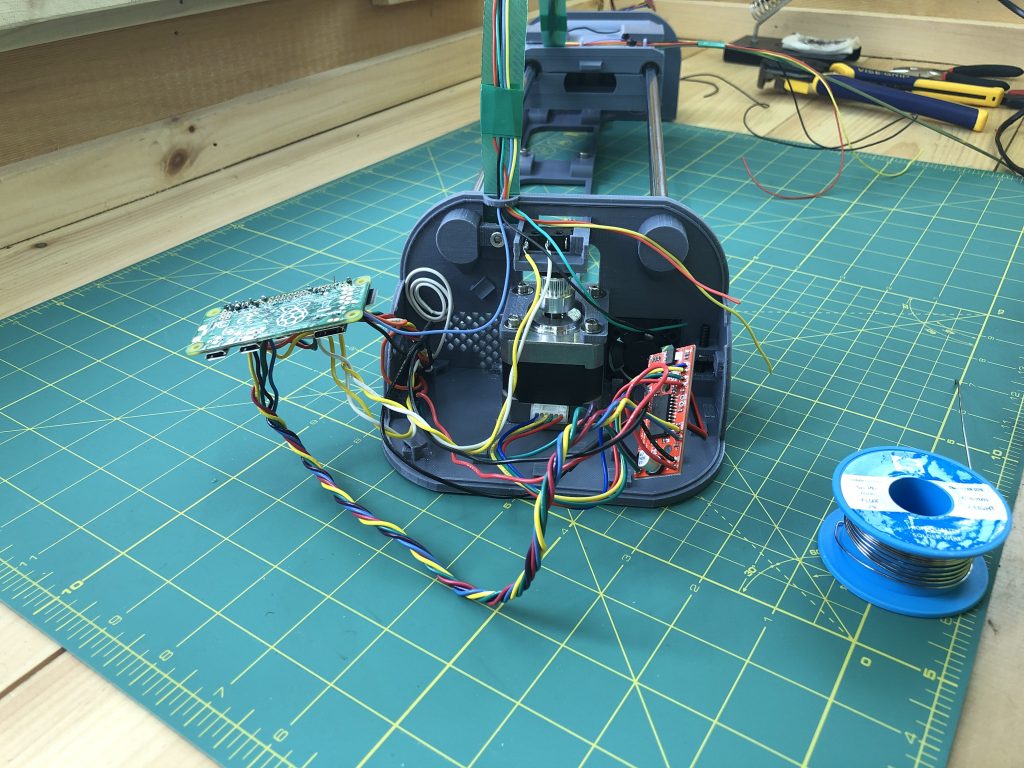

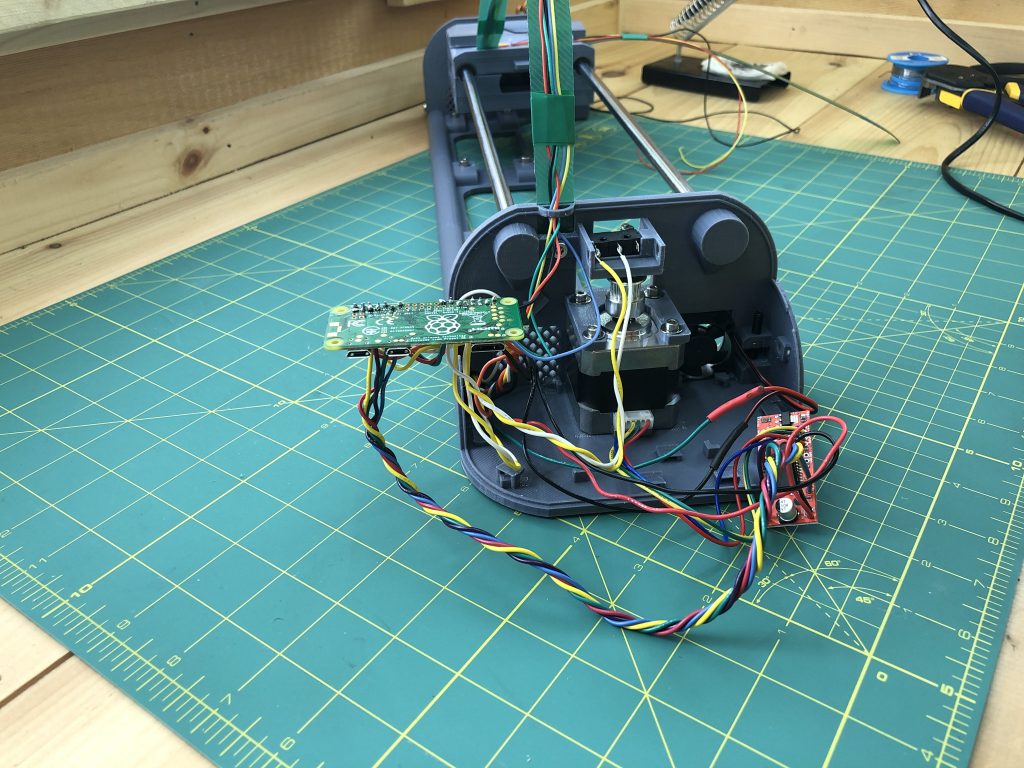

This is the web interface you will use to have your plotter do cool drawing projects for you. Because you’re seeing it, you know the Pi is ready to go in. It goes in the bottom terminal as such (here loosely fitted in its holder). Notice the red/orange/black wire bundle we’ll use to give it power.

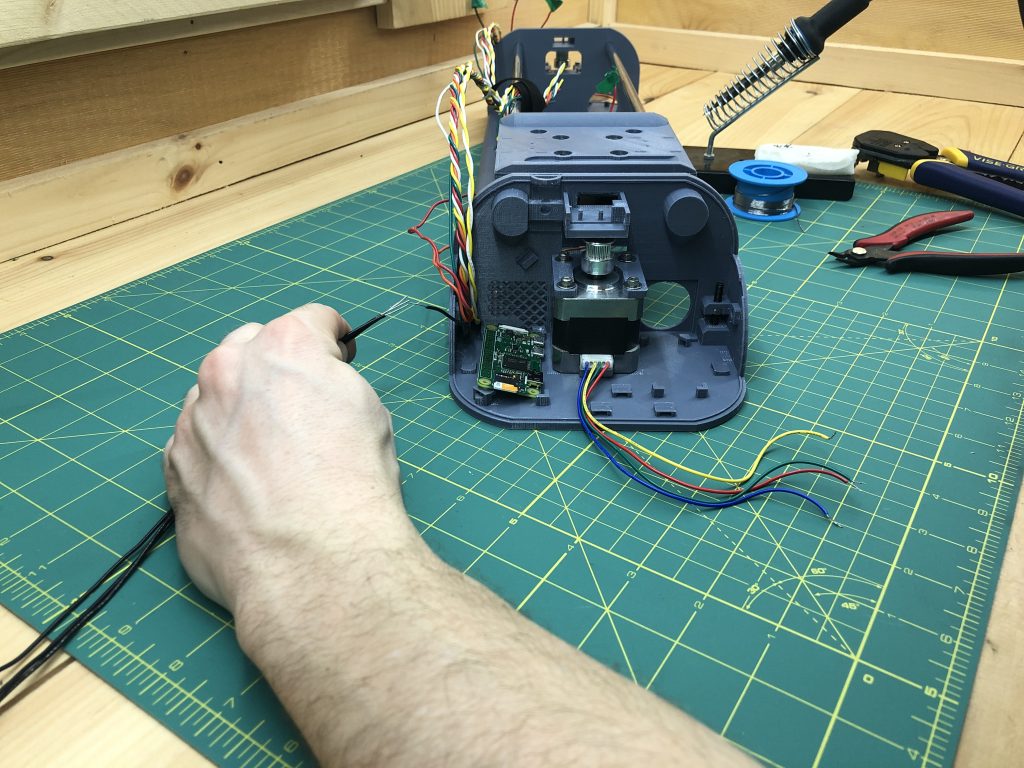

Untwist your bundle a bit to work with it.

Grab 3 new black wires long enough to reach within the bottom terminal plus some slack.

Strip them, we’ll connect them to the black wire from the red/orange/black power bundle. We want to split the black wire from the bundle into 3 for various components needing ground. You will most likely need to shorten the black wire from the bundle as it exits the “umbilical” from one terminal to the other.

Let’s solder all this so it’s nice and sturdy (notice the heat shrink tubing we’ll slide over the exposed wire later).

Then we slide the heat shrink tubing over the expose area and shrink it with heat. I use heat from the soldering iron getting it close without touching, but if you have a heat gun it’ll work better and faster. Our ground is now 3 grounds.

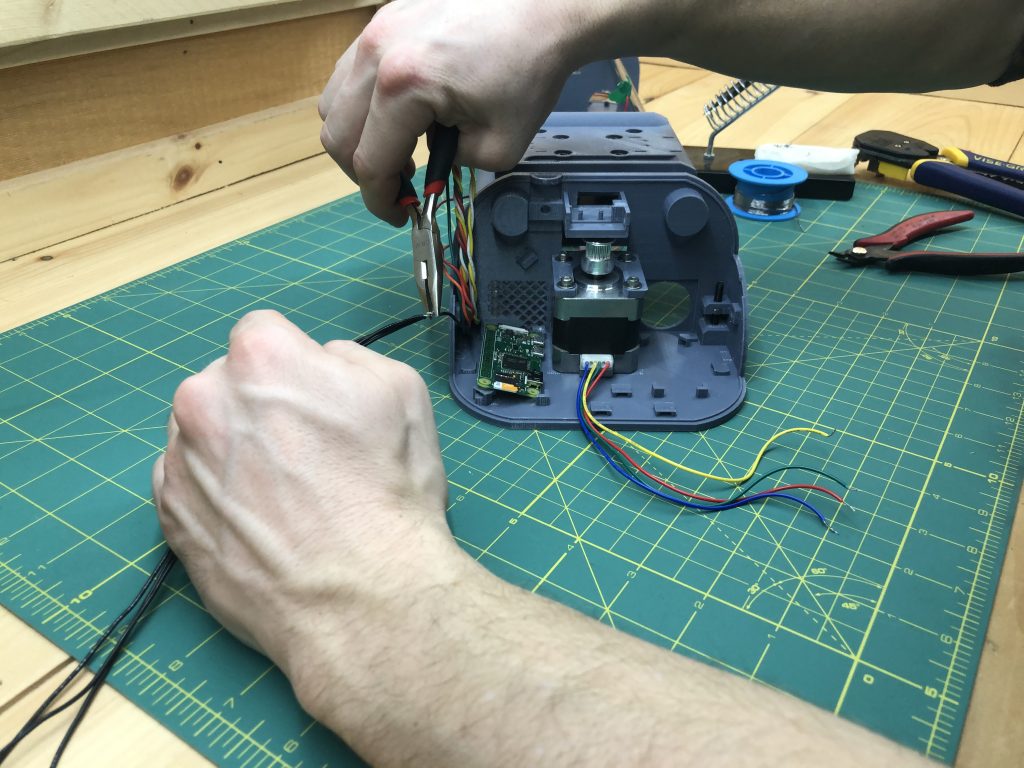

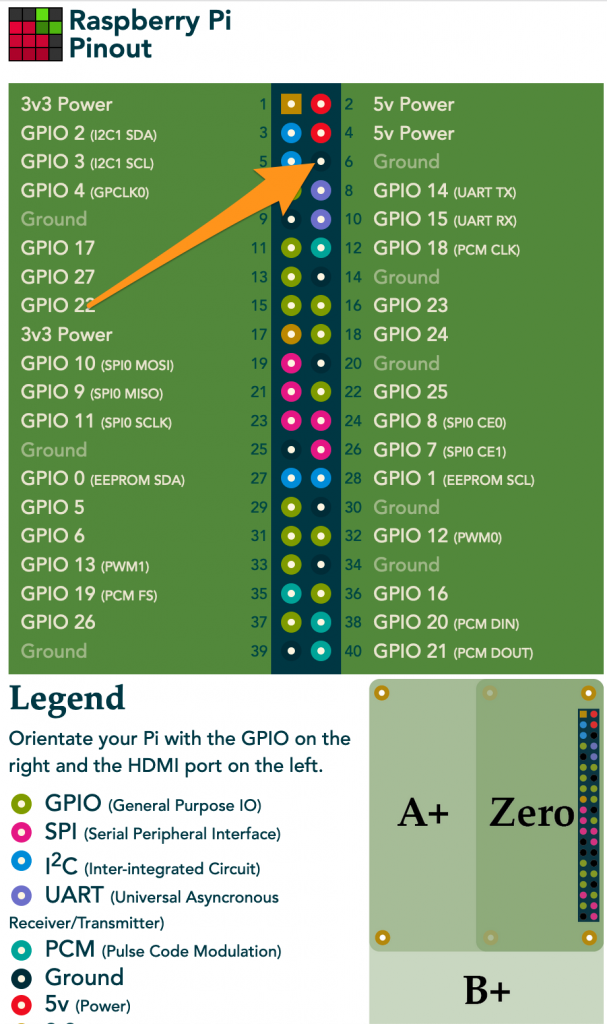

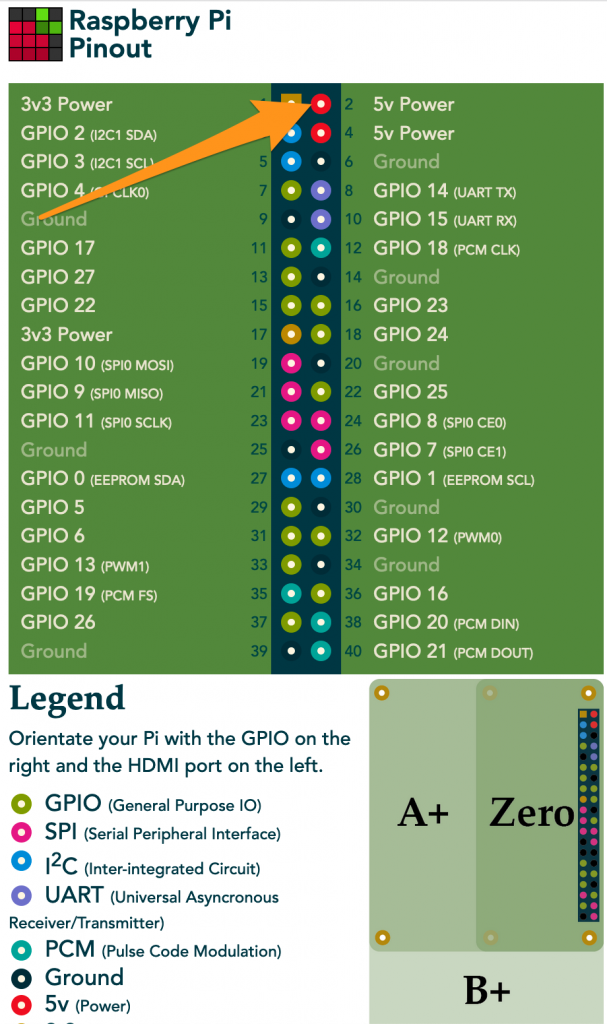

We’re about to start soldering onto the Pi. If you went with dupont connectors it’s pretty forgiving. However with soldering you want to make sure you hit the right pins. I use https://pinout.xyz as reference for Pi pins.

Solder one of the black wires you just attached to Pin #6 (Ground) of your Pi.

When soldering on the Pi (or anything really), you want to make sure you don’t create contact between pins.

Now let’s solder the orange wire from the red/orange/black power bundle to pin #2 (5V power) of the Pi. Again, you may need to shorten it from the umbilical. In the power bundle, red is 12V, orange 5V, and black ground.

You now have power from your plotter to your Pi.

Make sure that the wires have just enough slack in them to allow for the Pi to rest in its final position.

Let’s power the plotter and make sure that the Pi is itself powered. Again we know this when we see a PlottyBot WiFi network. This second boot should be much faster, maybe a minute or two.

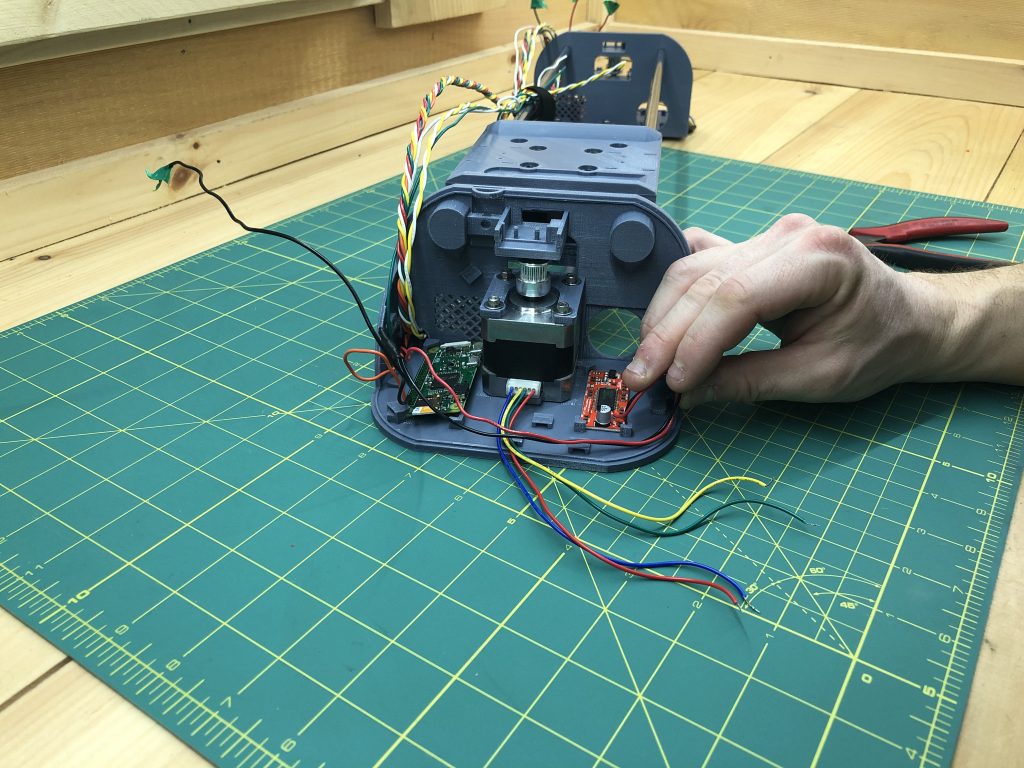

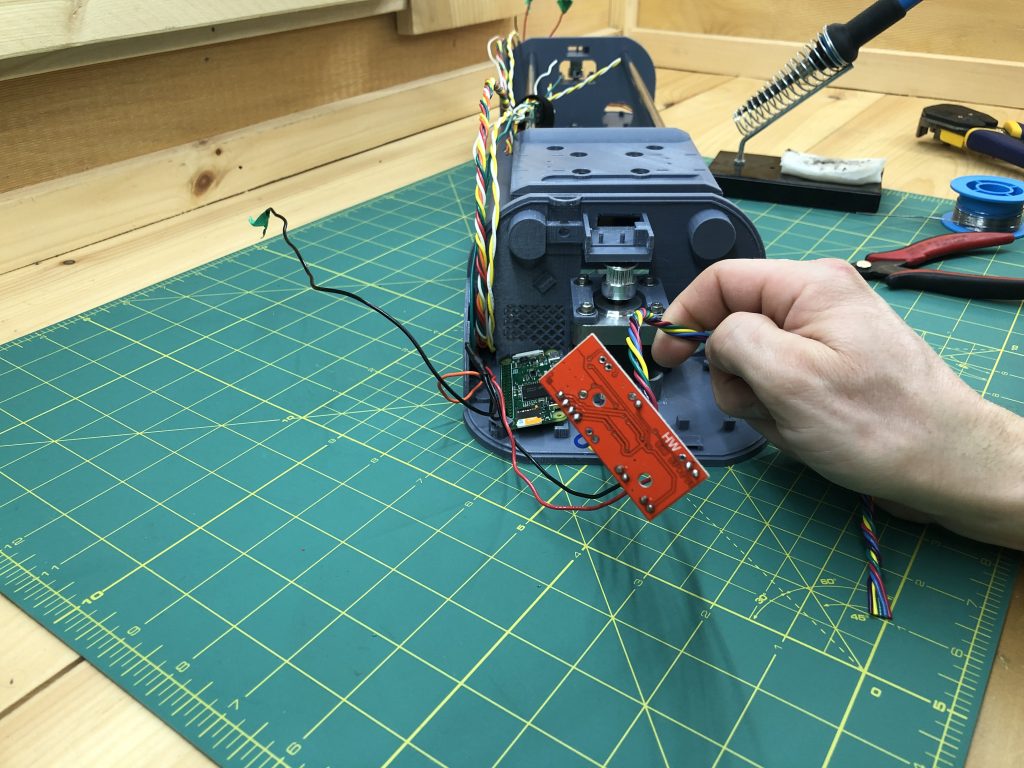

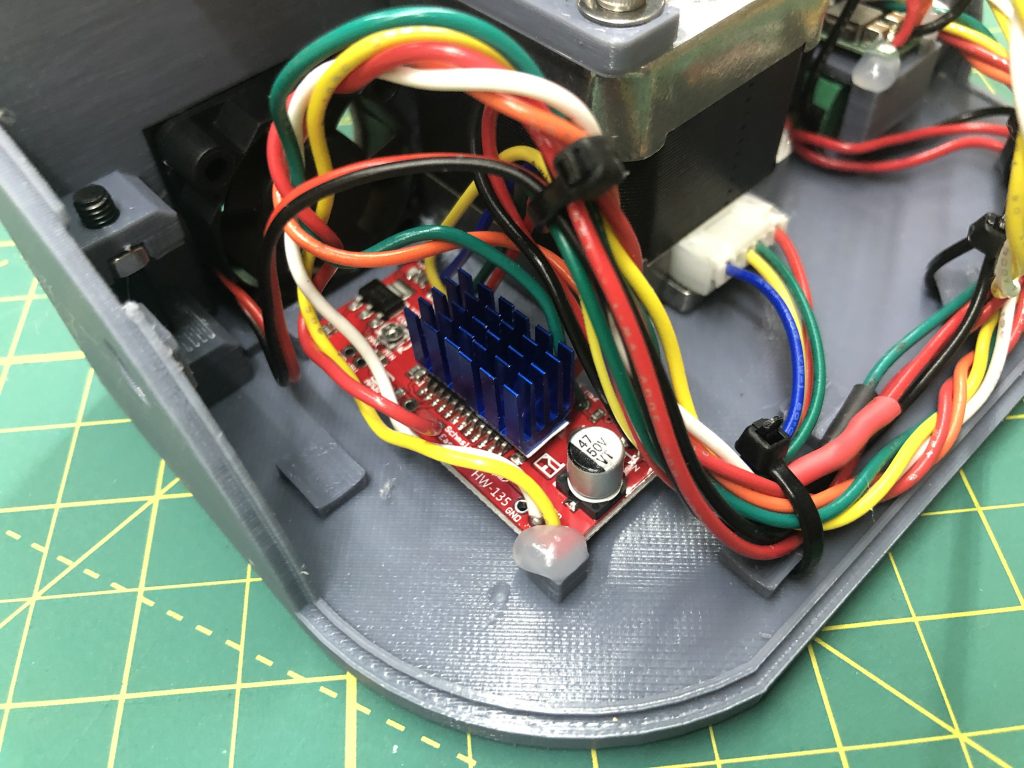

You see the PlottyBot WiFi network? Congratulations, you’ve just powered your Pi with your own power circuit. Let’s get to wiring the first stepper motor driver, the one in the bottom terminal next to the Pi. It goes in the holder on the other side. We’ll first connect power from our red/orange/black bundle. The driver takes 12V (the only red wire) and a ground (one of the 3 black wires you added). They go to the PWR IN + pin and the PWR IN GND pin on the driver respectively.

