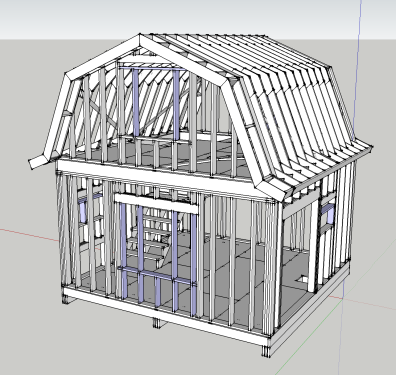

Since the modifications I’m making to the house now are quite specific to our living arrangements, I’ve stopped updating the 3D model I made to design the house. I’ve also gained in confidence and experience such that I don’t need to do everything virtually before I grab a hammer.

Before launching into this adventure, I spent a good deal of time online reviewing designs, techniques and best practices. In case this is useful to someone else I’m publishing the core design here. This design was critiqued over multiple iterations by many carpenters, builders, furniture makers & all around smart handymen.

A few points:

- it is very modular

- a few features are specific to us

- the gambrel design is balanced (every angle 22.5 and equal lengths)