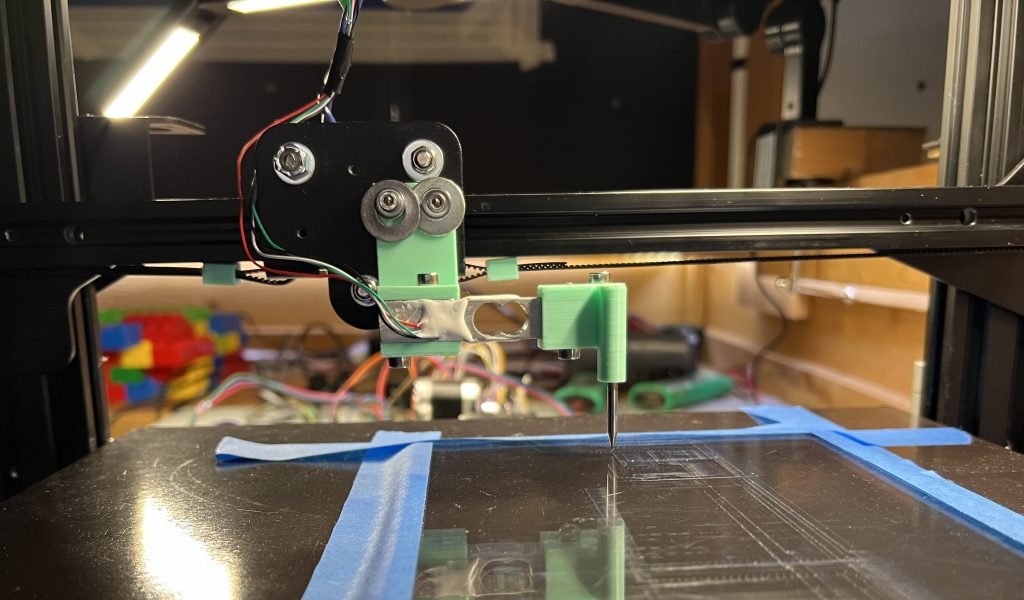

I’ve had mitigated results with my specular holographs, I ran several trials, and only one was really worthy so far. I’ve learned a few lessons, but I’ve had enough success that I want to spend time and resources refining. The way the tip action worked so far was very blunt, I rigged a servo on a 3D printer which could instead have 2 steppers driving the pen up & down action. But that was an easier first step for my plotter stack. So the obvious thing to refine first is to replace the servo with the existing steppers, which is more of a programming challenge. And that part wasn’t too bad. What was much harder though, is how to move the tip so that it presses against the medium with defined and reproducible pressure. With the variations I can’t just “count steps”, and some media (acrylic) require very little pressure, unlike aluminum which was more forgiving. So I know I want to experiment with tip pressure, which means getting a load cell. And that on the other hand was a whole can of coding worms. I won’t go into the boring details, what matters is that it’s etching!

I have the tip go very carefully down until it reaches a pressure of 20g, and then it tries to maintain it while moving. Between the incessant taring, and the slow motions, it’s made everything a thousand times slower. I don’t care though, I can do other things while it works.

The machine makes really cool noises with all the extra stuff to find the right pressure. Simply keeping an ear out while doing other things has been a great tool to debug and improve algorithms.