If you solder your connections, make sure that there isn’t too much wire sticking out beyond the solder blob.

The stepper motor driver’s got power.

We’ll now connect the motor itself to the driver. I’ll be a bit more expedient with the pictures by showing only the results. You can always refer to the full circuit to know which stepper motor wire goes to which pin on the driver and I recommend you do so. Essentially the other is blue/yellow/green/red going from coil A to B.

Now grab 5 wires of various colors (except black and red).

Twist them into a bundle that can reach within the terminal (plus some slack).

Connect one end of the bundle to the driver pins, we will use ENABLE, DIR, STEP, MS1 & M2. Again, the full circuit comes in handy.

Place the driver loosely in its holder.

Now we’ll connect our new twisted bundle to the Pi. Wires will be a little crazy as we move on with more components. Always make sure they can reach to where they need to go, and be ok with components “floating in the air” supported by wires you connected. Of course, if you are using dupont connectors, you can simply have components sitting in their holders and connect them as needed. The only trick is to create wires of appropriate length. The full circuit will tell you which wire of your bundle goes to which pin of you Pi.

To confirm:

Pi pin #37 (GPIO 26) goes to driver ENABLE

Pi pin #35 (GPIO 19) goes to driver STEP

Pi pin #33 (GPIO 13) goes to driver DIR

Pi pin #31 (GPIO 6) goes to driver MS1

Pi pin #29 (GPIO 5) goes to driver MS2

When all the driver wires are connected, let’s power the plotter once more. Connect to the PlottyBot WiFi network, point your browser to http://plottybot.local and let’s see if the bottom stepper will move.

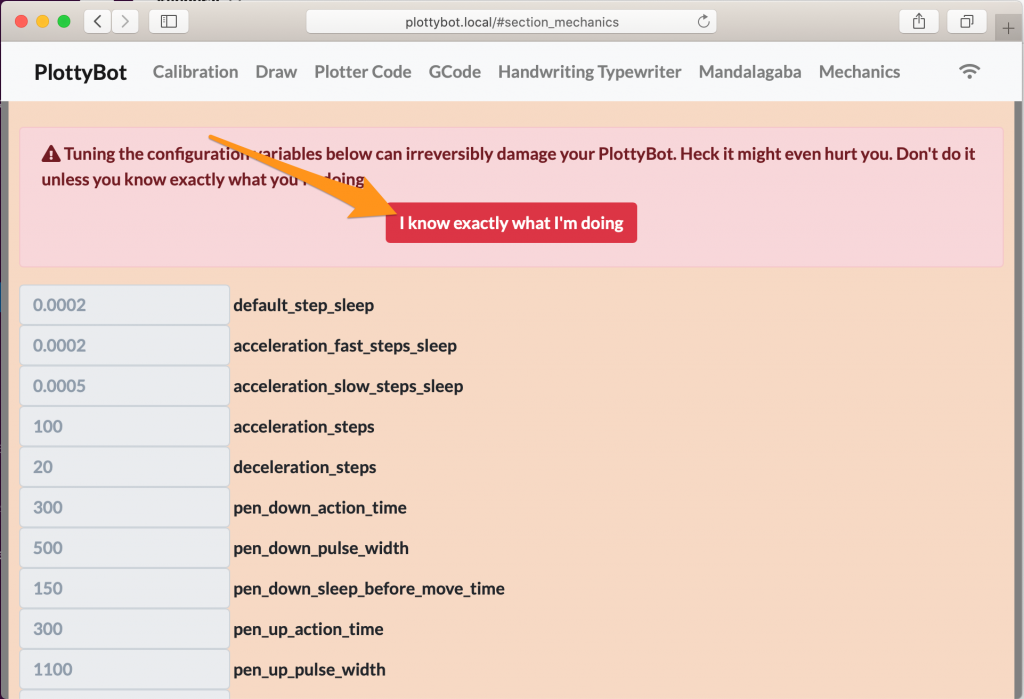

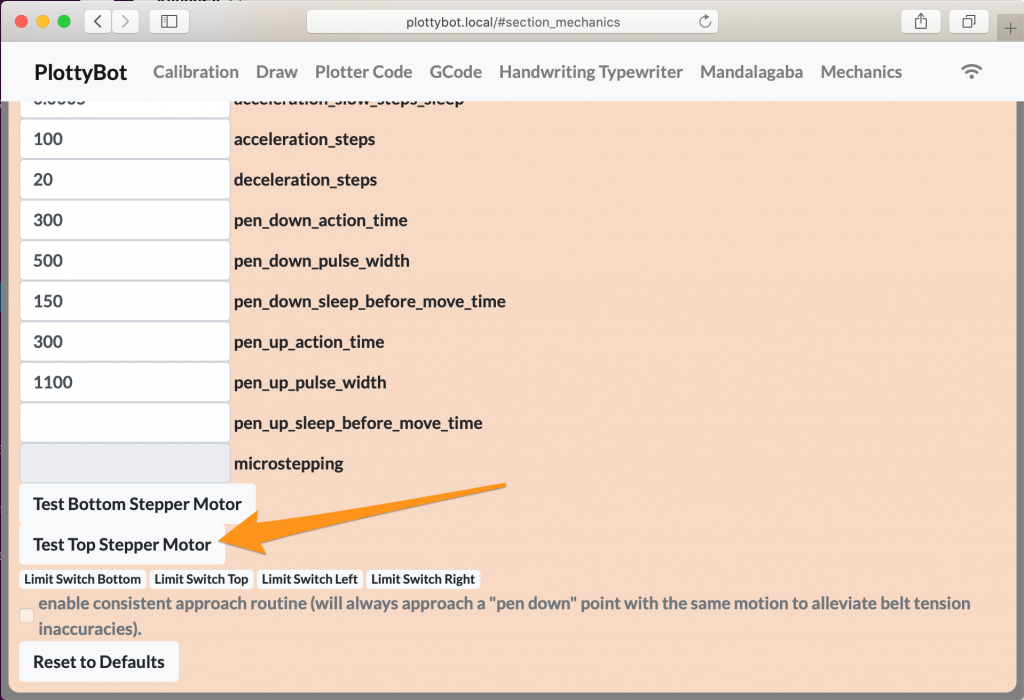

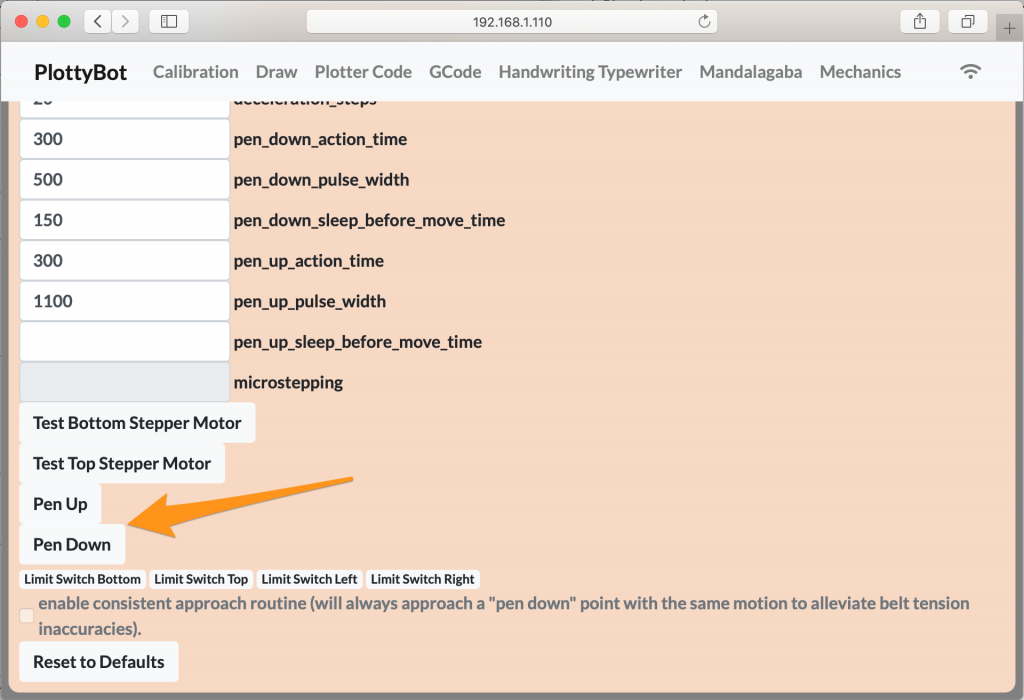

Scroll down to the “Mechanics” section of the web interface. This section is only enabled if you know what you’re doing.

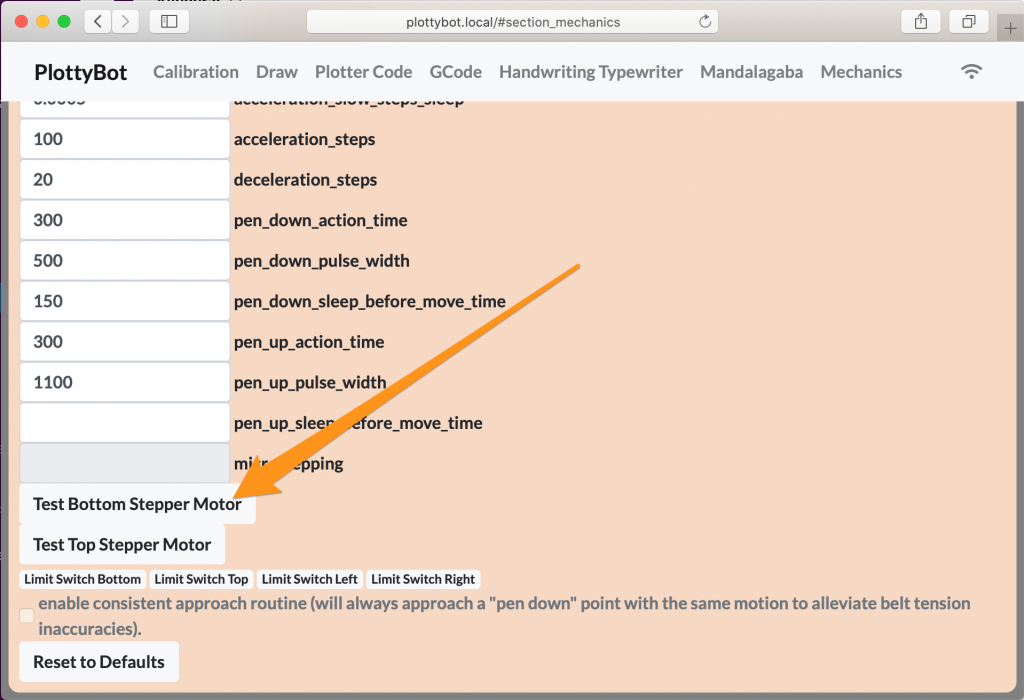

Click on “Test Bottom Stepper Motor”.

Your bottom stepper should move back and forth 4 times with a different sound pitch every time. What’s going on is that it’s instructed to rotate a certain amount at various levels of microstepping. If you don’t see this behavior, one of the wires from the Pi to the driver is misconnected, or the driver is bad. Remedies are case by case and will trying various scenarios to isolate the issue. Drop a comment if you’re stuck.

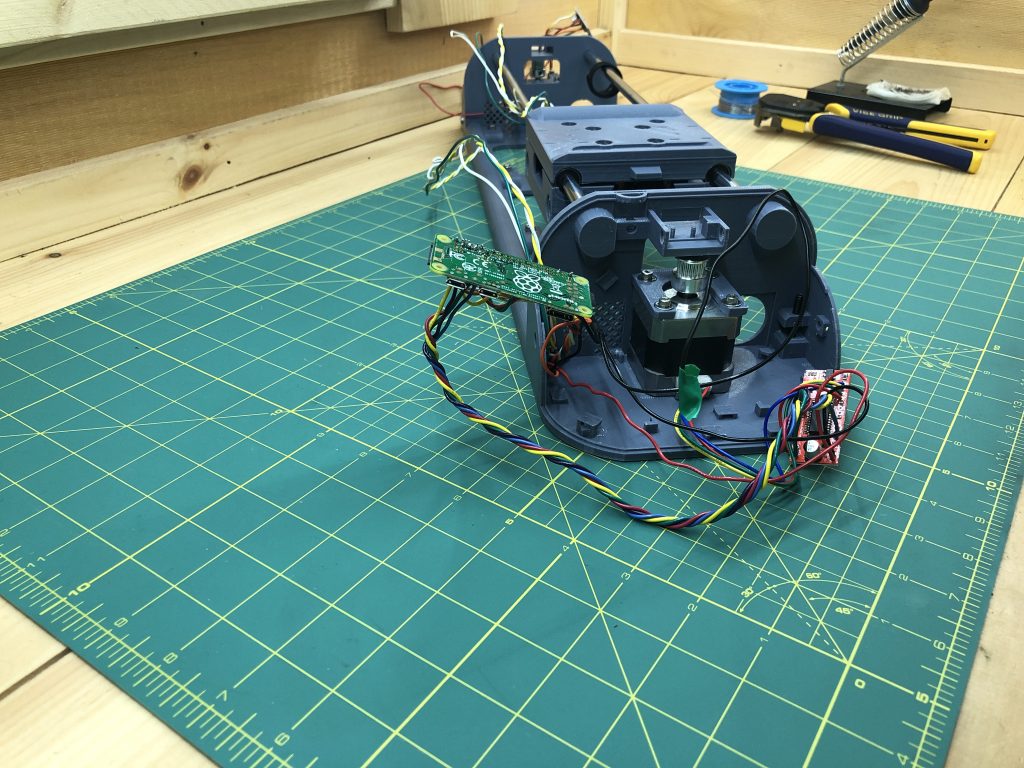

Let’s now wire up the top terminal’s stepper motor. Remember how we bundled 5 wires going from the terminal where the Pi resides (bottom) to the terminal where the power resides (top)? Well this bundle is meant for the top terminal stepper driver.

Going quick because we’ve already done this on the other side. Grab a red wire and a black wire from the power outlet and connect them to the stepper driver’s PWR IN + and PWR IN GND pins as you’ve done on the other terminal. Also connect the terminal’s stepper motor coils as you have done before. And finally, connect the 5 wire bundle to it. On the other side of the plotter, this 5 wire bundle goes to the Pi and will join:

Pi pin #40 (GPIO 21) goes to driver ENABLE

Pi pin #38 (GPIO 20) goes to driver STEP

Pi pin #36 (GPIO 16) goes to driver DIR

Pi pin #32 (GPIO 12) goes to driver MS1

Pi pin #28 (GPIO 1) goes to driver MS2

On the other side of the plotter:

Power the plotter once more, connect to wifi, go to the web interface and into the “Mechanics” section. Click the “Test Top Stepper Motor” button this time.

Once again you’ll see the motor move 4 times the same way, but with various sounds.

Once again if you don’t, you’ll want to investigate and isolate the issue.

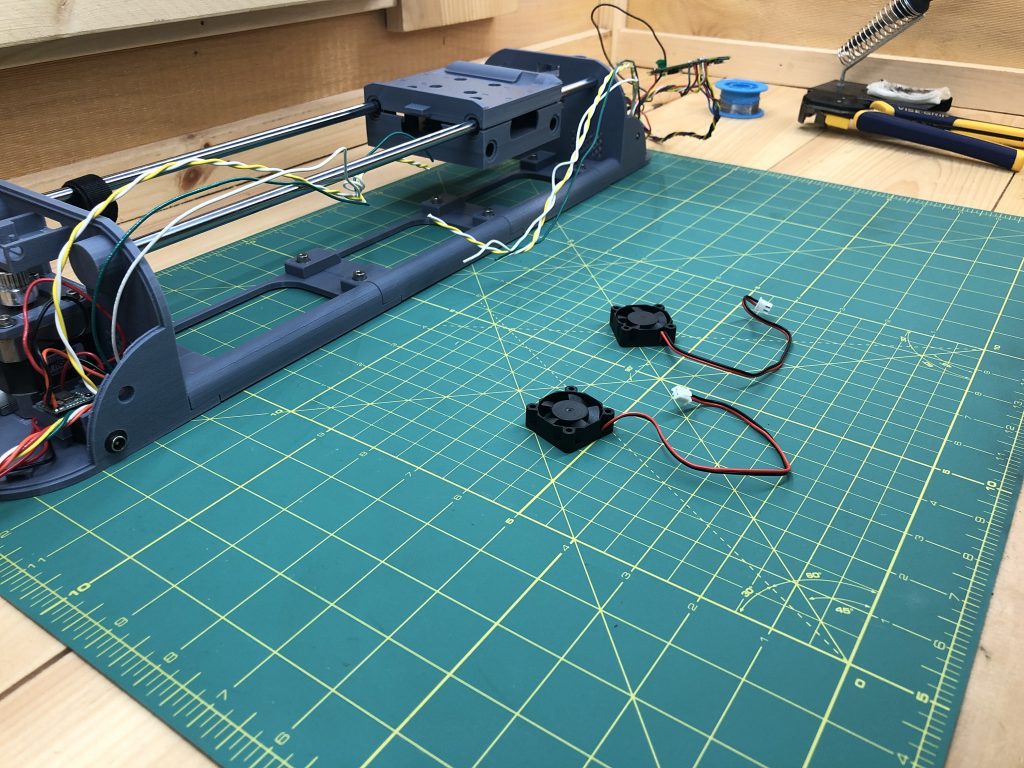

7. Fans

Electrical:

2 fan

The fans are wired in series and not tied to the Pi, they just spin when the plotter is powered.

Start with the top terminal (where power is), the fan will pressure fit in the driver corner. The stepper driver can get hot which is why we give give it good airflow, we’ll also give it heat sinks later on. These fans have a slightly different width and height so make sure it goes in at the right orientation. You can then connect a red wire from the red/orange/black power bundle. Do not however connect the black side, because they are wired in series, we’ll instead use one of the standalone wire we have in the umbilical.

Then with heat shrink tube.

On the other side of the plotter (bottom), we connect the standalone wire from the umbilical to the red (positive) wire of the other fan. Its black (ground) side goes to one of the power bundle’s black wire. Again, the fans are connected in series.

Now with heat shrink tubes.

You can power the plotter again to make sure both fans are spinning.

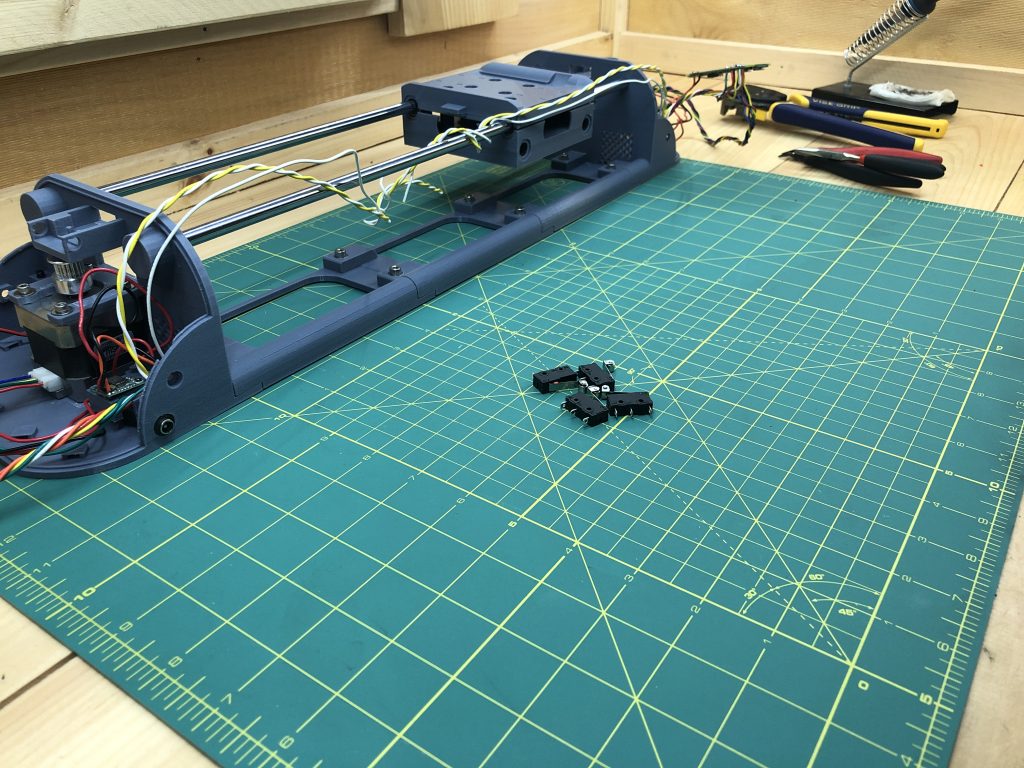

8. Limit Switches

Hardware:

1 M4x8 hex screw

1 M4 nut

2 M4x40 hex screw

2 M4x35 hex screw

4 M4 lock nuts

8 washers

3D printed:

gondola_top_screw_cover_x4

gondola_top_limit_switch_cap_x2

gondola_top_cable_management_x1

Electrical:

4 limit switch

wires

At the top terminal, put a limit switch in its enclosure. Run the yellow/white bundle from the umbilical to it and cut it to length (plus some slack just in case). Strip the wires and attach white to the middle pin, and yellow to the pin on the side where the little red button is.

Solder the wires in place, this is valid also if you use dupont connectors, this will help a lot.

Put the switch back in its holder.

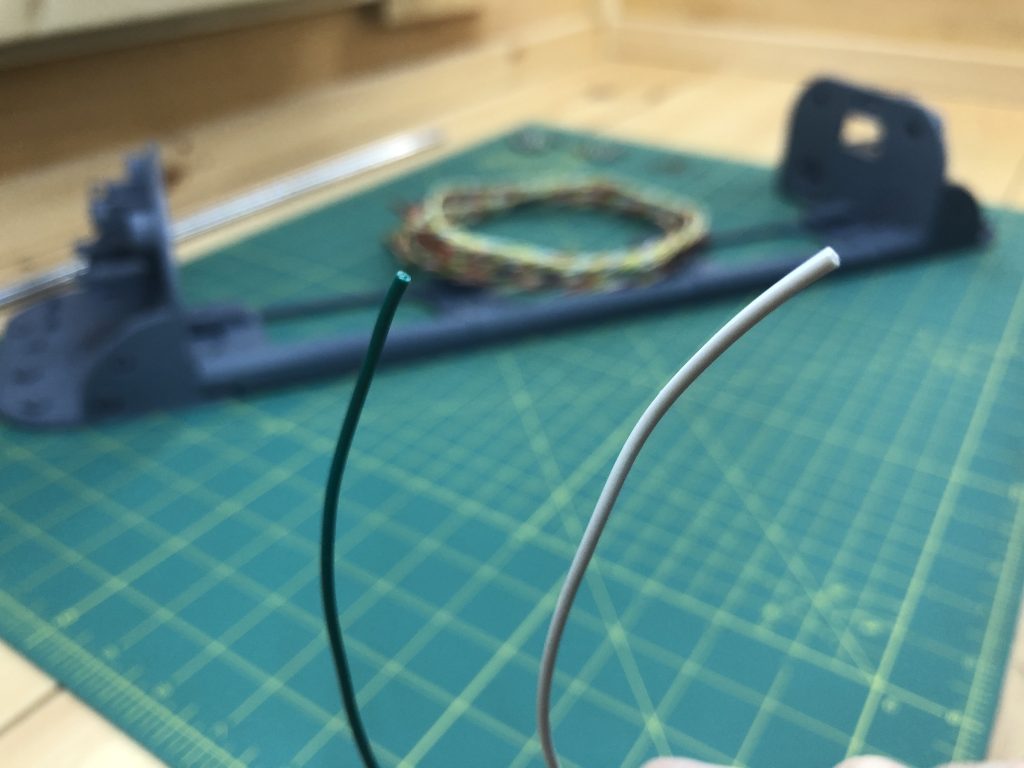

At the other terminal (bottom), grab a limit switch an solder a new twisted pair of yellow/white wires, long enough to reach within the terminal.

Solder both the yellow/white pair from the umbilical, and the new yellow white pair you created into the Pi. In both cases, white will go to a ground on the Pi, you can pick any 2 grounds from the Pi, find them using https://pinout.xyz. For yellow, the switch from the top terminal going through the umbilical should be connected to Pi pin #11 (GPIO 17), while the switch from the bottom terminal should be connected to Pi pin #7 (GPIO 4).

Again components will be floating not in their holders, but you want to be mindful when wiring them up that they’ll be able to get back in there. This is less of an issue with removable dupont connectors where the component can rest in place and wires brought and connected to them directly on the top. With soldering we need to flip the components over so we can solder their bottom side, it’s definitely messier to work with.

You’ll notice you’re left with 1 cable on its own in the umbilical. It serves no purpose :). It’s meant as a backup in case another is faulty, if we mess one up, or for potential future expansions. Now that, is what I call planning ahead. For now we can simply coil it up to prepare it for storage.

With this last wire out of the way, we can slide the gondola to both extremities and make sure it triggers the 2 limit switches (you’ll hear a distinct “click” when it does). You want to gondola to trigger the limit switch before it runs into the terminal, with a bit of room in between to be safe. You can adjust the switch by bending it’s metal arm, do so until you’re satisfied with the location at which it triggers.

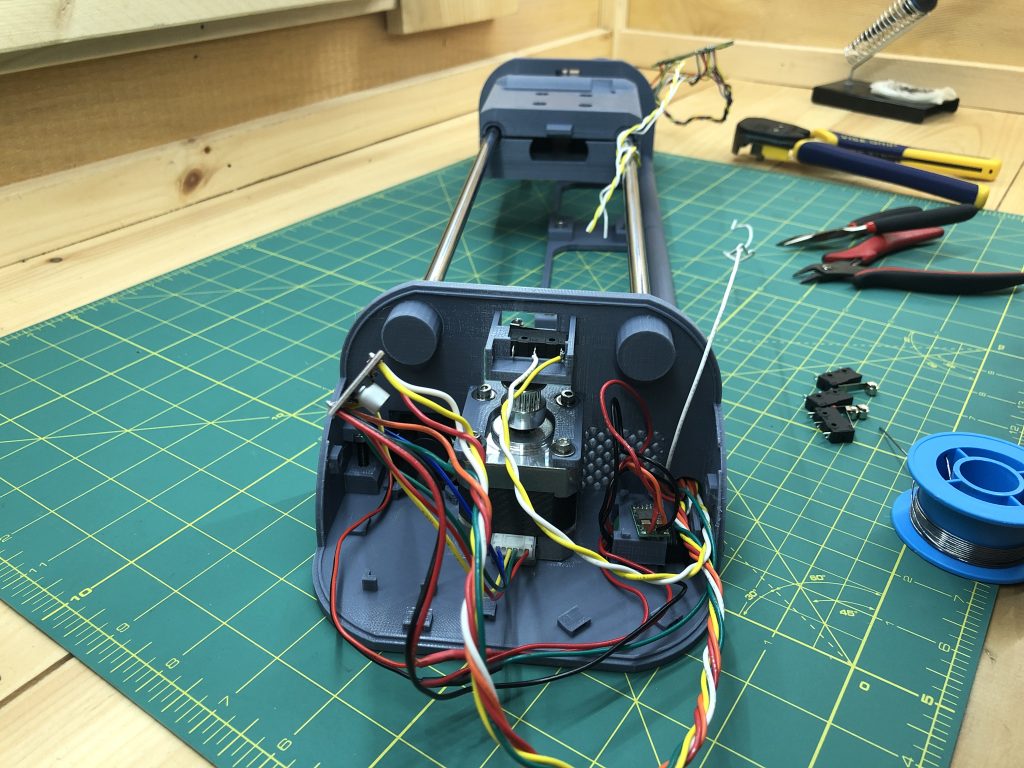

Let’s grab our 2 gondola_top_limit_switch_cap, our 4 gondola_top_screw_cover, and our remaining 2 limit switches. They’ll go on the top of the gondola.

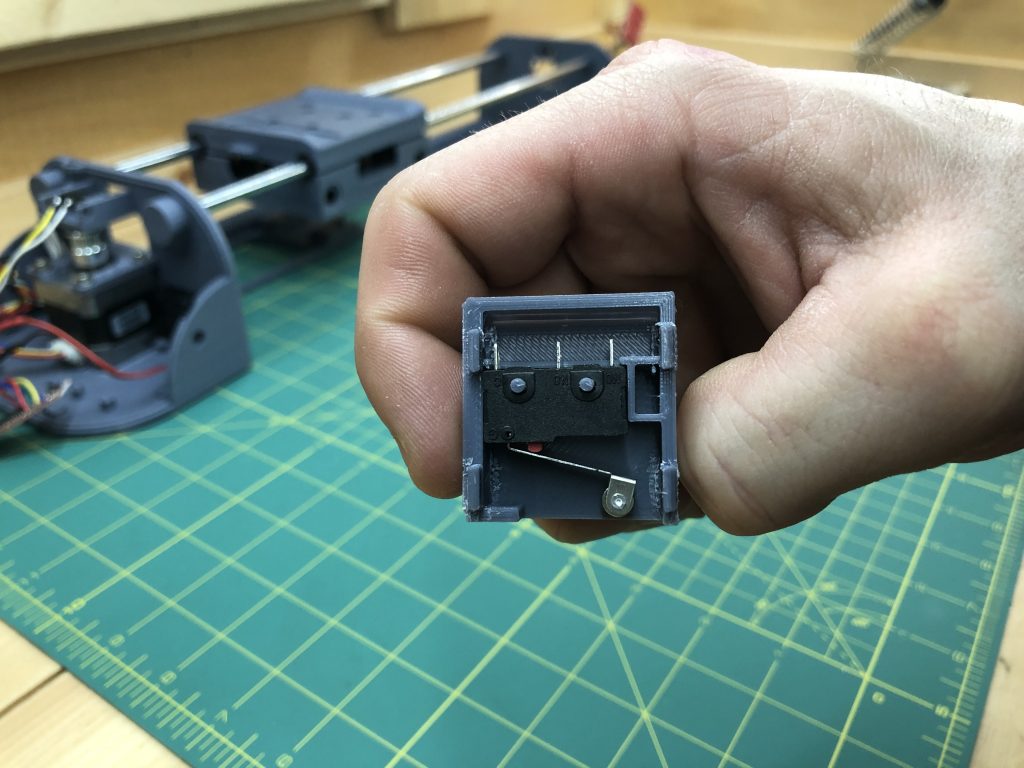

They go in their caps like this:

We simply put the gondola_top_screw_cover on top of the gondola’s innermost hex screws. They’ll be held in place with the limit switch caps. They don’t serve any purpose 🙂 just here for aesthetics.

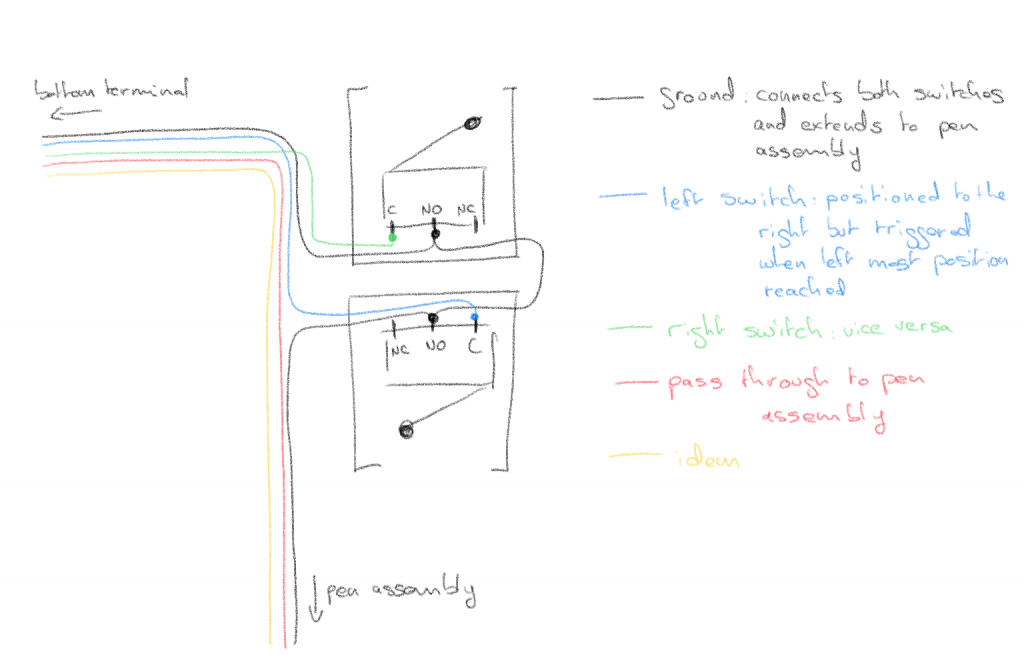

Now we’re going to wire the limit switches on our work surface, and then we’ll put them on the gondola. Wiring them is a bit tricky because you want their wires to go through their cover’s holes. But Also because they share a single ground which will go all the way back to the bottom terminal, and then extend all the way our the X axis, where the pen will go. Other than this ground, they also both have their own signal wire going back to the bottom terminal.

Here’s a schema of what we’re after, it include 2 other wires (yellow and red) which are just passing through the gondola on their way to the pen assembly. We are not worrying about these 2 right now, only black, green and blue.

What my wiring looks like when it’s done:

For the wires which go to the bottom terminal or the pen assembly, make sure they are plenty long enough plus some slack. We’ll cut then to size later.

You can then pressure fit the limit switch covers into the gondola. They’ll click into place but as we mentioned before, 3D printing isn’t always super accurate and so don’t hesitate to shave off plastic where fitting isn’t happening.

As you can see, the ground 2 limit switch signal wires go back to the bottom terminal while another ground is left dangling at the gondola.

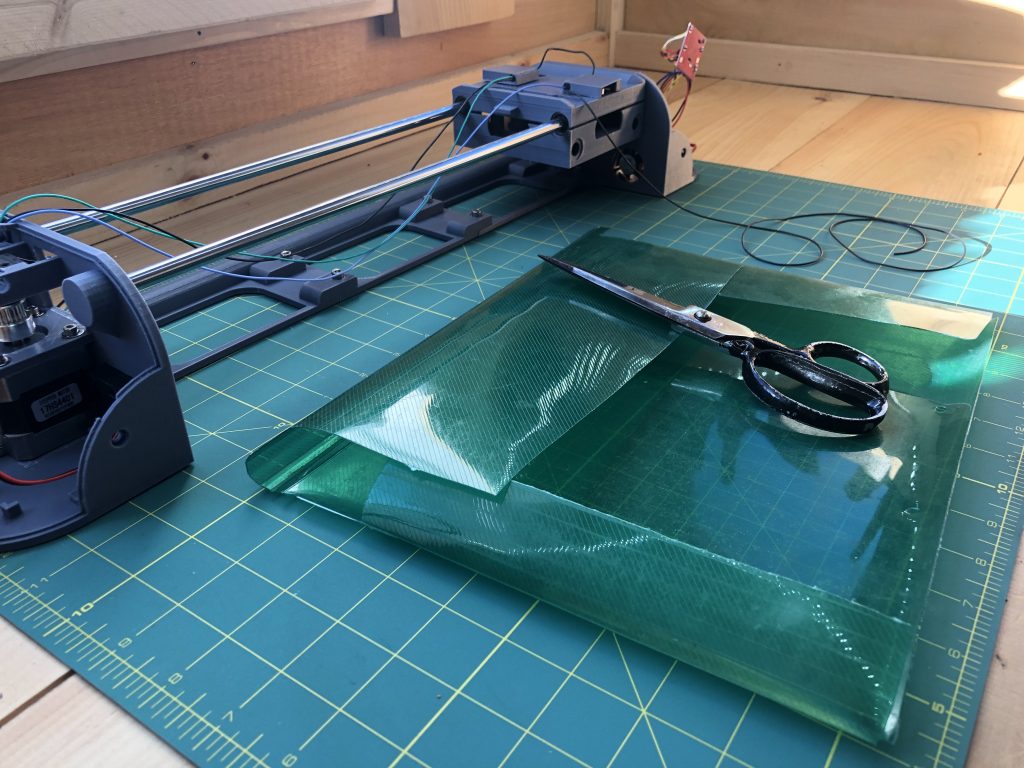

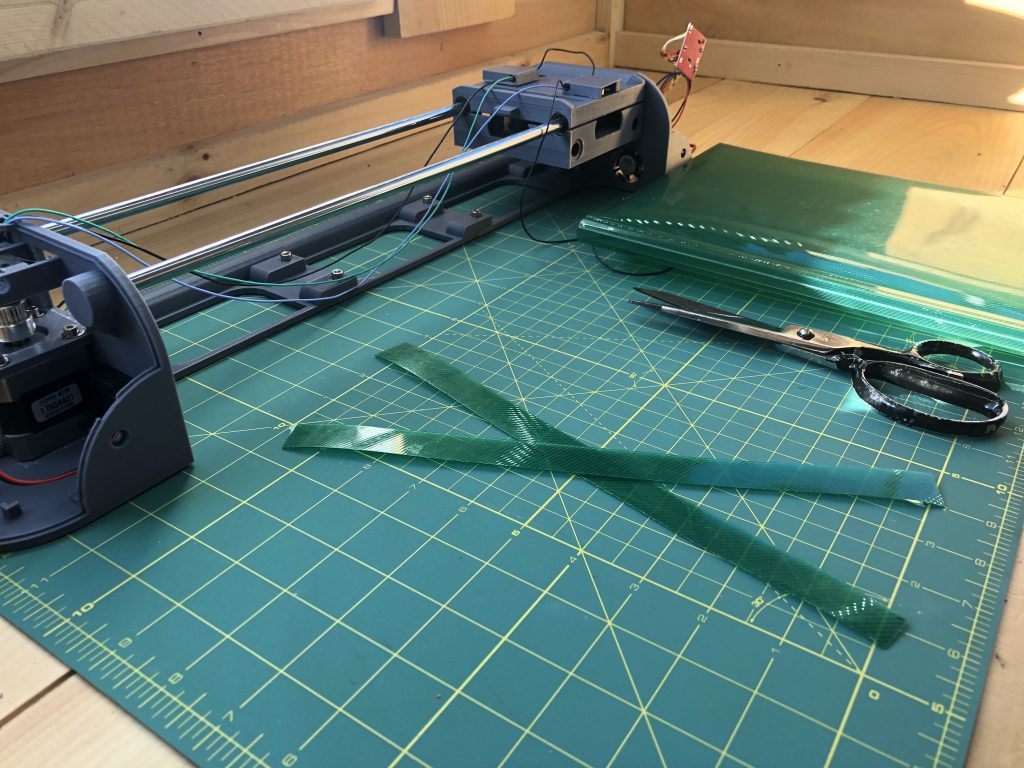

Let’s now grab a piece of flexible plastic. Any plastic will do that can be cut with scissors and give rigidity and flexibility to carry the wires between the bottom terminal and the gondola. I found that a plastic folder that gives me exactly that and I’ve been using it since :). I’m sure there are tons of other options in one’s house.

I’m cutting 2 pieces here because 1 doesn’t suffice to reach all the way across so I’ll join 2. You also will want another length to go on the X axis from the gondola to the pen assembly.

This is the sort of flexibility we want.

With the wires back out of the terminal, we insert an M4 nut in a tricky spot right where the cables enter.

We can then screw our M4x8 hex screw into it, and use the screw as better leverage to pressure fit the nut into its receptacle (inside, away from the terminal wall).

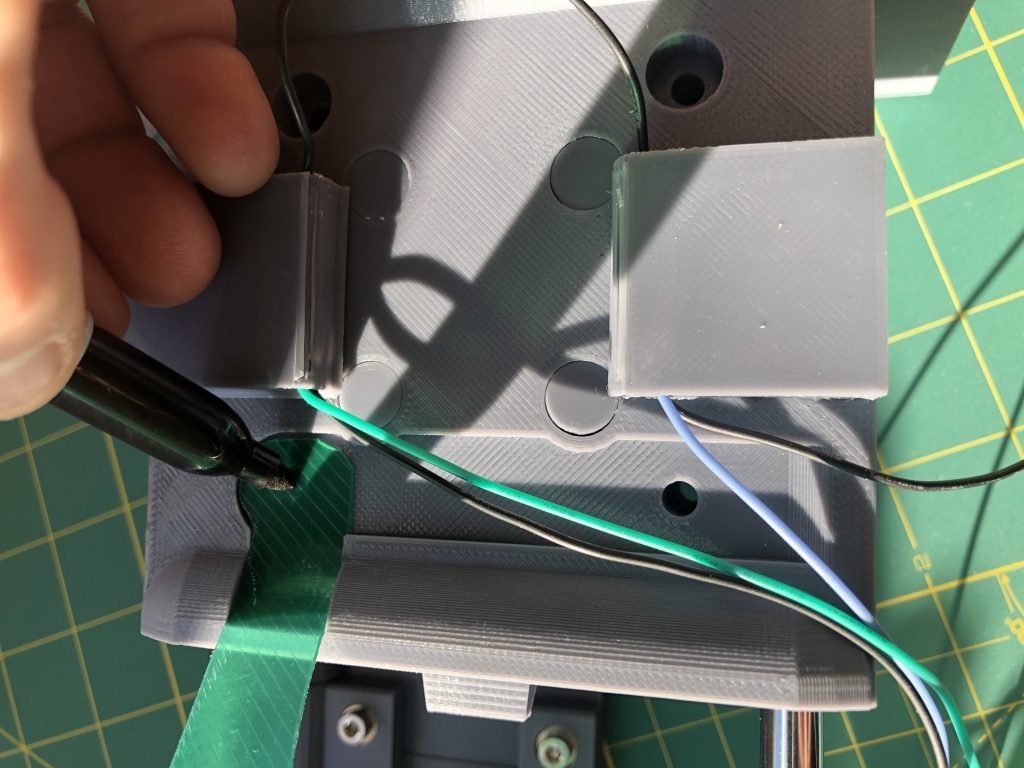

We can now slide our bendable plastic into a slit right next to the arch opening where cables will enter the terminal.

You can then screw in the M4x8 hex screw to lock the flexible plastic in place.

On the gondola side, the flexible plastic goes on top in a slot the same shape as our gondola_top_cable_management. It helps to cut it to a good fit. Then we mark it where a screw will lock it into place going all the way through the gondola.

We then drill that hole in the bendable plastic.

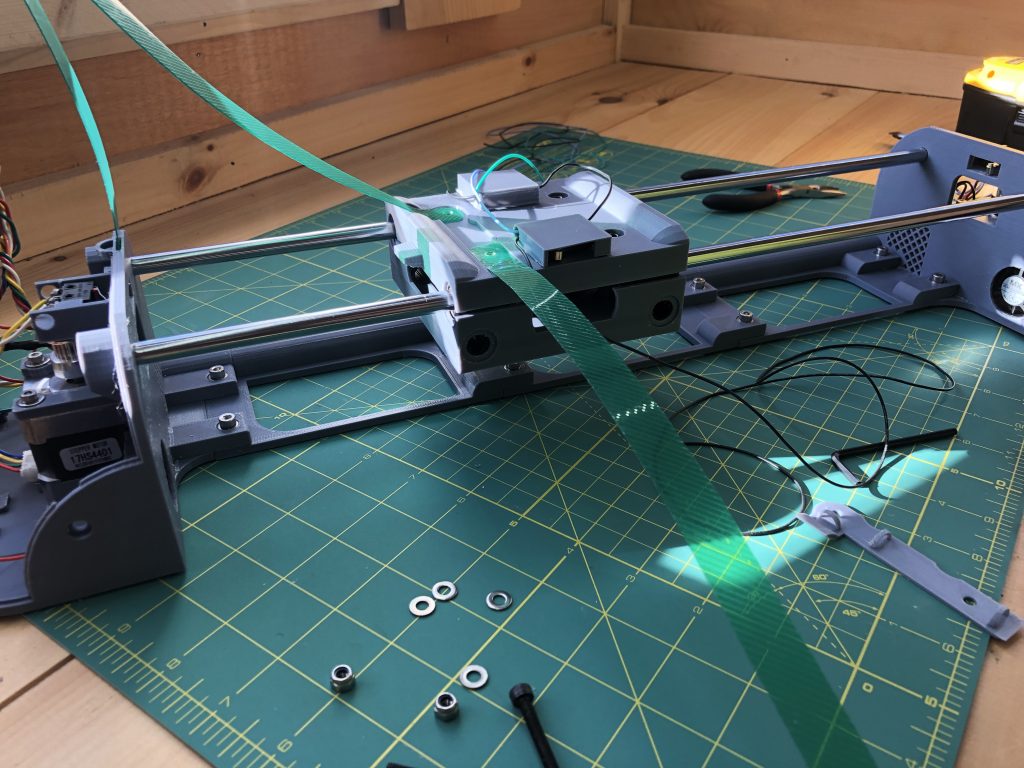

We put it back in place. We mark and drill another hole on our X axis length meant to extend out the the plastic assembly. This is what it looks like with all our flexible plastic lengths in place.

We can now grab our gondola_top_cable_management and place it directly above our flexible plastic, along with 2 M4x40 hex screw ready to go through the gondola. 2 M4x34 hex screws go into the last 2 outer holes of the gondola. We also use washers for the screws, and at the bottom for the lock nuts.

As previously when we screwed in the belt roller axles, it’s a tricky exercise to tighten these 4 new screws on both sides of the gondola. These screws are holding the gondola together and are meant to be tighter than the axles ones we did earlier. Still though, definitely don’t overtighten and keep an eye on how well your belt rollers are moving.

When this is all done:

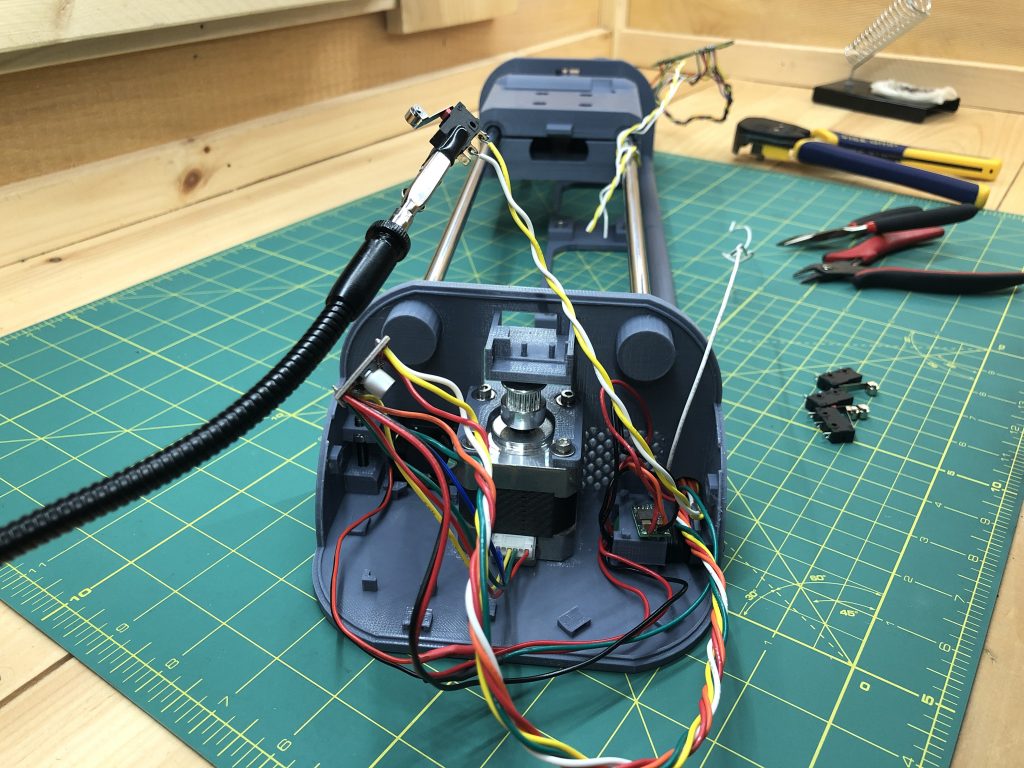

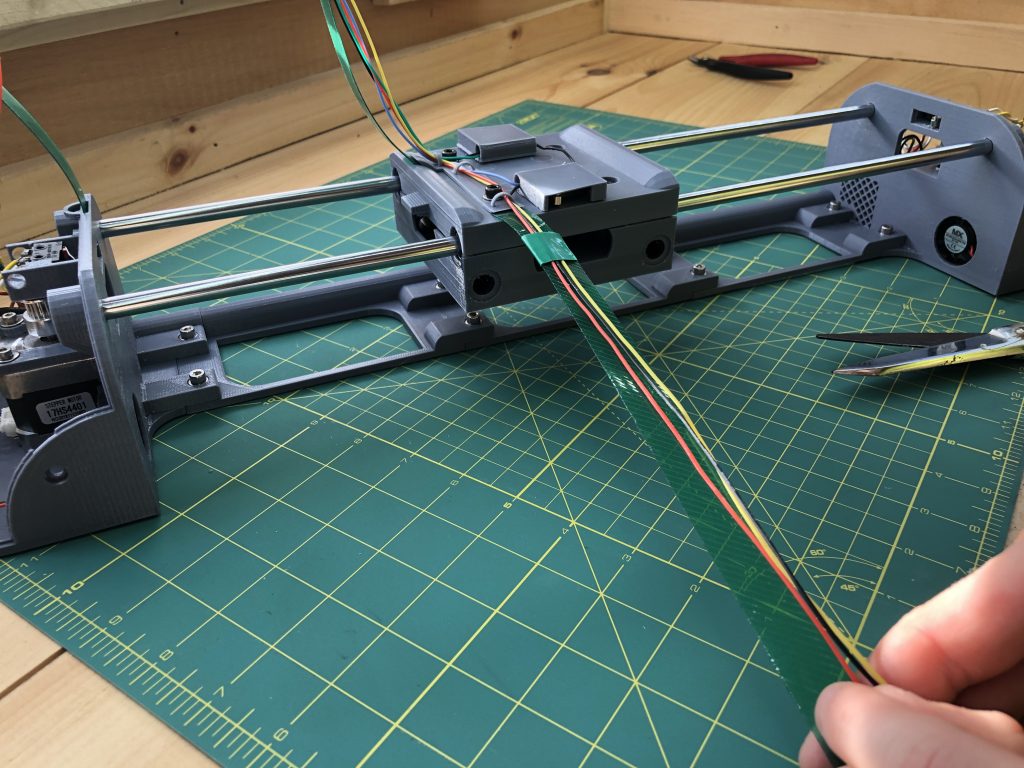

We then add a red and green cable going all the way from the bottom terminal, through the gondola, and to our yet to be built pen assembly. We can use the little hoops on the gondola_top_cable_management to keep our wires tidy. I uses electrician’s tape on the flexible plastic to hold the wires.

We finally get to connect our 2 gondola limit switches 🙂 that was a serious tangent… Grab them both, and the ground.

Connect the ground on any ground on the Pi. Then connect the limit switch situated to the left looking at the picture above to Pi pin #3 (GPIO 2). This is in fact the limit switch triggered when the pen assembly reaches it’s right most position and we’ll refer to it as the “right limit switch”. But looking at it this way, it’s on the left :). The other limit switch, the “left limit switch” situated to the right on this picture, goes to Pi pin #5 (GPIO 3).

We can now power the plotter once more and head to its web interface. The Mechanics sections will show the state of the limit switches. You can trigger the switches yourself manually and verify that their state is toggled as you do so (the state isn’t reflected on the web interface immediately, it might take a second or 2 to show).

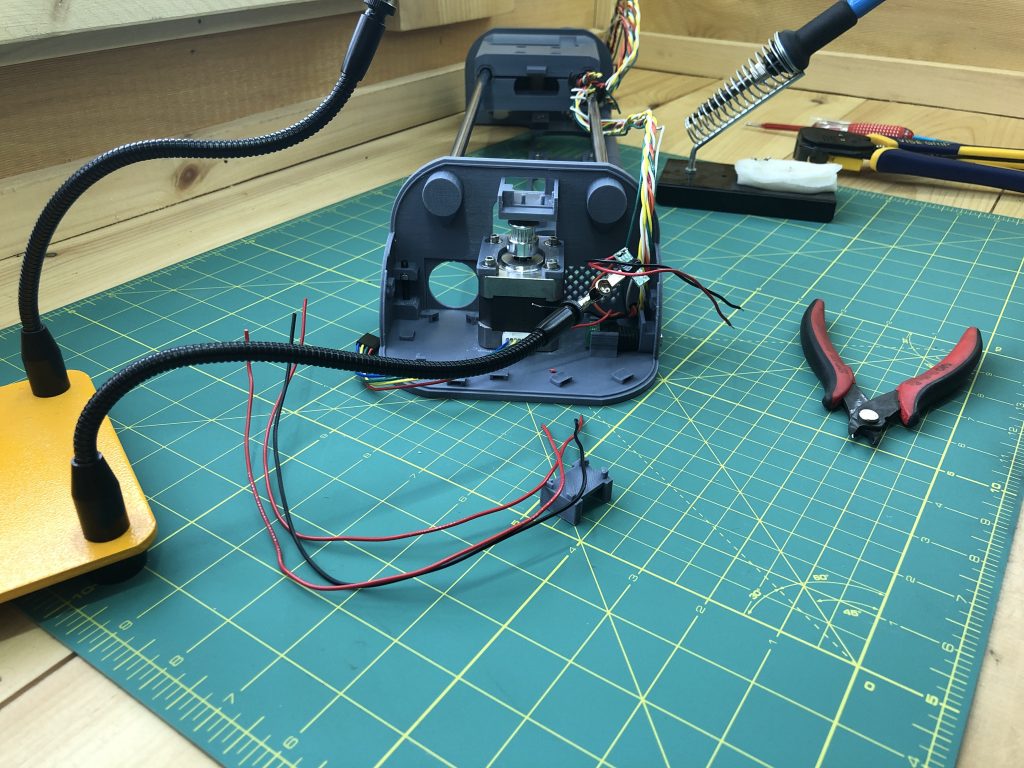

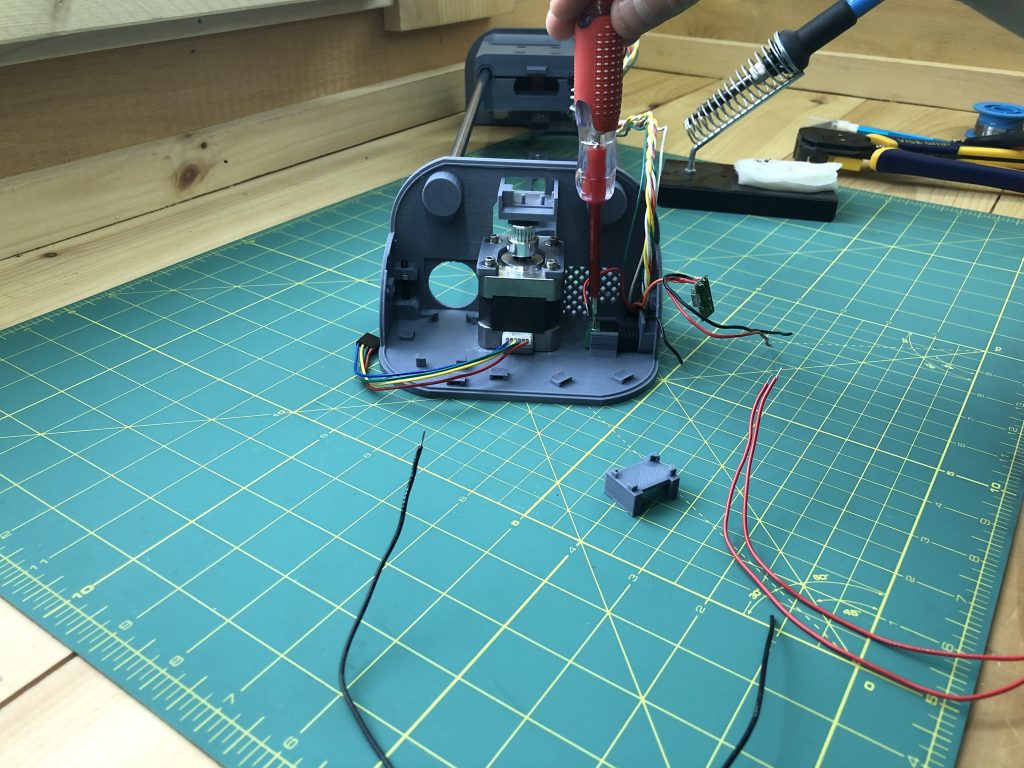

9. Servo Motor

Electrical:

servo motor

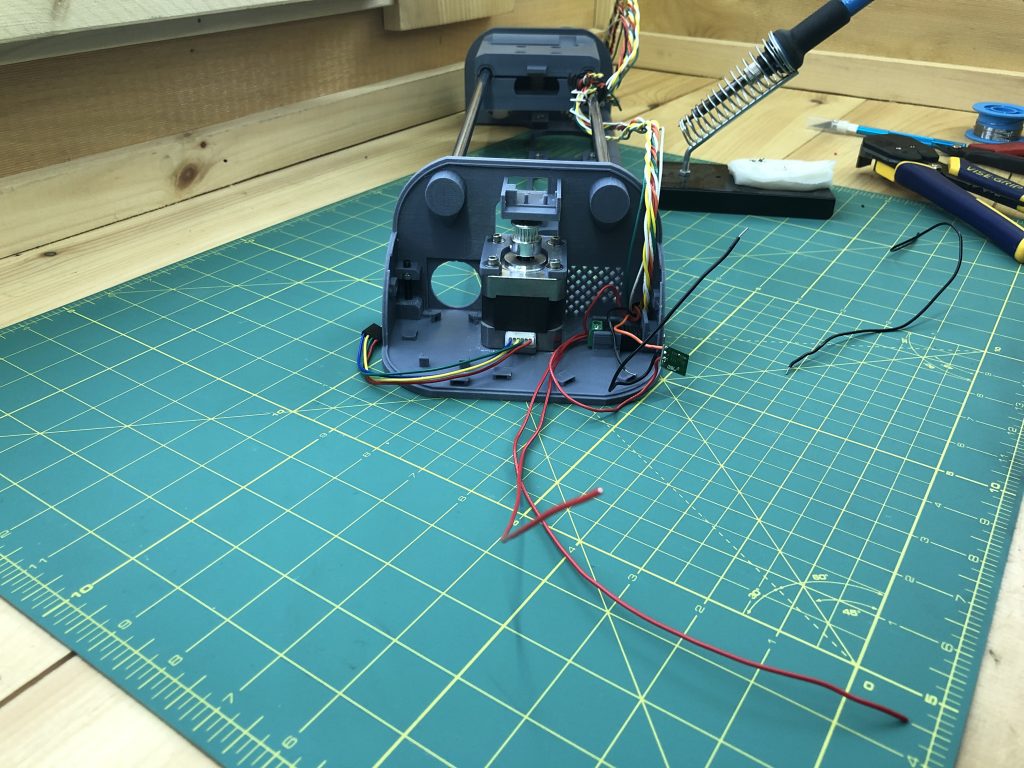

We’re about to do our last wiring :). Grab the red and yellow wires you have brought into the bottom terminal from the gondola (the ones that go all the way out to the pen assembly). Connect the red one to Pi pin #4 (5V power), and the yellow one to Pi pin #16 (GPIO 23).

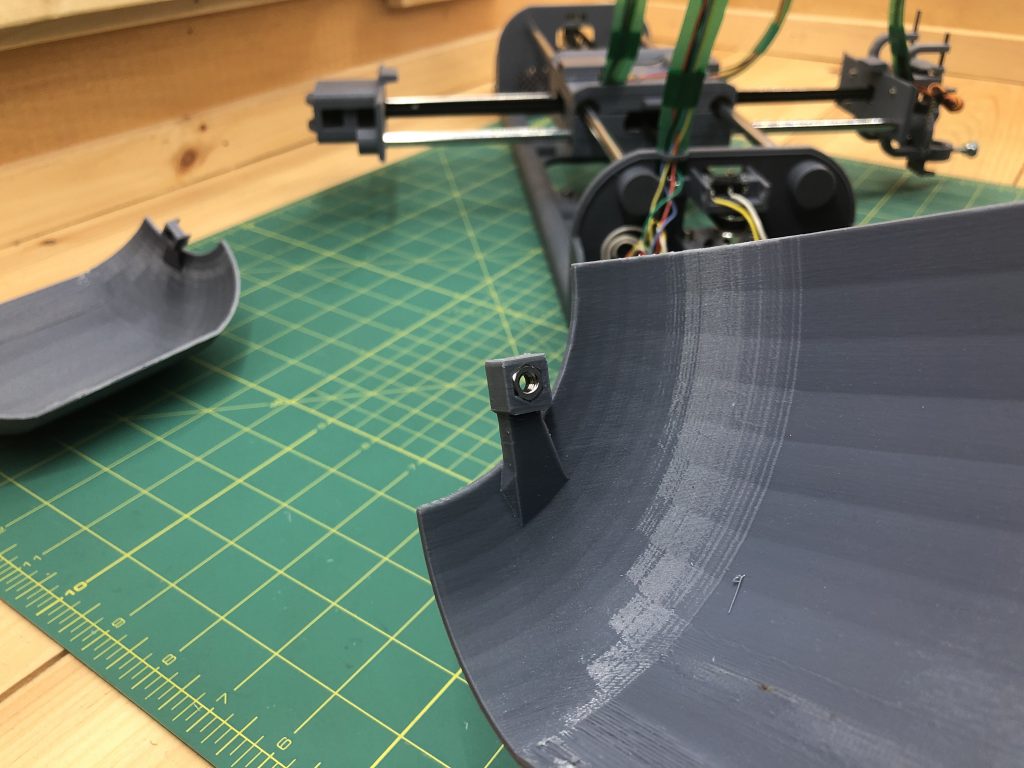

Where the pen assembly will go, we cut and strip the wires, you’ll need to use your X axis linear rods to estimate where to cut. We will actually be terminating these wires with a dupont connector matching the servo motor’s. This is because these servos will wear and die. They are a part with limited cycles and so we want it to be easily replaceable.

When it’s connected, we can power our plotter once more and head back to the web interface. The Mechanics sections has “Pen Up” and “Pen Down” buttons to test the servo with.

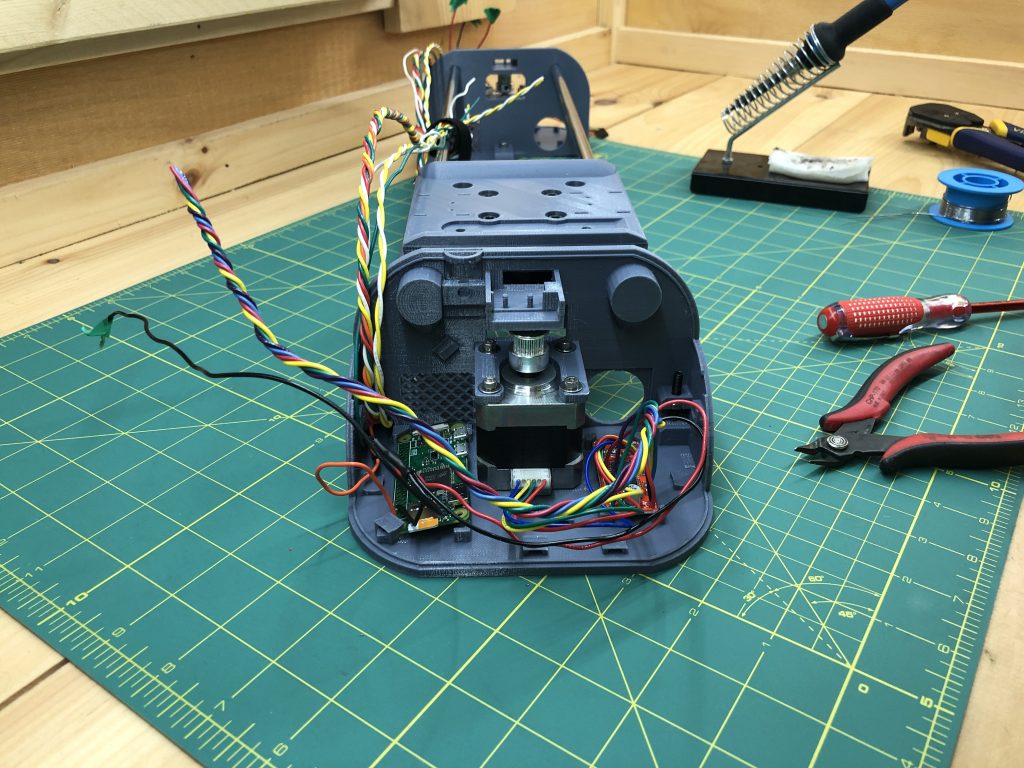

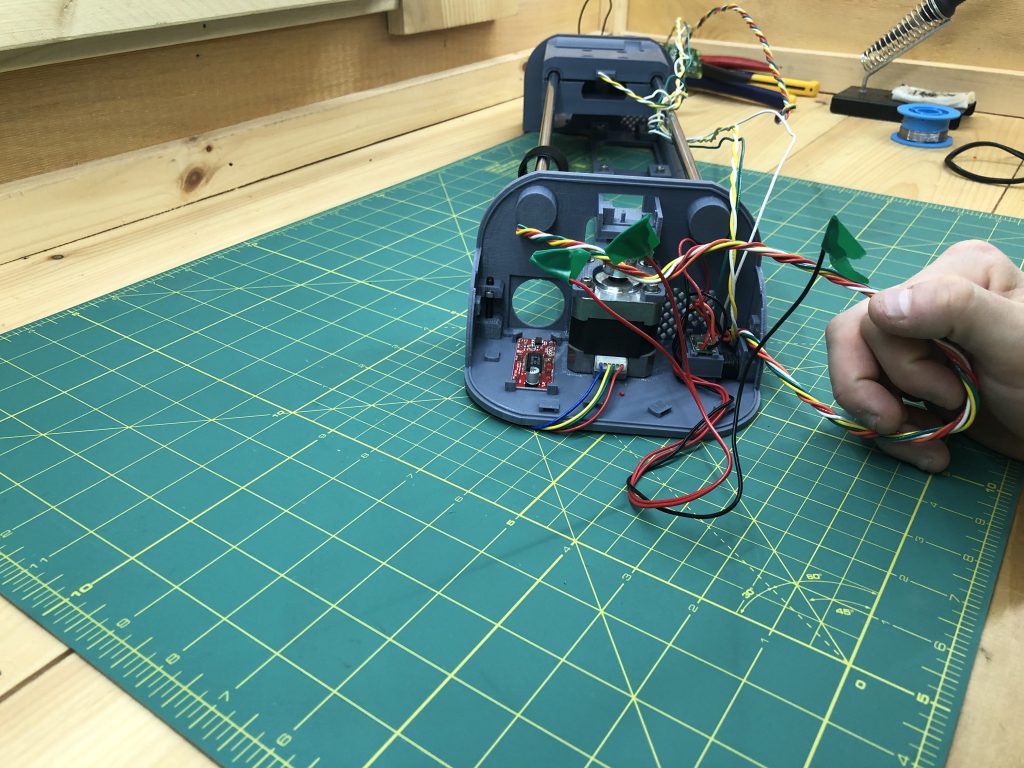

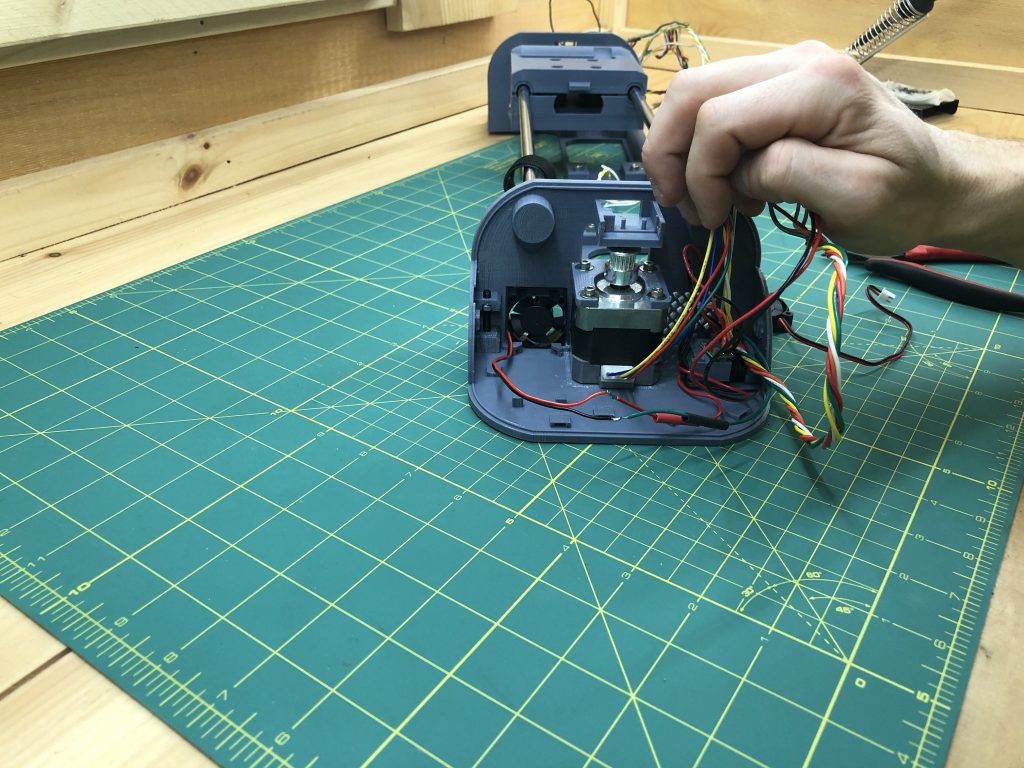

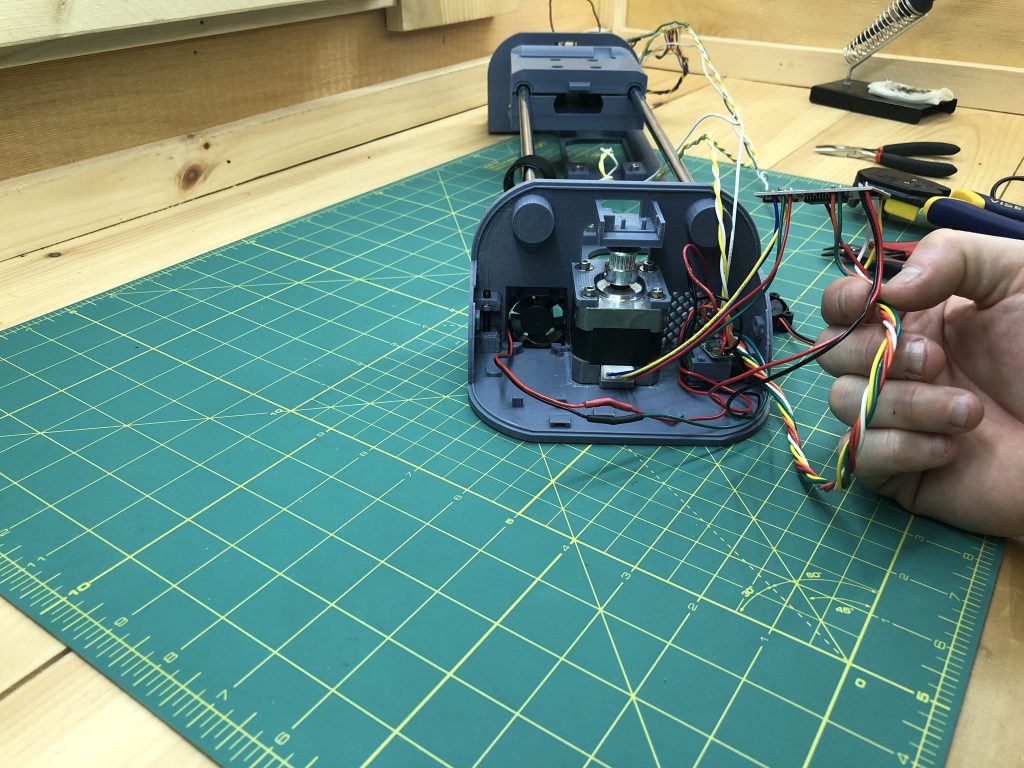

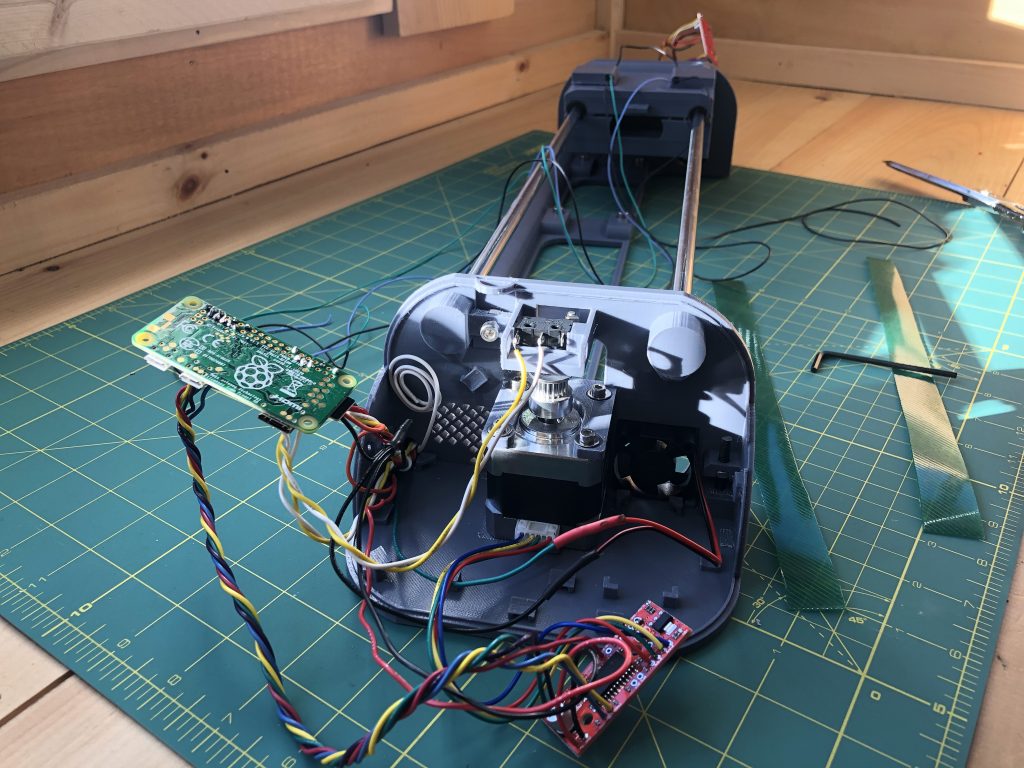

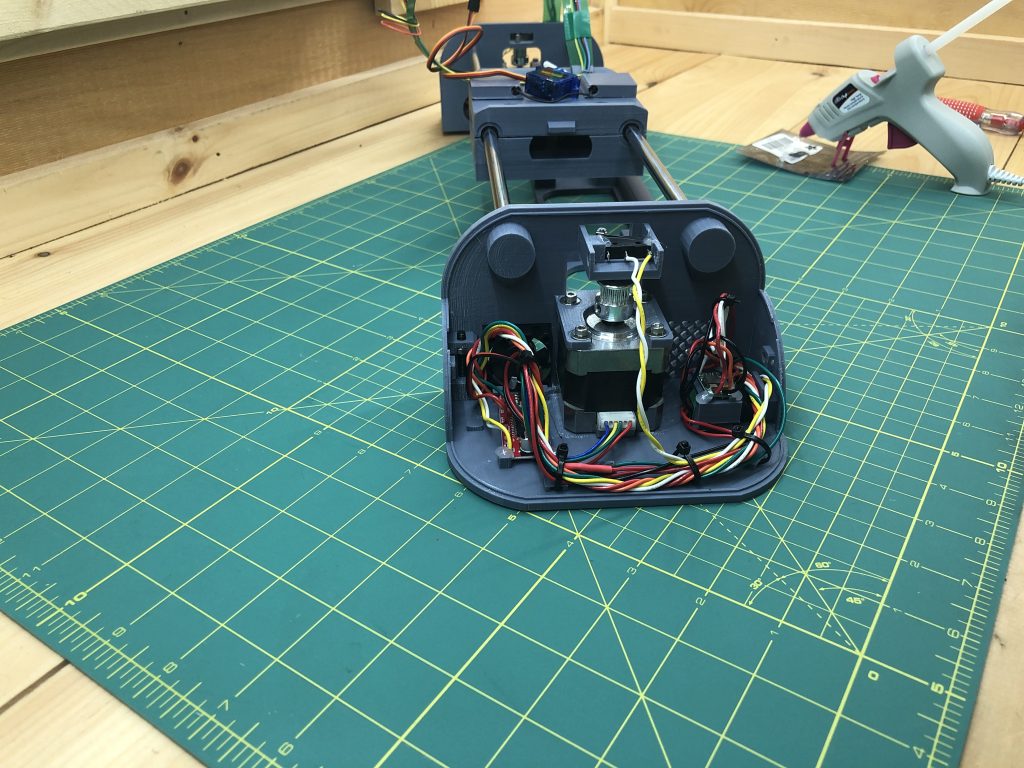

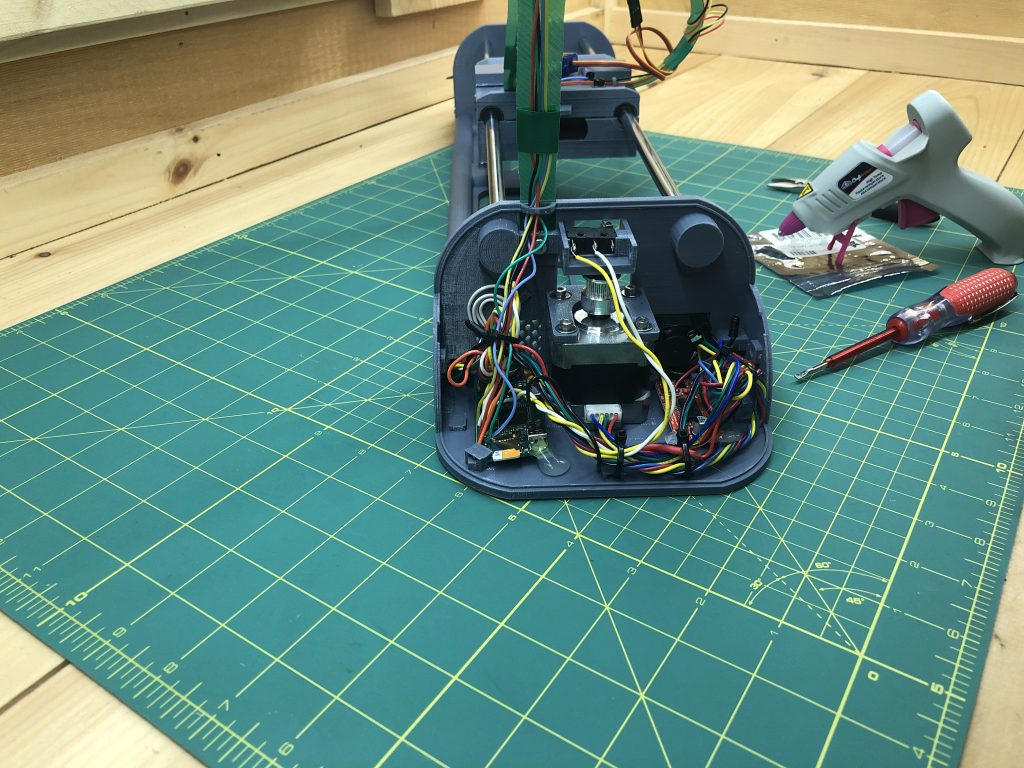

We are done with wiring! We now get to tidy up our terminals by placing components in their holders and managing wires. There is no right solution for the wires, the model simply has opportunities for small zip ties. I used a glue gun to hold the components in place on the corners which aren’t covered, I usually prefer sugru mouldable glue but I didn’t have any.

My Pi is a a bit of an ill fit here but that’s ok.

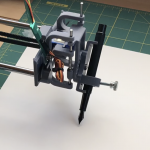

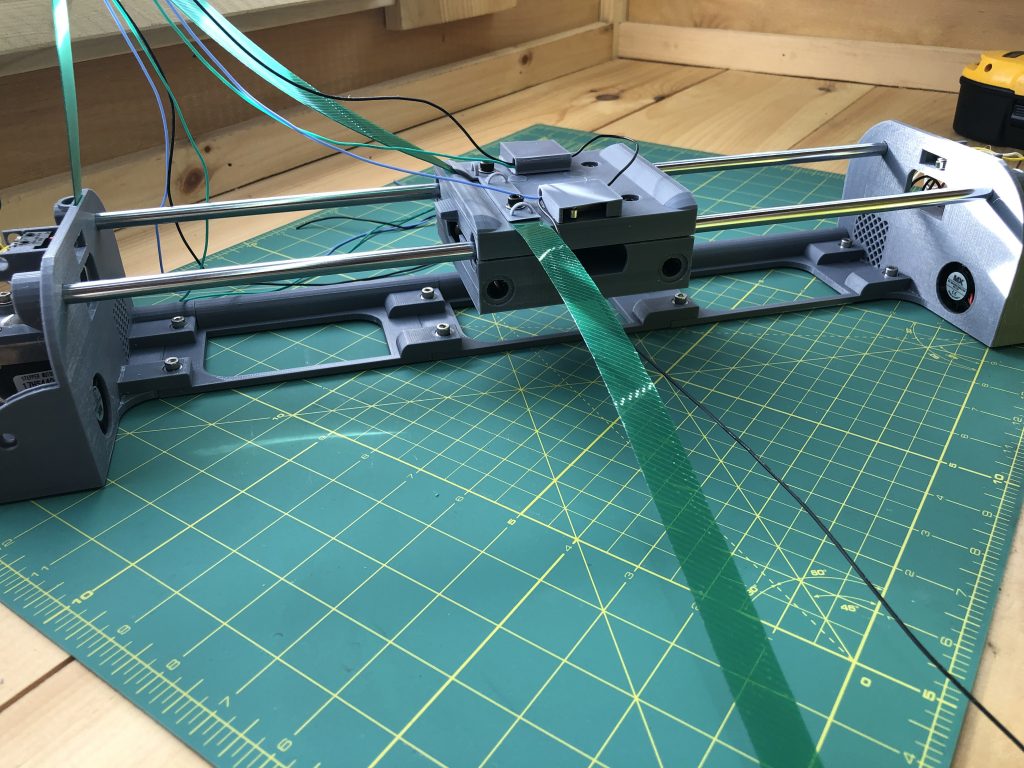

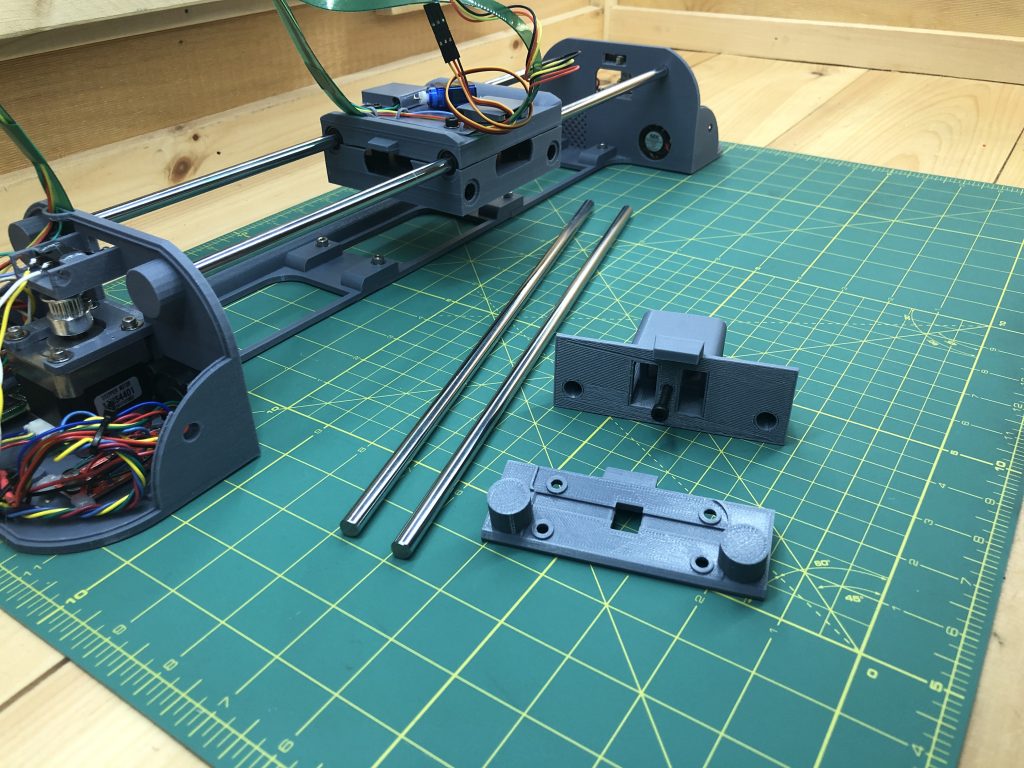

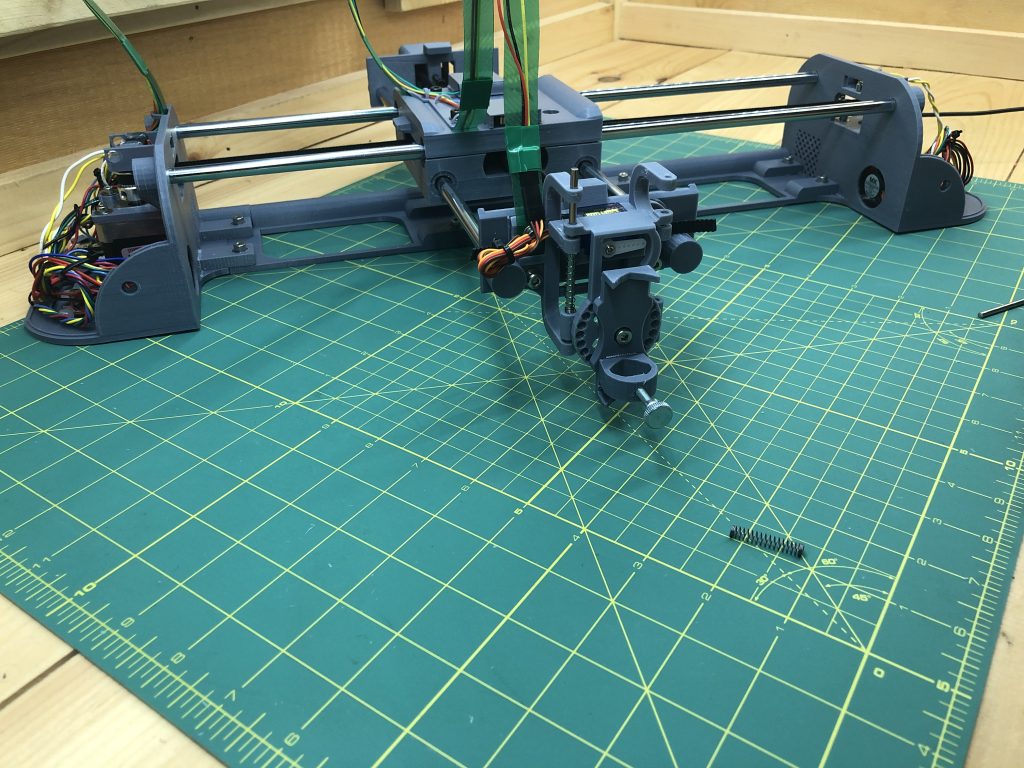

10. Pen Assembly

Hardware:

2 8x350mm linear rods

2 3x100mm linear rods

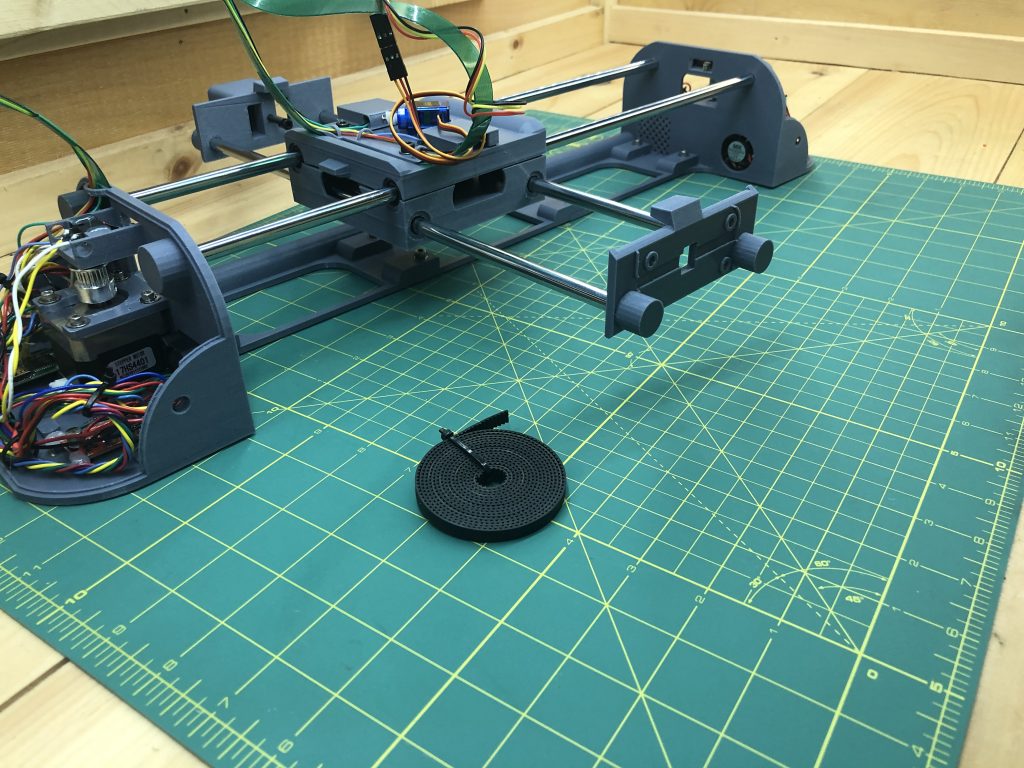

1 GT2 belt

1 M4x8 hex screw

1 M4 pen holder hand tightening screw (or a regular less fancy M4 screw)

2 M4 nut

4 M4x12 hex screws

4 washers

3D printed:

front_assembly_x1

front_assembly_servo_holder_x1

front_assembly_pen_slider_x1

front_assembly_pen_holder_x1

Previously build:

the back assembly belt roller from step #3.

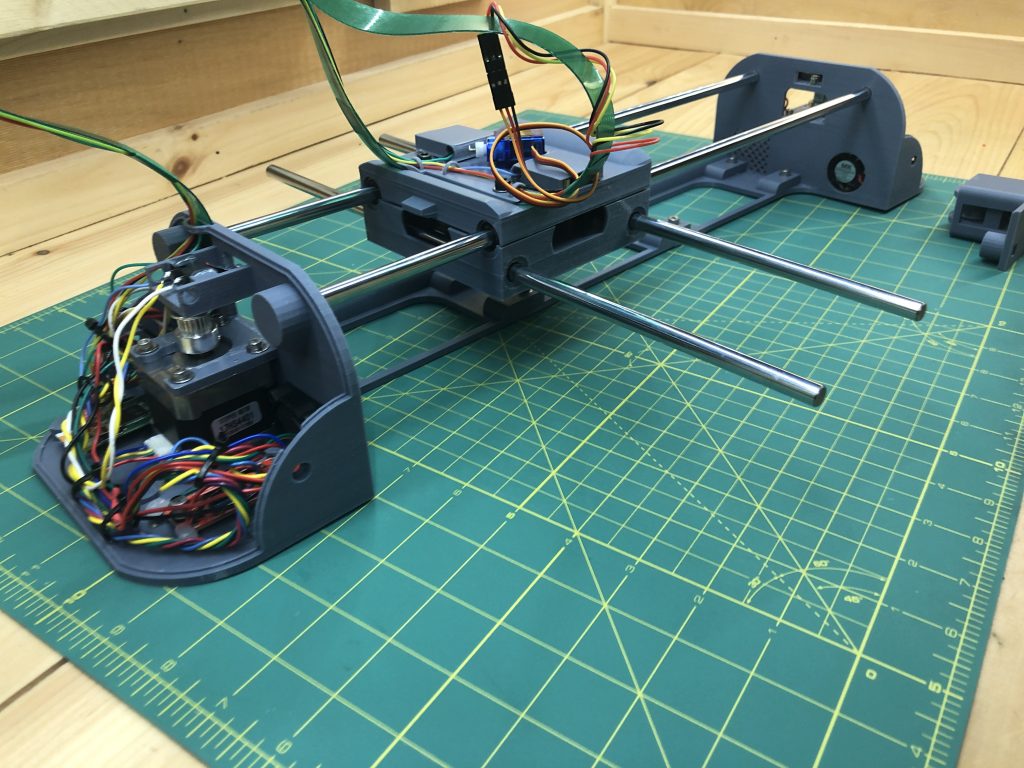

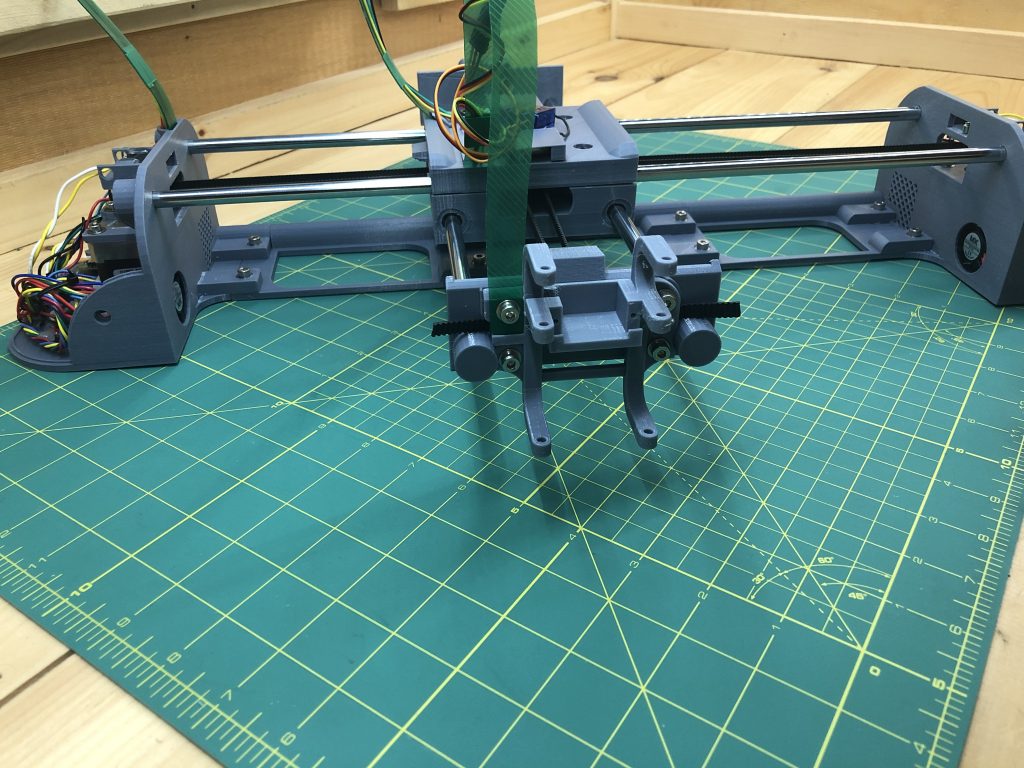

Run the rods through the gondola.

Add the back assembly belt roller.

And then the front_assembly.

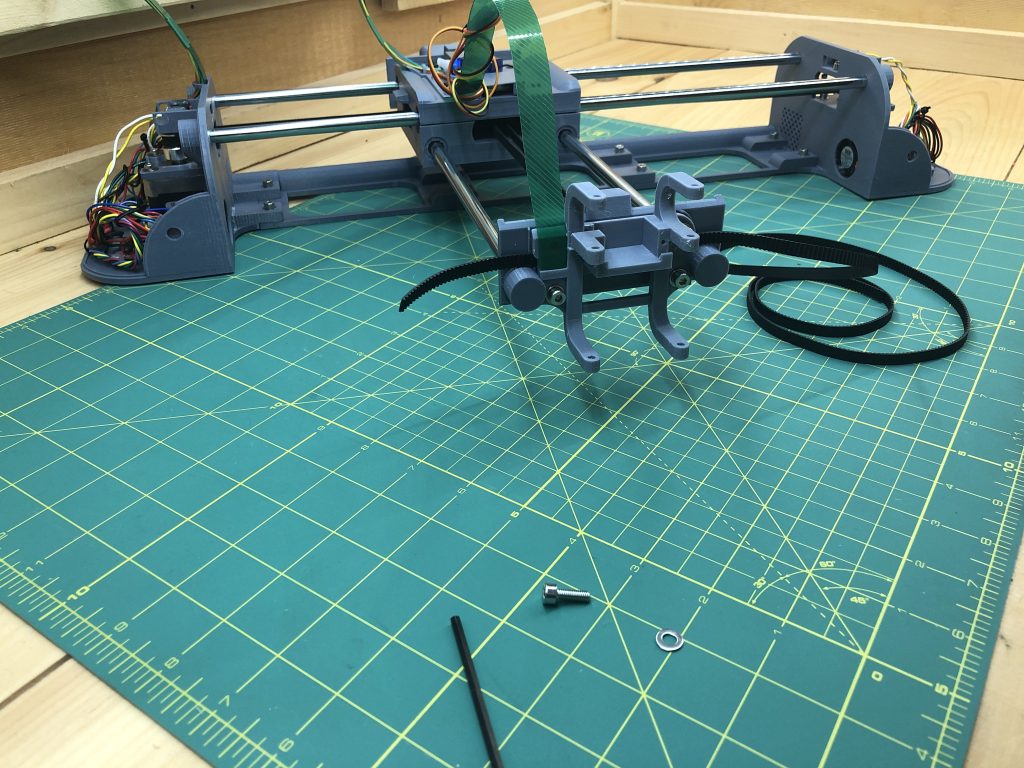

Get your GT2 belt.

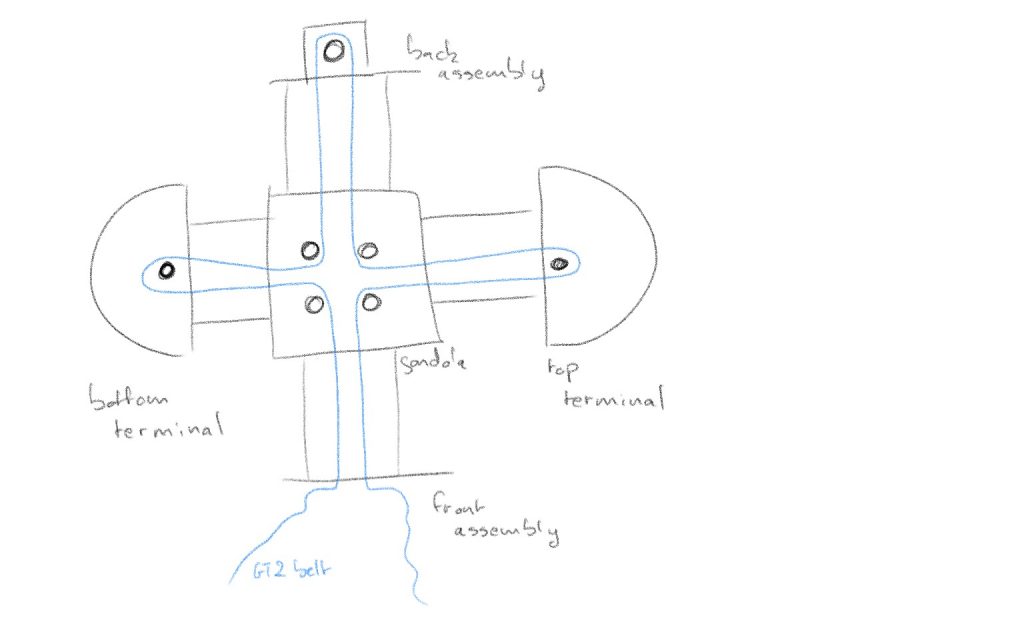

Run it through the plotter and out the front assembly. It’s hard to describe in words exactly how so here’s a schema:

This is an annoying thing to do with several attempts to be expected. But it’s not hard. I find attaching a bent but rigid guide to my belt helpful. You wand to make sure that the belt doesn’t twist and is always flat with its teeth eventually facing the stepper motor pulley.

Pressure fit 4 M4 nut into receptacles in the back of the front_assembly.

Grab your front_assembly_servo_holder. It has teeth in the back to hold the GT2 belt in place when pressed against it.

Put it against the front_assembly and screw in the bottom 2 holes with M4x12 screws and washers. You want to hold the belt tight until these 2 bottom screws are in place and holding it for you.

Slide in the flexible plastic carrying our servo wires from the gondola, drill a hole in your flexible plastic matching that of the front_assembly_servo_holder, as you’ve done before. Screw in the top 2 holes with 2 more M4x12 hex screws and washers.

Put your servo motor in (without the arm).

Plug in the servo, plug in your plotter, go to the web interface, and click the “Pen Down” button. Now put in the servo’s arm horizontally and screw it in.

Tidy up the servo wires.

Pressure fit an M4 nut in the receptacle in the back of front_assembly_pen_slider.

Place front_assembly_pen_holder on top of front_assembly_pen_slider, it has a circle of little dots matching little holes meant to adjust rotation of the writing instrument. We’ll just do a straight angle for now.

Screw it in place with an M4x8 hex screw.

Inside where the pen will be held is a receptacle for another M4 nut, pressure fit one and screw it a hand tightening M4 screw (or a regular M4 screw if you want).

Looking good.

Grab 2 M3x100mm linear rods (you can salvage some from old CD drives).

The rods need to slide without friction as much as possible. Until they do, you can hand drill the holes of your newly built pen holder. Be extremely careful now to remove too much material or your pen holder will have play.

Grab 2 sacrificial click pens. We’ll cannibalize them for their springs.

Then attach the pen holder to the plotter one rod at a time, placing the springs strategically. You might need to adjust the springs by forcing them to a new length.

Of course now is the time to try our “Pen Up” and “Pen Down” buttons in the Mechanics section of the web interface.

Success!

11. Final steps

Hardware:

4 M4x8 hex screws

4 M4 nuts

14 rubber feet

3D Printed:

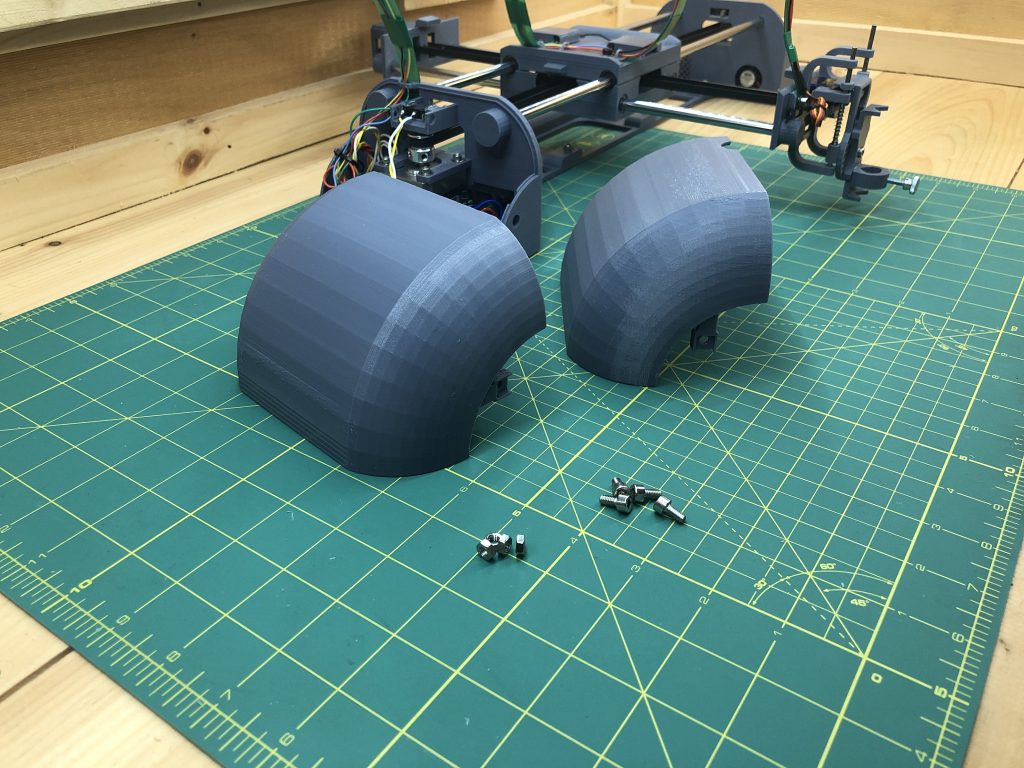

terminal_top_cover_x1

terminal_bottom_cover_x1

Electrical:

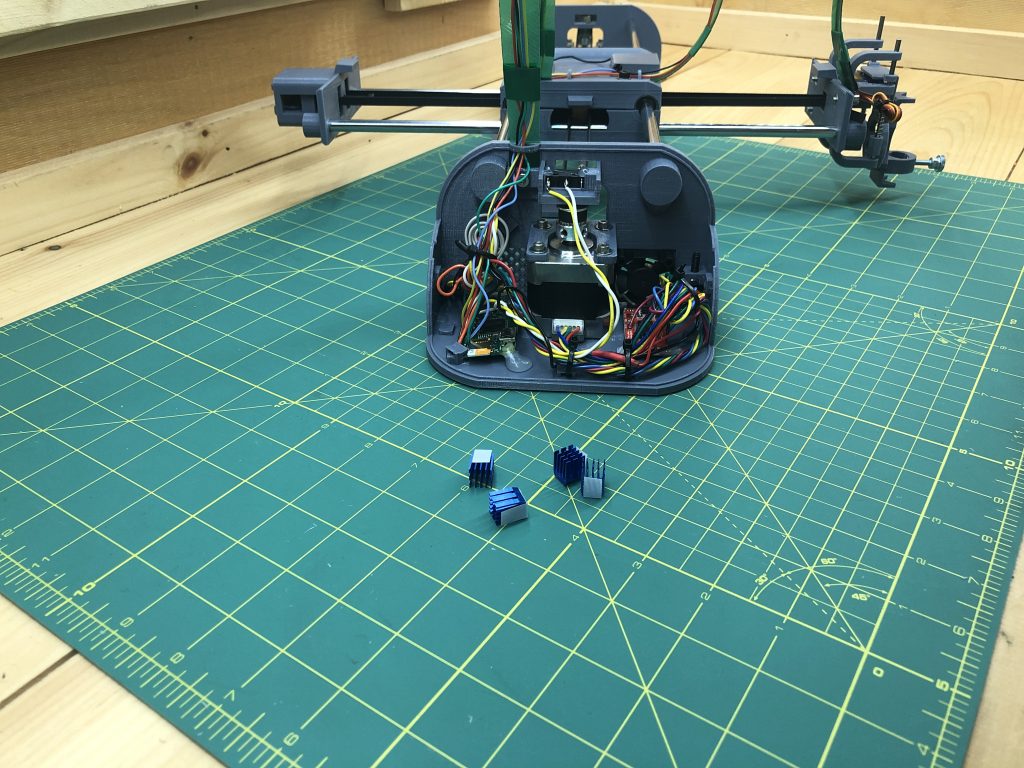

4 heatsinks

Our stepper drivers can produce a lot of heat, on top of being next to a fan, we’ll give them heat sinks. They just stick to the chip and it takes 2 to cover 1 chip. Do this for both terminal’s stepper drivers.

Grab your terminal covers.

Pressure fit 4 M4 nuts in each of their little protruding arms.

Wiggle them in place on top of their respective terminals and screw in the M4x8 hex screws to the side. Getting them in place is a bit of an art, you want to make sure that the little arms embrace their matching shape in the terminal.

Finally, flip your plotter over and stick 14 rubber feet where there are receptacles for them.

Voila!

Head over to the web interface and try a simple plot to make sure everything is functioning correctly.

As an afterword to this extremely long instruction set, I would like to congratulate you for your patience and tenacity. I refined this plotter over years and many, many prototypes. I tried very hard to provide instructions which were as clear as possible while making no assumption of understanding of any kind. It contains all the tidbits of missing information I had to find the hard way when I was researching how to build such a thing. I hope to have made this project free of the blind spots and dark corners I found myself into. Equally I hope for the software stack to significantly lowers the bar of entry to just get a plot going. If you find anything missing or unclear, please do reach out with a comment or email and I’ll fix it. May your new toy scratch your plotting itch :).

Please do get in touch if you build this, whether or not you are having issues. Thank you and take care!

Use Instructions

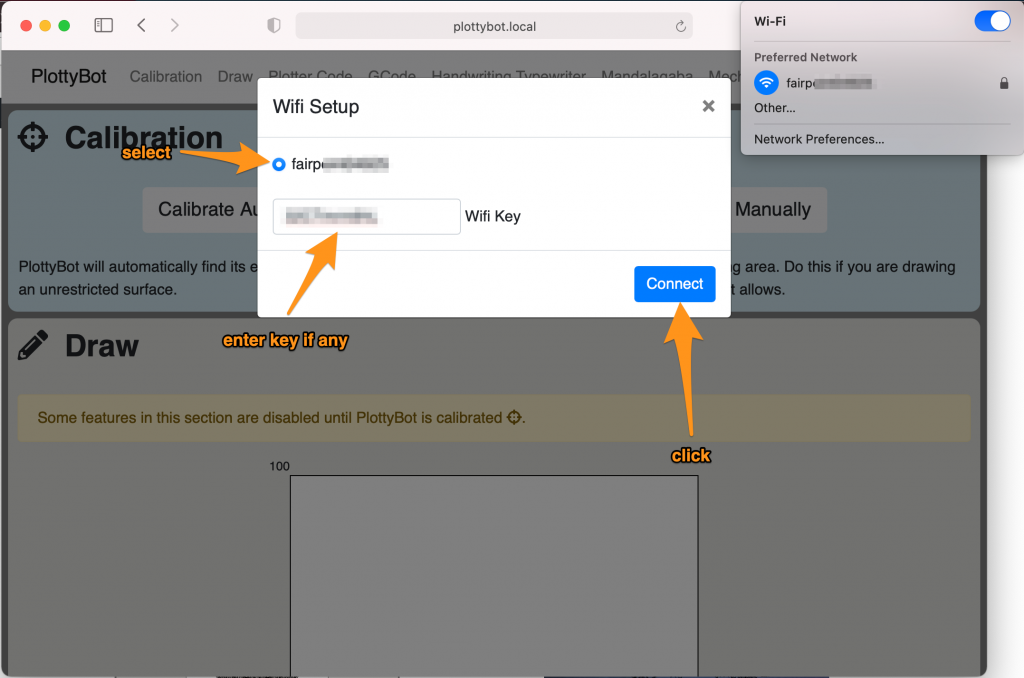

Connecting to Managed wifi

To avoid having to point your computer to PlottyBot’s wifi for use, which disconnects you from the internet, you can instead point PlottyBot to your home wifi and have it connect to your usual network when it boots. If you boot it outside of your home wifi’s range, it will still span its ah-hoc network so you can always connect to it.

After your plotter is connected to your network, it can still be accessed via http://plottybot.local or http://10.0.0.5.

This feature isn’t well tested. It works at least on WEP & WPA2 networks.

That’s it?

A lot more could be said on how to use the plotter. I hope that a lot of it is intuitive enough. If not Dave Evans has contributed a very nice Getting Started document. Thank you Dave!

FAQ

- What’s up with the sound the plotter makes? The stepper motors have inconsistent pitches when moving straight.

This is the result of 2 phenomenons, the first is that there is an acceleration algorithm in effect. The second and most likely culprit is that the sleep time is enacted by Python in software land. Python on a Raspberry Pi does not have access to dedicated hardware to “sleep” (wait) between stepper motor steps in a way that is accurate at the millisecond resolution. Python is competing for CPU cycles with other processes on the Pi. What this means is that the “attention” Python gets from the Pi is not dedicated and so the sleep time between steps may vary a little in a way that you’ll hear. Equally true is that sleep times are a minimum, if you instruct Python to sleep for 0.01 millisecond, it will sleep at least 0.01 milliseconds, and so while you can count on Python on a Pi to not sleep so little as to break the mechanical limits of how fast a stepper motor can move, you can’t count on it not sleeping a little more which is something you’ll hear. This is a draw back of working with stepper motors on a Pi, but the other processes getting attention make the Pi a very desirable device to step motors on regardless. An Arduino could not step motors while being connected to WiFi and serving web pages. At the end of the day, all your stepper motors do is sound a little funny in exchanged for a fully fledged software stack.

- Why is the plotter so slow?

The software comes with default settings for the motors which are optimized for reliability, not speed. This is especially true as each build introduces variation (belt tension, bearing smoothness, et cetera). Once your plotter is working and you want to make it snappier, head over the the “mechanics” section. Here you can tweak these settings, I recommend looking at the settings for the pen up & down action first, limiting travel and delays on this action will have a drastic impact on the overall longevity of a plot.

- What are the maximum plotting dimensions?

The base build documented here can plot up to 324mm X 225mm. Please note that these are the limits of the ideal 3D model and you are likely to shave a few millimeters off the ends where the limit switch should trigger before the gondola actually makes contact with the terminals.

- Can we change the plotting dimensions?

Yes, within reason.

The X axis can be changed simply by using longer rods all parts are the same you’ll just need more belt length. But this axis is not supported on both ends and so the further your reach out the more likely you will run into balance issues. I built a bigger model with 450mm rods on the X axis and it performs fine.

As for the Y axis, it is supported on both ends and can likely be made much longer, but when you do so you need to make the slab part longer. Here is a link to an elongated slab to support 600mm rods on the Y axis. If you need a different length and can’t work with the STL let me know in the comments.

Future Features & improvements

- cover model isn’t perfectly flat at the bottom (printing problem)

- make gondola bottom holes bigger to grab on the lock nuts

- does Python sleep better with nice?

- DHCP server doesn’t turn off when joining managed network (at leat on Pi Zero 2) see comments

- interference from DC cooling fans?

- need a way to report back stderr

- manual calibration an issue on ipads because of JS events listened to (mousedown vs finger actions)

- Consistent approach routine to homogenize belt tension at destination coordinates

- SVG to GCode converter with optional hatching

- Gondola Plotter support

- Laser engraving implement

- Time estimation

- Load Google fonts locally when not connected to the internet

- Support open & wep networks

- When connecting to managed wifi, be more graceful about refreshing page and having some sort of acknowledgement and waiting animation

- Build for latest Rapios

Hi Ben,

Not even sure this reaches you, but thinking that if you run this on your small device, chances are you are still around.

I’m rebuilding the plottybot since the first time i had a crap 3d printer and everything was misaligning. It has been so long ago it’s hard to follow the circuit diagram.

Would you share the fritzing file, so i can figure out which wires (of same color) go over each other and which should be merged?

I would appreciate it immensely.

Oh I’m around all right :).

here you go: http://ben.akrin.com/downloads/plottybot.fzz

Many thanks Ben

First, this is an awesome project, thank you for your effort and generosity.

I’m done printing parts and am working through the list, preparing to order items. The part ‘belt, stepper gear, lm8uu’ (https://www.amazon.com/KINGPRINT-Printer-Reprap-Bearing-Coupler/dp/B07BMNDDDL) is no longer available, is there an alternate you might recommend? Or individual parts vs a kit?

These Amazon listings are a lot more dynamic than I anticipated sorry. This kit was nice and cheap, but really all you need from it is 8 LM8UU Linear Bearing, a good length of G2 timing belt, and the 20T Timing Pulley that goes on the steppers. These are all *very* standard in the world of 3D printing and very easy to find a bazillion other listing for, in kits or individually.

Thanks so much for your reply. Although I’ve been 3D printing for a few years now, I’m still new to the DIY side of things and familiarizing myself with the components. That’s why this project is so exciting, a huge opportunity to learn and overcome challenges.

Hello, where can you download the SD card? The download link seems not to be working.

I fixed the link, sorry about that. WordPress gets a little finicky when editing such a large page :).

Hi again, I’m still hacking into things and I think I’ve found a bug in the calibration routine. One of my dimensions was always 100mm and it’s coming from the block starting on line 1306.

Does markdown work here?

“`python

if canvas_max_y_steps>canvas_max_x_steps:

canvas_max_x = 100.0

canvas_max_y = 100.0*(float(canvas_max_y_steps)/float(canvas_max_x_steps))

elif canvas_max_x_steps>canvas_max_y_steps:

canvas_max_y = 100.0

canvas_max_x = 100.0*(float(canvas_max_x_steps)/float(canvas_max_y_steps))

else:

canvas_max_x = 100.0

canvas_max_y = 100.0

“`

I’m not sure why the max dimensions should be coupled like that; X and Y dimensions are independent of each other, and why set one to a static value of 100? Also max_ should be a function of `steps_per_cm`, right? I’ve changed mine to this (I don’t think the gondola param is supposed to be used in a tabletop setup based on what I’ve seen in the code but it makes sense mathematically):

“`python

canvas_max_y = canvas_max_y_steps / gondola_steps_per_cm * 10 # x10 to get mm

canvas_max_x = canvas_max_x_steps / gondola_steps_per_cm * 10

“`

and when calibrating on a page of known size it matches my expectations.

Scott, I don’t believe it’s a bug, but it’s definitely a funny decision, and it likely arose from historical code when I was deving early prototypes. What’s going on here is that I want the plotter to always have 100 units. It’s arbitrary, but you could have a big plotter, or a small one, or a gondola plotter and they’d all have 100 units to address. It makes it easier to conceptualize as a human (and to explain to others, I do teach with these). Now of course, more often than not, the plotter was calibrated in the shape of a rectangle, and so I’m setting one dimension to 100 and computing the ratio using the steps for what the other dimension should be. The steps aren’t related to the units you get, they only serve to give you a ratio for an arbitrary unit that really likes 100. As soon as you calibrate, this should be reflected on the web interface and the units will update to what was computed (and the shape of the drawing area will change).

I’m not sure what would happen if you set canvas_max_x and canvas_max_y the way you are. It might just work, but you may have other issues. For example the code I wrote to convert GCode to PCode might have an assumption of 100. Maybe not, I don’t remember off the top of my head.

Thank you for digging in and reporting this. It’s worth mentioning I will soon go through all this code and refactor it some. I’ve been in touch with an organization that’s using PlottyBot in education and it’s made me want to spiffy up this code some. That and I have a couple of other projects that will likely use the same stack so it’s worth the effort :).

Sorry for my late response.

Interesting, so the values don’t necessarily map to real world measurements but in plotter-space you have a normalized distance to use as the reference. That makes sense and definitely not a bug, just a bad assumption on my part. Maybe the solution is to tweak the UI to indicate “hey these numbers aren’t mm”.

The issue I was hitting that lead me to look into it was that my text/image–>SVG–>pcode pipeline includes actual physical dimensions of the resulting SVG, and when I dropped the pcode into the UI the resulting text/image wouldn’t be scaled properly, or at least it didn’t appear to be scaled properly. If I converted a 100mm x 100mm image to pcode I wouldn’t necessarily get a 100mm x 100mm image back out and now I see why: 1mm != 1 plotter unit.

For my own sanity I needed to map real world coordinates to robot coords, and with my patch in place the plotter units displayed in the UI after calibration match the real world dimensions of my work surface. Granted, I haven’t exercised every code path so it’s entirely likely that I’ve broken something somewhere else, but so far it’s working exactly as I would expect.

What is the coordinate frame of the robot? When I’m calibrating manually what are the leftmost and lower edges? The down arrow moves the gondola toward the end with the Pi; is this the lower edge? Left arrow moves the pen head closer to the gondola; is that leftmost?

That’s exactly right.

Posting for posterity and general awareness, there’s a very straightforward way to convert images to plotter code. Download the free version of https://github.com/SonarSonic/DrawingBotV3/tree/master, convert your image to paths and disable all colors except for the darkest. Click on File–>Export per drawing–>gcode. Open the gcode and replace all instances of “G0 Z1” with “(Start cutting path id: )” and instances of “G1 Z0” with “(End cutting path id: )”. Paste the gcode into the interface and you’ll get working plotter code. I’m sure you can get fancier with it but this is incredibly easy and works well for basic images.

those are backwards, should be G0 Z1 –> end and G1 Z0 –> start. Also the user’s python script below that converts gcode directly to pcode is a good way to do this outside of the UI for more control.

Thank you so much for such a detailed project! I’ve just finished building it and everything worked beautifully from the start. The interface is so well done, really good work. I was wondering if the code is on github anywhere; I searched around but didn’t see it, wanted to ask before I go digging around in the Pi image.

I’m afraid you’ll have to dig through the Pi image 🙂 feel free to ask for pointers though. Thank you for the nice words, I always like to hear from people who built one.

I’ve already found everything in the image. Sneaky, it took me a minute since I didn’t see any systemd services, and I like your trick for applying the first boot script, going to file that one away. First order of business is to add a shut down button to the UI, odds are low that the SD card gets corrupted but I’d feel better with a proper shut down instead of yanking the power. I was also curious to see how you handled comms between the front end and back end and was happy to see sockets.

Nice yeah good old rc.local :), nothing sneaky about it really. I’ve gone through several iterations of process initing through the years and rarely have the need to figure out anything other than old reliable rc.local. As for the SD card, I really wouldn’t worry about shut down, the corrupted filesystem fear is one of an ancient era of computing, ext4 is crash consistent, and most of all from experience I have never ever ever ever lost a partition this way. And if I’m proven wrong, it’s not like it keeps important data either. It’s a nice way to get familiar with the code base if that’s what you’re after.

Yes, I do want to dig into the code, especially the front end because that’s where this really shines and it’s a serious weak point for me. I found the gcode_to_turle and draw_turtle_code JS earlier; does the plotter fundamentally parse turtle code to move? I’m already imaging a CLI tool to send an SVG in and have it parse the path and send commands to the plotter over a socket.

Unrelated, but I couldn’t find any plastic suitable for the wire carriers but found that printing strips of PLA 13mm x 200mm x 1mm gave me enough flex to work with. I welded a couple of those together for each axis and trimmed to suit and so far it’s working great.

You’re right it does parse “turtle code” fundamentally, I realized my naming mistake later, it’s not exactly turtle code so sometimes you might see it referred to as “plotter code” or pcode. It’s very much like GCcode just a bit simpler, it’s all fairly simple X,Y coordinates instructions at the end of the day.

Thank you for sharing your trick for making your own flexible plastic, I love it!

Ok my next question was going to be what pcode was, because I was pretty certain that it’s not an intermediate code between assembly and a more abstracted language, and that’s what the internet was telling me 🙂

Last question for now: What flavor of gcode does it speak? I found your sample below and some of the commands aren’t familiar, particularly the `df` preceding the `G0` commands.

No particular flavor, I just read it as a series of X,Y coordinates. Sometimes it’s an issue to map depth to a binary pen up/down, but I adjust whenever some program I’m using spits out GCode that’s different.

I see. I noticed it fails to parse unless I include the (Start cutting path id: ) and (End cutting path id: ) lines, or at least appeared to fail. Other than that the SVG–>gcode–>pcode pipeline seems like it will be pretty straightforward.

Yeah it’s pretty terrible 🙂 that’s what Inkscape spits out at least. It supports a couple of other GCode “formats” I stumbled upon that don’t have the “Start cutting path id” syntax. I’m honestly not sure if there is an official GCode syntax documented anywhere, what I found was a bit of a mishmash and I didn’t have time to launch into a GCode rabbit hole. If you’ve got a format that doesn’t work for you, feel free to send a sample and I can adjust to account for it.

Have we reached max nesting of replies? I can’t reply to your latest message. Anyway, Inkscape explains those weird line beginnings and endings. Re: gcode there’s no “official” version that I know of, but the Marlin index is what I use as a reference. https://marlinfw.org/meta/gcode/

Hi again. Sorry it’s more questions from me…

The PlottyBot has started to do something odd. There are a couple of photos here where you can see what’s happened: https://imgur.com/a/S3G9wdr

In each case, there was an instruction to draw from bottom left corner to top left corner. The pen steadily moved in the y direction as it was travelling so the drawing of all four corners is not rectangular. PlottyBot thinks the top left corner is further to the y than the bottom left corner.

Where should I start looking for the cause?

And something I’ve been meaning to do for ages – I’ve put into Google Drive a pdf of “PlottyBotting for Beginners” so users won’t need to find an md viewer. It’s in the shared folder.

Hey there!

well that’s just completely bizarre 🙂 it looks like a software error but I can’t even begin to theorize about what it could be at the moment.

Do you have the “Plotter Code” that you had it run? I might run into the same issue with my machine. Maybe there’s something about it.

How did you do the calibration? Manually or automatically?

When you say it started doing that, did you run that same code previously and it made a proper rectangle?

Sorry I only have more questions to offer at the moment

And thank you very much for the PDF, I’ve updated the link to point to it.

Gday Ben, thanks for the reply. I’ve added another couple of pics on imgur (same link), the result of the following:

1. Flash a new SD card with plottybot_2021-04-22.img

2. Access PlottyBot over the home wifi and choose manual calibration

3. Set the four sides at roughly the edges of an A4 sheet taped to the bench

4. In pen calibration choose “go to top left”, pen down, then each of the following corners to make a (not!) square

5. Choose pen up

I can see that the top left corner is lower on the page and further to the right than where I set it to be, the lower left corner is where I set it, the two right corners are as expected, and that PlottyBot has successfully gone from bottom left to top left with a straight but slanted line.

As far as I can recall this used to work as expected, but I don’t have any photos to confirm that. If another user follows those same steps, with the same .img, the answer should leap out – hopefully 😉

Next I opened a Mandalagaba session, PlottyBot remaining on with the same calibration. I doodled and got the fourth picture in imgur. The drawing top is about where my top edge was set, and as far as I can tell with my tape measure the drawing has come out square and not distorted.

The “square” in the first picture on imgur showed writing from your handwriting interface, but the frame was drawn afterwards with the manual calibrator doing what I outlined above.

Which all makes me think any issue might lie only in the pen calibration – unless it’s a hardware thing on my build (all too likely, I fear).

I hope that all makes sense, but if you need anything more I’ll do my best to provide it.

Just in case you’re up for a bit of updating: While flashing the new SD card I discovered that Pi Imager now allows users to provide wifi credentials for insertion into the OS image so nobody need attach a monitor and keyboard to the Pi Zero. That was a huge relief to me – every time I’ve disturbed the Pi in PlottyBot, at least one of my soldered connections has come adrift!

Update: No real issue! Here’s what’s happening.

I entered this plotter code to draw a square using the calibration integers from the “Draw” space:

pen_up()

go_to(0,117)

pen_down()

go_to(100,117)

go_to(100,0)

go_to(0,0)

go_to(0,117)

pen_up()

That drew the expected square.

Then PlottyBot moved the pen to the parking spot – which is the same spot as the top left corner of the not-square in the pictures.

So it seems that somewhere along the way, the pen calibration button “top left” actually goes to the parking spot, not the calibrated top left. Everything else continues to work properly – whew!!

Ok ok! I got it :). Sorry it took me so long. You’re totally right that the calibration corners aren’t perfectly lined up. But this isn’t an actual calibration issue and the machine works perfectly. I guess I never really thought that someone would actually draw the square when sending the pen in all 4 corners, I saw this more as a way to adjust the height of the pen in various locations. In fact when going to the corners, the plotter doesn’t go to the actual extremes, it adds some margin so you have a bit of room. So the corners don’t actually serve to reflect extreme positions, it really is just about pen height in a sample of key locations. And so, a while back, I did have a bug where some corners would have the margin and some would not. That is the issue you are seeing. It’s wrong and it’s confusing, I did in fact fix it a few months ago, but I too am running an older image on my go to plotter so I’m seeing the same issue. I’m updating the download links with a version that *I think* has the fix in, if you care to, you can download it again. But really, this isn’t a bug that will affect any actual drawing that the machine will do.

I am aware the the Raspberry Pi imager now lets you bake in settings which is very useful. For the PlottyBot image though, it should span its own Wifi when it isn’t connected to anything, so you can always connect to it without having to plug it into a monitor. From there you can scan for other Wifi networks such as your home wifi and connect to it. You don’t have to, it’s just a bit easier than being connected to the machine direct since it doesn’t route to the internet.

Thank you for your mentioning this new capability, and the bug you found. It’s not critical and it should be updated in the newest release (or it will be in a new new one :)).

Hi Ben!

Thank you for creating this great project. I’m finally starting with my build and I’m really excited about it.

Some parts are unavailable at the moment, I tried to find proper replacements – would you mind to take a look at them?

1. The stepper motor driver:

https://botland.store/stepper-motor-drivers/2660-stepper-motor-driver-a4988-reprap-red-5904422359201.html

It looks like can handle 12v and has the same features in this voltage:

https://unorthodox-engineers.blogspot.com/2013/11/review-more-arduino-motor-modules-a3967.html#:~:text=That's%20really%20the%20principal%20difference,overheat%20when%20you%20go%20above.

I am aware there will be some issues with placing it due to dimensions differences.

2. The stepper motor – I found this replacement – do you think it will work? The torque and current are a bit lower

Steps per Revolution: 200

Step Angle: 1.8 degrees

Current per Coil: 1.7 A

Coil Resistance: 1.5 Ω

Winding Inductance: 2.8 mH

Rated Current: 1.5 A

Number of Wires: 4, bipolar

Holding Torque: 4.28 kg/cm

Body Length: 40 mm

Shaft Diameter: 5 mm

Shaft Length: 24 mm

Dimensions: 42x42x40 mm (excluding shaft)

Weight: 380 g

Thank you so much!

Pawel,

it’s impossible to know for sure without testing first but this looks reasonable. You could always dupont wire just one motor/driver from the circuit as a test to confirm.

Thanks for your quick response! I’ll give it a try and will post some feedback if it works 🙂

I think I put my response in the wrong part of the conversation tree 😉

It took some time to gather everything together, but I’m ready for soldering. Just one question – since A4988 driver (that I will use instead of the one used in the original project) has capability for 1/16 microstepping (MS3 pin) – is it possible to make the adjustment to utilize this feature or is it unnecessary/too complicated/whatever other reason for no-no?

If yes – where should I look up in the code to update it? 🙂

I don’t believe it’ll be necessary, as it stands, the plotter is wired for using the 2 microstepping pins but in hundreds of drawings, I never felt like a full step was too much so I never deviated from it.

There might be a very rare case where it’s useful to enable it some microstepping, but I can’t imagine needing 1/16.

In any case, take a look at /usr/local/bin/plottybot.py and search for “ms1” and “ms2”, or a variable called “step_size”, you’ll quickly find your way to the few spots where this is set. None of is is complicated so it should be easy to tweak.

Good luck!

Hi thank you for fixing the file,

i’m a fan of your project i see you have plans for svg on gcode

you wrote about some doubt,

this project is open source someone used it in blackstripes,

putting svg directly would be very cool

https://github.com/fullscreennl/blackstripes-drawbot-driver/tree/master https://github.com/memononen/nanosvg

sorry for my english i’m not good at this

I thought about having a way to upload an SVG directly into the web interface but it’s not ideal in many regards. Not all SVGs are created equal, some have overlapping shapes, some have fills, some don’t, some unioned shapes, some use color, some groups, et cetera. All of these things can be interpreted differently, and so you can’t have a one size fits all conversion on the drawing machine. I mean you could, but it would lead to unsatisfactory drawings in most of the cases.

In the world of CNC machining, the common language is GCode, and so I thought it’d make sense to let the user come with with GCode with whatever tool they want (there are many). SVGs aren’t even required as a step to GCode, there are tools that don’t use SVGs to get there.

I did accumulate a set of tools to turn SVGs into Gcode in a way that works for me, and each time I convert an SVG to GCode that the tools I use are a little different. While I don’t think it makes sense to have these tools right in the Plotter’s web interface because the process is different every time, I thought I might put some of them online at some point so they can at least be used. It’s also true that these tools tend to be resource hungry and would do terribly on a Pi Zero :).

Thank you for your suggestion.

Hi, how can i use “Dave Evans has contributed a very nice Getting Started document”

i have MarkDown browser but can’t find the file, You can send it to me

I fixed that link 🙂 sorry.

Hi Ben,

Congrats for that amazing project. I am on my way to built one.

Thanks for the kind words. You might be interested in the Gondola version which saw the light of day more recently. It’s easier to build and has the same software stack.

Hey Ben,

During the build time, you can realize how much hard work you have done throughout the project and walkthrough. Only if you try to make it you can realize that… Thanks a lot!

I would like to ask for your suggestions about something, I would like to sign some papers remotely, I can figure out the network part for the remote access but what way would you suggest if I wanted to sign on 3 particular areas on a A4 paper as a template and maybe having saved my signature somehow.

If I’m understanding correctly, the way I’d do this is to use an SVG editor, create a document in A4 and sign the areas you want. I’d save that SVG and convert it to GCode. Inkscape has a (terrible to use but very reliable) way to export an SVG in GCode. Then you can just paste that GCode in PlottyBot’s interface.

Thanks for your answer,

Is there any way I could edit the HTML page?

I forgot to mention that the signatures some time would be on different areas, so I would probably like to embed an RTSP camera stream on HTML and sign from iPad on real time. Does somebody have done this before?

I don’t think anybody’s done this before, but you can indeed change the page. SSH into the Pi with default Raspbian credentials and it’s all user /var/www/html.

Great, thanks a lot. I’ll make my tries and get back.

It wasn’t that easy as I expected.. I can manage to embed the camera string on the web ui, but real time drawing is not an easy job…

At the time I have mess with gcode convertion on macOS… there is no way to convert anything…

Hi Ben,

I just finished building my first Plottybot. First of all, thank you for making these amazing instructions that even I was able to follow. I had so much fun building this and it will be so helpful once I can get it to work.

I was hoping you or someone can help me with two issues I am having.

1. If any of the limit switches get activated it causes the whole thing to spaz out. I am assuming I swapped the servo wiring accidentally.

2. Only pen up and down commands are being executed and it skips “go to” commands. This is true both on my phone and PC. It does execute the ‘test bottom/top servo” in the “mechanics” section without any problems.

Thanks in advance!

-Avi

Hey Avi,

1. I’ve had this happen and it was in my case due to improper wiring. I can’t remember exactly but I want to say it was a ground pin solder that was touching another pin. You should be able to use the plotter regardless by using the manual calibration which does not rely on the limit switches. I use manual calibration all the time to exactly define the boundaries of the piece of paper I’m working on. That’s not to say you shouldn’t check your wiring 🙂 but you can do without if it turns into a headache.

2. the command is supposed to be “go_to( x, y )” not “go to( x, y )” (note the underscore). You should see a rendering of the drawing the machine is about to do, if you see that rendering and the machine doesn’t draw it, there’s a deep issue somewhere :). If you don’t see it, you need to adjust your PCode. Here’s an example for a simple square that should be a starting point:

go_to( 10, 10 )pen_down()

go_to( 10, 90 )

go_to( 90, 90 )

go_to( 90, 10 )

go_to( 10, 10 )

pen_up()

Does this help?

Hi Ben!

Thank you so much for the quick response!

I was using the manual calibration but I was mixing up the directions which caused it to skip all of the “go_to” and only read the pen up and down commands. It was frustrating but also a little bit funny. I found a gcode example that you sent in response to a previous comment and now that I have the calibration working, the plotter is working beautifully.

I think you are right about the wiring issue but since it is working now, I will leave it be.

I am still working out how to export lines from Rhino to a flavor of gcode that the plottybot is willing to use but I will figure it out.

Thanks again! I am a huge fan of everything you do and will continue to follow and be inspired.

I think I understand what happened with the manual calibration, thank you for describing it. It ended up with a canvas size of zero (or negative size), it ran the go_to commands but there was nowhere to be in zero space. That’s really good to know and clearly a lack of error checking on my part, I’ll improve

Could you please send me a sample of the GCode you are able to produce from Rhino? I very half-bakely threw a parser together and it’s really not up to par. I’m more than happy to make sure other flavors are supported. And this way you don’t need to worry about it :).

Thank you for the kind words.

At some point in the middle of the night, I figured that because I had wired the stepper motors in reverse I was manually setting the workspace to zero or negative. That can also explain the behavior of the limit switches. I think it is hitting a limit switch and telling itself to back up a bit but instead, because it is reversed, it is going right back into the limit switch and then it gets stuck in a loop and starts to dance. This sounds like what Alex B, the previous commentator described.

As for the gcode,

So far the plan was to export lines from rhino and then use Inkscape which according to other comments here seems to be the way to go. So far the gcode that it is exporting looks like this:

G01 F2100.0 X106.946 Y150.119; draw !!Xleft+106.946 Ybottom+150.119

That does not look like your example. I also tried a few svg to gcode online tools but none of them worked either.

Hi Ben, I’ve been a silent watcher on this project for the past 9 months or so, slowly gathering my parts etc. I’ve finally finished my build, quite exciting. However, I’m running into an issue that I’m not sure how to solve. When calibrating, either automatically or manually, the plotter moves to it’s top position, crashes into the limit switch and keeps going, grinding and slipping on the belt until I (hastily) remove power. I’ve tested the limit switches as per the instructions, I’m just not sure whats going wrong. Any help would be amazing. Cheers 🙂

Hey Alex, I’ve actually had this on one of my prototypes, let me see if I can remember the steps I went through :).

First of all, when calibrating manually, you are not supposed to run into the limit switches. This is meant to define boundaries smaller than the plotter allows. In fact I only ever use this mode of calibration because my sheets of paper are always smaller than the plotter. And so when you say that the problem also occurs with manual calibration, do you mean you hold the button all the way up to the limit switch? Or do you mean that there is a problem where the plotter keeps moving even when you release it, and then it bumps into the limit switch?

If it’s the former, I would say your next step is to actually do a manual calibration on some piece of paper, not running into the limit switch. And actually have it draw something. This will tell us that hopefully the plotter moves fine and it’s not a stepper motor issue, but really a limit switch one.

I want to say, that I had a limit switch with some contact with another wire/pin where it was soldered on the Pi, and that wreaked havoc on the circuit when it was triggered, resulting in erratic stepper motion.

I’m assuming, but maybe I shouldn’t so I’ll ask anyway, you are certain that the limit switch is getting triggered right? Is it possible that its tongue is too far in and actually not getting pushed all the way so the plotter keeps ramming into the terminal? As you launch the calibration you can trigger it by hand to see if it sends the plotter in the other direction or creates that same issue.

to recap, my recommendations are:

1. make sure the limit switch is getting pushed all the way and triggered by the plotter

2. try to calibrate manually without the limit switches, make sure motion is without issues on a drawing

3. check where limit switches are soldered and make sure there is no contact with other pins

I hope this helps.

Hi Ben, thanks so much for your speedy reply. I’ve done a little more investigating, but still yet to solve the issue. I have managed to get it to plot something which is very exciting!

So I’ve checked that the connections aren’t touching, I’ve used dupont connectors but heatshrinked the ends instead of using the plastic sleeves.

Today when I tried to manually calibrate it, it definitely moved by itself after clicking the button in the webUI. (It when to the top and jammed again). After this, I tried checking the switches again from the webUI, and noticed that this time when I manually pressed them, the plotter would move toward whichever switch was being pressed, constantly, while it was pressed. Not sure if this is intended behaviour? (I have a short video of this if it’s of interest)

I did also make sure the switches are being pressed by the gondola, there’s a few mm clearance at every end.

Lastly, and not sure if this helps, but I noticed that when using the buttons to jog the plotter, these are all reversed, I didn’t think much of it at first, however now I’m wondering if I’ve got the steppers wired in wrong or something? Although it did plot something correctly, so I’m not sure about that.

The other weird issue I ran into, is the box box doesn’t seem to like space characters? I checked the browser console, and see the a message being logged “TODO: should we replace the char with a space?” It can’t read the length property of ffont[next_unicode] it seems? I didn’t delve too deep into that.

Again I really appreciate your help with this, it’s my first project of this type so it’s quite interesting 🙂

Ha! so I just did a little test, and manually pressed the opposite limit switches before the gondola reached it’s end and it worked, so I must have the steppers wired up in reverse or something. I’ll try swapping the wires over and that should fix that. Do you know if I should swap A+ with A- (And B+ with B-) or should I be swapping A+ onto B+ and A- onto B-? Hopefully that makes sense ha

As for the error with the space characters, still not sure about that.

Great news! I’m glad it’s as simple as reversed motors. I check the circuit diagram many times over, and several people went through the build so I’m pretty confident it’s right, but if it isn’t please let me know and I can check again.

In terms of swapping motor connections, ideally you can “get it right” from the circuit diagram. But I know stepper motors are terribly inconsistent and poorly documented. I will say this to answer your question more directly though:

– if it’s moving (doesn’t if the direction is right), I think you got the 2 coils on their proper A or B pins. You don’t want to swap A pins with B pins.

– I’m not sure why, but I bet if you swap either A+ with A- or B+ with B-, either will reverse the direction. I was trying to find an empirical way to figure out coils and polarity. It’s easy to figure out coils with the LED test (https://ben.akrin.com/driving-a-bipolar-stepper-motor-with-an-l298n-and-a-raspberry-pi/). As for polarity, I couldn’t find a method, but it doesn’t matter, the worst that will happen is that the motor will go in the wrong direction and so you can just swap a coil.

I can’t say for sure these conclusions are true for this EasyDriver stepper driver, but I do think they are a general truth of stepper motors.

For the handwriting stuff, I’ve revisited the code recently, but didn’t publish the changes for the PlottyBot yet. This image is untested, but if you are feeling like contributing back some, please try this: https://ben.akrin.com/downloads/gondola_plottybot_2023-01-31.img

Just replying to my own comment, mostly so if someone else runs into the same issues maybe this will be useful..

In short, I worked out both of my problems, first, I reversed the polarity on the steppers by simply swapping a single pair around (A+ to A- and vice versa)

The issue I was facing with the space characters I realised was because I hadn’t set the space character in the font file. I only realised this after seeing the trailing slashes on all the special characters and then noticing there was a trailing slash seemingly by itself in the last box. Of course now that I think about it it makes perfect sense to set your space width.

Just needs some fine tuning but otherwise I think it’s good to go! (Just need to print a new pen holder as I broke mine after tightening it slightly too much 😛 )

Just a thought Ben, but perhaps adding some tooltips in the UI may be helpful 🙂

great, and yes, documentation is lacking. There is a serious effort in the hardware, software and build documentation, and I’m only 1 man. It’s on the todo list :).

Hi Ben,

Thought I’d reach out as I’m back to working on building my plottybot. The last few days I’ve been working on redrawing the parts in solidworks so you’ll have something that’s more easily shareable but I’ve also made a few changes too, with the main aim of removing the need for supports. I’ve got the terminal ends left to finish working on and then I should be in a position to share. I’ve changed the servo holder so a larger MG90 fits. I’ve also changed the belt holding so the head can be removed without the belts coming undone. I also wanted to ask about the belt path at the terminal end. When looking at the model, the motors appear lower than the belt path in the gondala, is that something you’ve noticed?

Feel free to drop me an email if you want some early models or more info.

Jay

Hey Jay,

I think you’re right about the MG90, in my testing it’s been infinitely more robust and thus worth the extra $$. And it does mean the model should be adjusted to this effect.

As for removing support, I do want to maintain editorial discretion 🙂 but I can at least put your version online with your comments. I was considerate of support, but in some cases I just really thought it to be worth the trouble. I’m curious to see what you’ve come up with.

For the motor height, in the instructions I mention a pulley placement where the belt is essentially at the top of the stepper motor shaft: https://ben.akrin.com/wp-content/uploads/2020/12/IMG_1720.jpg

I did consider belt height being consistent throughout, but maybe I missed something? Or maybe it just depends on how you install your pulley.

I’m looking forward to seeing your changes. Take care.

Hi Ben,

really great design and write-up, appreciate it! Would it be possible for you to share the CAD in the fusion360 file format or as a simple step? I don’t own a sketchup licence and would like to dabble a little bit in the CAD and have a look around how you designed things 🙂

I only have the free fusion360 licence and I can’t import the skp file unfortunately.

Cheers

gerold

Hey Gerold,

from Skectchup it looks like I can export to:

– 3DS

– Collada

– DWG

– DXF

– FBX

– KMZ

– OBJ

– VRML

– XSI

Would any of these work for you? Otherwise Sketchup does have a free tier.

Hi ben, sorry I just sow that you sou replied 🙂

Is there no option to export as stp/step?

Otherwise maybe OBJ could work.

Thanks,

Gerold

No sorry, the list I gave you is “all” that can come out the Sketchup. I emailed you the Obj, I hope it scratches your itch. Take care.

I see you made a post in your blog about how the plottybot software will work for a gondola printer. Do you have a writeup for making the gondola printer? Would love to make one for my classroom.

I don’t currently no sorry, I just built the first somewhat legitimate prototype but there’s a few things I need to finalize before I’m ready to publish it. Right now it’s tricky to iterate because of Pi availability and 3D printer being down, that’s why I built this in between version so I could at least take some steps and figure out the code.